Product Overview

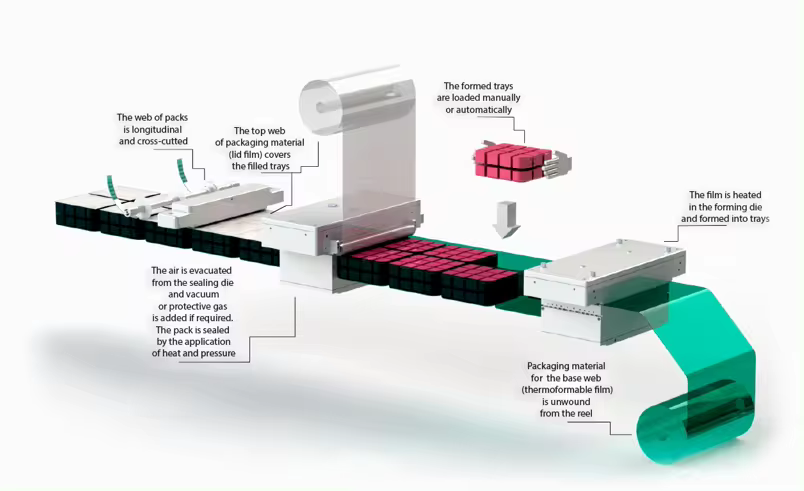

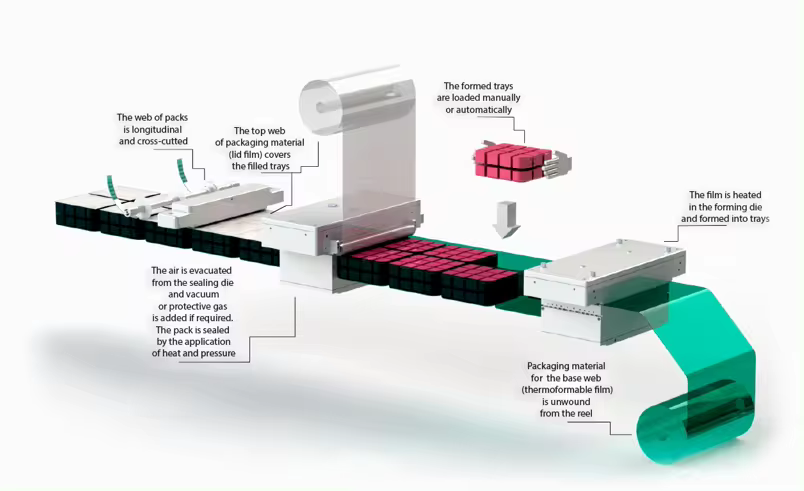

This Automatic Vacuum Sealing & Thermoforming Machine is engineered for high - efficiency packaging in large - scale food production. Tailored for processed foods like meat, poultry, and seafood, it integrates vacuum sealing and thermoforming technology. With a compact, modular design, it fits seamlessly into existing production lines, enabling high - speed, automated packaging with minimal manual input. It enhances product shelf - life, maintains freshness, and ensures consistent, high - quality packaging results.

Performance Advantages

1.Automation & Intelligence

Automatic Feeding System: Ensures uninterrupted material feeding, optimizing workflow for large - scale operations.

Intelligent Control Technology: Automates process adjustments, maintaining optimal settings throughout production.

Automated Fault Detection: Rapidly identifies and diagnoses issues, reducing downtime and simplifying maintenance.

Laser Inkjet Printing: Enables automatic, clear labeling, streamlining the production flow without manual intervention.

2.Precision & Consistency

Precise Quantitative Filling: Guarantees accurate portioning, boosting efficiency and minimizing material waste.

Three - Color Sensor Tracking (Imported): Delivers precise color detection, enhancing alignment and consistency during packaging.

Precision Positioning Drive: Ensures accurate positioning, improving operational accuracy and production consistency.

3.Durability & Reliability

Aviation - Grade Alloy Build: Constructed with high - strength alloys for exceptional durability and long - term use.

Custom - Designed Steel Chain: Offers smooth, durable performance, reducing the need for frequent repairs.

Wear - Resistant Bearings: High - quality bearings minimize maintenance and extend machine life for continuous productivity.

High - Performance Electrical Cabinet: Provides a reliable electrical system to withstand demanding production environments.

Top - Tier Vacuum Technology: Utilizes advanced engineering for superior vacuum sealing, enhancing product preservation.

Competitive Edge

When compared with similar machines in the market:

Efficiency: Its automatic feeding and intelligent control outperform many rivals, ensuring a more seamless and continuous production process. The precise quantitative filling also reduces material waste to a greater extent, saving costs for large - scale production.

Precision: The three - color sensor tracking and precision positioning drive offer more accurate packaging alignment and portioning. This leads to a higher rate of consistent, high - quality products, which is crucial for brand reputation in the food industry.

Durability: The aviation - grade alloy build, custom steel chain, and wear - resistant bearings make it more durable. It can operate stably for a longer time with less maintenance, reducing the total cost of ownership compared to machines that may require more frequent part replacements and repairs.

Technology Integration: The combination of advanced vacuum technology, laser inkjet printing, and intelligent control systems integrates more comprehensively to meet the diverse needs of food packaging, from preservation to labeling, giving it an edge over competitors with more fragmented functionality.

Application Scope

Specifically engineered for the food industry, it provides reliable sealing for perishable goods such as meat, poultry, and seafood. Creating an airtight seal locks in freshness, extends shelf - life, and suits high - output production lines. It offers flexible packaging options like thermoformed trays and stretch film, adapting to different product types, sizes, and shapes. Whether packaging fresh cuts, frozen items, or ready meals, it delivers consistent results, boosting production efficiency and ensuring optimal product preservation.

Production & Delivery

Production Facility

The manufacturing facility is built for high - demand production. Equipped with cutting - edge machinery, every step from material handling to final packaging is optimized for speed and precision. The layout ensures smooth operations, and the integration of skilled operation and advanced technology maintains exceptional quality, meeting the rigorous standards of the food packaging industry.

Delivery

The machine is delivered safely and promptly using secure packaging methods. Each unit is encased in robust wooden crates to prevent damage during transport. Clear labeling streamlines customs processes for fast and efficient delivery, ensuring a smooth experience so you can focus on business growth.

Shipping & Payment

Fast and secure delivery options are available, including air, sea, or road transport. With a reliable global network, orders reach safely and on time worldwide. Trusted payment methods like PayPal, T/T, L/C, and Western Union simplify the purchase process, making the entire experience seamless for running your business efficiently.