Overview

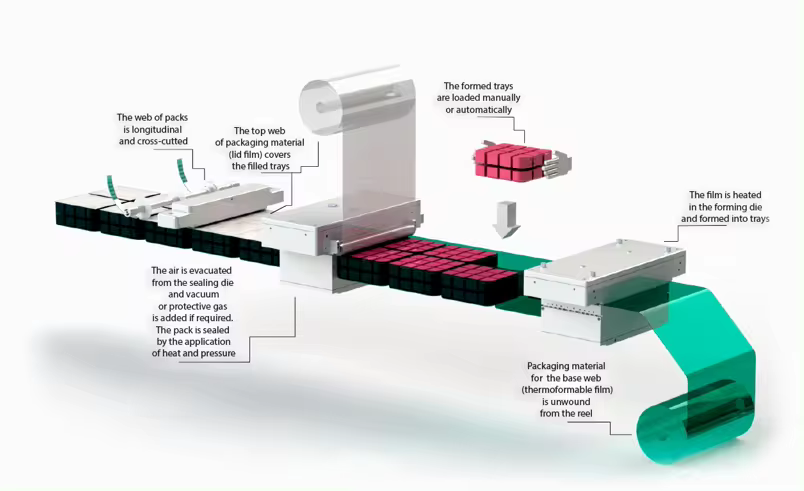

The Industrial Automatic Dates Thermoforming Vacuum Packaging Machine revolutionizes date packaging with fully automated tray forming, filling, and sealing. Designed for sticky, irregular products, it uses a heated thermoforming process to create custom-shaped trays from PET/PE films, followed by vacuum sealing to protect dates from moisture and insect infestation. With a throughput of 30-40 trays per minute, it balances speed with precision, ideal for large-scale date producers and exporters.

Features

Servo-Driven Thermoforming: Precision heating (180-220°C) and mold forming create trays with 3mm wall thickness, supporting weights up to 500g per tray (e.g., pitted dates, date bars).

Anti-Stick Filling System: Vibratory feeder with Teflon-coated chutes and vacuum-assisted pick-and-place ensures accurate date placement without sticking, even for glazed or sugared varieties.

Deep Vacuum Sealing: Achieves <1% residual oxygen with optional nitrogen flush, extending date shelf life from 6 to 18 months in ambient storage.

Film Waste Recycling: Integrated edge trimmer reclaims 90% of scrap film for re-grinding, reducing material waste and production costs.

Remote Diagnostics: Built-in IoT module allows real-time monitoring of film tension, seal temperature, and reject rates, with predictive maintenance alerts for blade wear.

Application

Date Processing Plants: Packages fresh, dried, and stuffed dates (e.g., with nuts, chocolate) in retail-ready trays, meeting USDA and EU organic certification standards.

Confectionery Packaging: Forms trays for energy bars, nut clusters, and other sticky snacks, with tamper-evident seals for consumer safety.

Export Packaging: Creates moisture-proof packaging for international shipping, protecting dates from humidity during transit (ideal for Middle East, North Africa markets).

Private Label Services: Customizable mold designs and film printing options (up to 8 colors) for brand differentiation and shelf appeal.

FAQ

Q: How quickly can the mold be changed for different tray sizes?

A: Tool-free mold changeover takes <15 minutes, with automatic recipe recall for heating and forming parameters.

Q: What is the maximum film width?

A: Standard model handles 500mm wide films, with custom versions available for 800mm width (suitable for jumbo trays).

Q: Can it package wet dates (with syrup)?

A: Yes, optional anti-spatter sealing bars and deeper tray molds (up to 40mm depth) accommodate liquid-containing products.