Product Overview

The DZ-1100 Computer Continuous Rolling Vacuum Packing Machine is a cutting-edge industrial equipment engineered for high-volume, continuous packaging operations. As a leading continuous rolling vacuum packaging machine, it combines German precision technology, durable materials, and intelligent control to deliver efficient, consistent vacuum sealing for diverse products. Equipped with a high-performance German vacuum pump and waterproof computer control system, this machine excels in preventing oxidation, mold, and moisture damage—extending product shelf life while ensuring packaging integrity. Its continuous rolling design eliminates downtime between batches, making it perfect for large-scale food processing plants, central kitchens, and manufacturing facilities requiring non-stop production.

Key Features

Superior Material & Durable Structure

Constructed with 3042B food grade stainless steel plate, the machine is resistant to high temperatures (up to 800℃) and corrosion, meeting strict industrial hygiene standards.

Brake angle feet ensure stable operation during high-speed packaging, avoiding vibration and displacement.

High-Efficiency German Vacuum Pump

Adopts a German vacuum pump with a pumping rate of 200 m³/h—providing powerful, stable vacuuming performance while reducing noise and air pollution.

Thorough air removal prevents product spoilage and maintains freshness, ideal for long-term storage and transportation.

Advanced Waterproof Computer Control

Features a waterproof computer Chinese character control system (reaching international advanced levels) with a PLC operator panel and programmable human-machine interface.

Intuitive operation allows quick setting of packaging parameters, supporting continuous adjustment for different product types.

Stable & Scratch-Proof Packaging System

Uses PVC high-quality soft bottom track with aluminum alloy fixation to prevent packaging bag scratches, ensuring a neat, professional appearance.

Silica gel sealing material delivers high sealing performance and durability, maintaining tight seals even after prolonged use.

Reliable Safety & Transmission Technology

Equipped with an emergency stop button for immediate shutdown in case of abnormalities, protecting operators and equipment.

Adopts the latest Faulkson transmission technology—ensuring smooth, efficient operation and reducing wear for long service life.

Technical Specifications

Parameter | Details |

Model | DZ1100, DZ1000 |

Brand | HUIYILAI |

Material | 3042B food grade stainless steel plate |

Vacuum Pump | German-made, 200 m³/h pumping rate |

Control System | Waterproof computer Chinese character control, PLC operator panel |

