Product Description

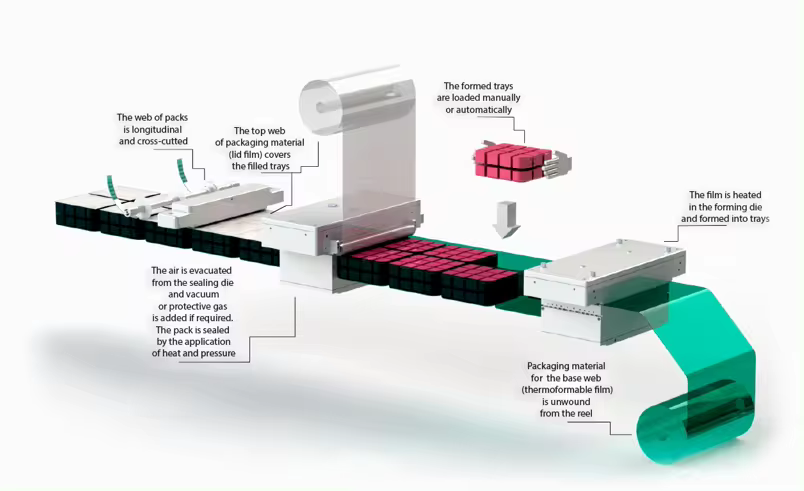

The Stretch Film Vacuum Packing Machine is designed for large-scale, automated packaging of processed foods. Widely adopted by food processing industries, this machine uses advanced technology to provide efficient vacuum sealing. The stretch film system ensures strong, secure packaging, preserving the freshness and quality of food products. This machine is ideal for high-volume operations, offering automated production with minimal manual intervention, increasing overall productivity. It's particularly suited for products that require vacuum sealing, ensuring a tight seal for optimal preservation.

Performance Advantages

AF Automatic Feeding System: Efficiently loads products, reducing manual input.

Automatic Quantitative Canning System: Ensures precise and consistent filling.

Intelligent Computer Control: Offers precise control over the entire process.

Advanced Sensor Tracking: Features a U.S.-imported three-color sensor for accurate monitoring.

Siemens Three-Proof Electrical Cabinet: Provides durability in harsh environments.

Laser Ink Jet Printing: Automatic, precise printing for enhanced product labeling.

High-Strength Alloy Body: Aviation-grade custom alloy for added strength and longevity.

Intelligent Fault Processing: Computerized system for quick diagnostics and error handling.

Customized Fine Steel Chain: Durable, tailored for smooth, continuous operation.

Swiss Wear-Resistant Linear Bearings: Ensures smooth, low-maintenance performance.

Siemens Drive Positioning: Guarantees precise positioning for consistent results.

German Vacuum System: Original system for efficient, high-performance vacuum sealing.

Scope application:

The stretch film vacuum packaging machine is ideal for high-volume packaging in the food processing industry. It is particularly effective for meat products, such as chicken, beef, and pork, as well as prepared foods like ready-to-eat meals and snacks. The machine ensures optimal vacuum sealing, preserving product freshness and extending shelf life. It also meets the packaging needs for poultry, seafood, and other perishable goods, making it essential for efficient food packaging processes.

Workshop:

Our production facility is equipped with advanced, high-efficiency machinery to ensure consistent and precise manufacturing. The spacious layout allows for streamlined workflow, optimizing production capacity. Our workshop features multiple production lines for stretch film vacuum packing machines, designed for high-volume food packaging. This setup supports rapid scaling while maintaining quality standards, making us capable of meeting diverse customer demands.

Delivery:

Our products are securely packaged and shipped in robust wooden crates to ensure safe transportation. Each unit is carefully labeled for easy identification, and we guarantee on-time delivery to your location. Our logistics process is streamlined for efficiency, minimizing any potential delays during transit.