Sealing Material | Silica gel |

Track Material | PVC soft bottom + aluminum alloy fixation |

Transmission Technology | Latest Faulkson technology |

Safety Configuration | Emergency stop button |

Stability Feature | Brake angle feet |

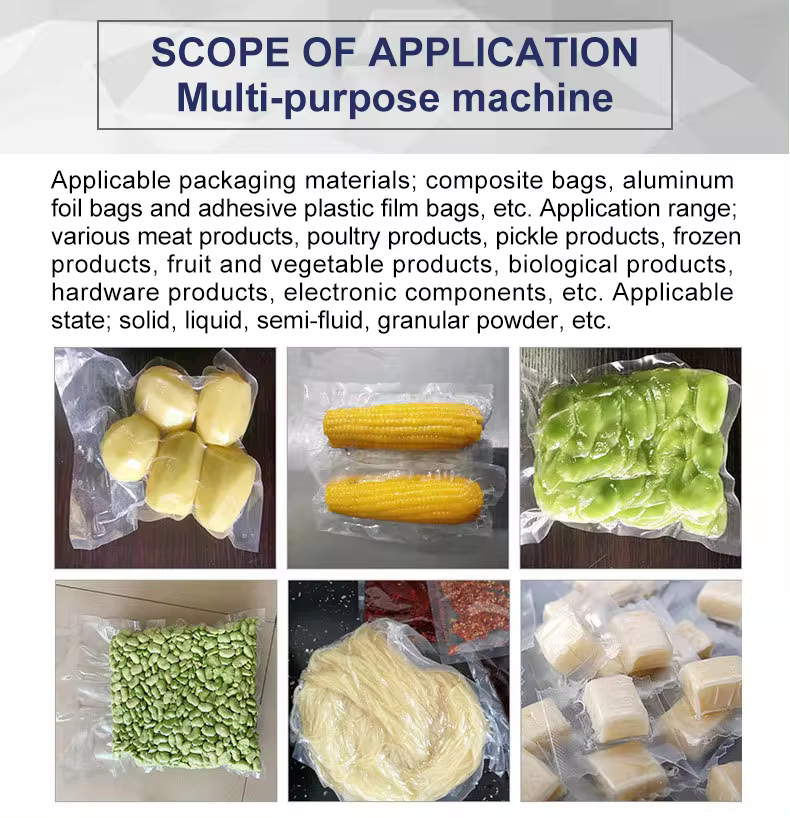

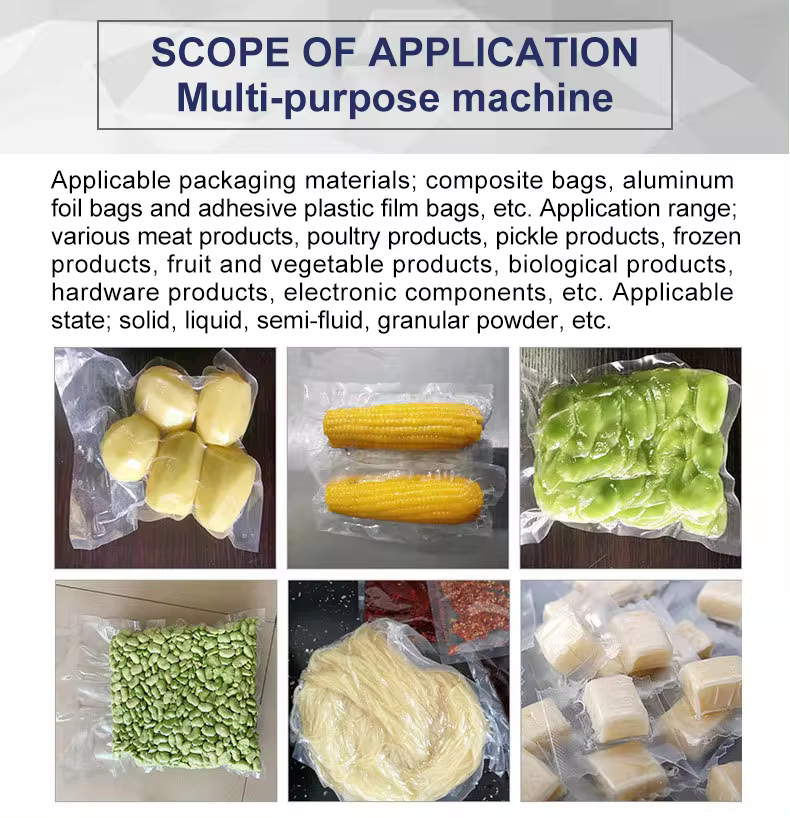

Applicable Product States | Solid, liquid, semi-fluid, granular powder |

Packaging Materials | Composite bags, aluminum foil bags, adhesive plastic film bags |

Application Areas

Multi-Industry Compatibility

Food industry: Perfect for meat products, poultry products, pickle products, frozen foods, fruit and vegetable products, tea, and fast food—suitable for solid, liquid, semi-fluid, and granular powder states.

Medical & chemical industry: Ideal for medicines, biological products, and chemical raw materials—protecting against moisture and oxidation.

Hardware & electronics industry: Suitable for hardware products, electronic components, and precision instruments—preventing corrosion and damage.

Applicable Facilities

Corn processing plants, net vegetable processing plants, meat processing plants, central kitchens, large-scale food processing factories, and research institutions requiring high-volume packaging.

Operation & Safety

User-Friendly Operation

PLC operator panel with a programmable human-machine interface simplifies parameter setting—no professional skills required for operation.

Continuous rolling design enables non-stop packaging, eliminating batch-to-batch downtime and boosting production efficiency.

Comprehensive Safety Measures

Emergency stop button provides instant shutdown capability, minimizing risks during abnormal operations.

Brake angle feet ensure stable positioning, preventing equipment movement during high-speed packaging.

Food-grade materials and sealed electrical components comply with industrial safety and hygiene standards, avoiding contamination.

Customization Support

The DZ-1100 Computer Continuous Rolling Vacuum Packing Machine offers flexible customization to meet specific production needs:

Model selection: Choose between DZ1100 and DZ1000 based on production volume and workshop space.

Packaging material adaptation: Customize to fit specialized packaging materials beyond standard composite bags, aluminum foil bags, and adhesive plastic film bags.

Control system customization: Add specialized functions to the computer control system, such as automatic batch counting or parameter storage.

Size adjustment: Tailor the machine’s dimensions to fit unique workshop layouts or large-scale product packaging requirements.

FAQ

What packaging materials can this machine use?

It is compatible with composite bags, aluminum foil bags, adhesive plastic film bags, and other common packaging materials—suitable for diverse product packaging needs.

Is this machine suitable for central kitchens?

Yes, it is ideal for central kitchens due to its continuous packaging capability, efficient vacuuming, and easy operation—supporting large-scale meal preparation and fresh-keeping.

How to maintain the machine’s sealing performance?

The silica gel sealing material is durable; regular cleaning (to remove residue) and occasional replacement (when worn) will maintain optimal sealing performance. We provide guidance on maintenance during after-sales service.

What is the noise level during operation?

The German vacuum pump is designed for low noise—effectively reducing operational noise and air pollution, creating a comfortable workshop environment.