Commercial Automatic Frozen Meat Slicer Machine Added Value Food Automatic Meat Cutter Slicer Machine

Professional Frozen Meat Processing and Food Cutting Equipment for Commercial Use

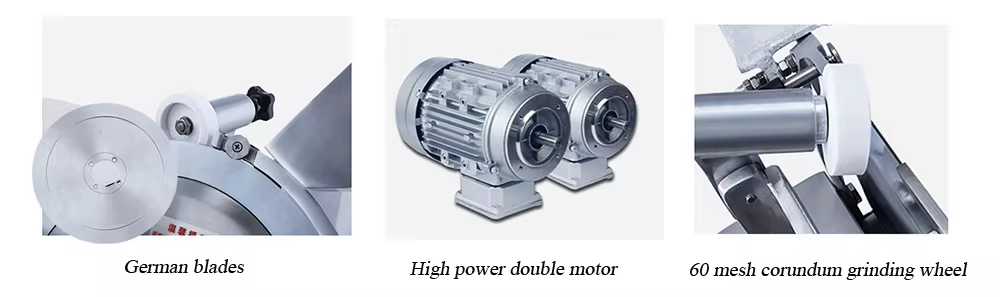

The industrial meat slicer machine integrates advanced cutting technology. Each commercial meat slicer manufacturer prioritizes food safety standards. The automatic frozen meat cutter maintains precise slicing control. Professional meat cutting machine features triple safety protection.

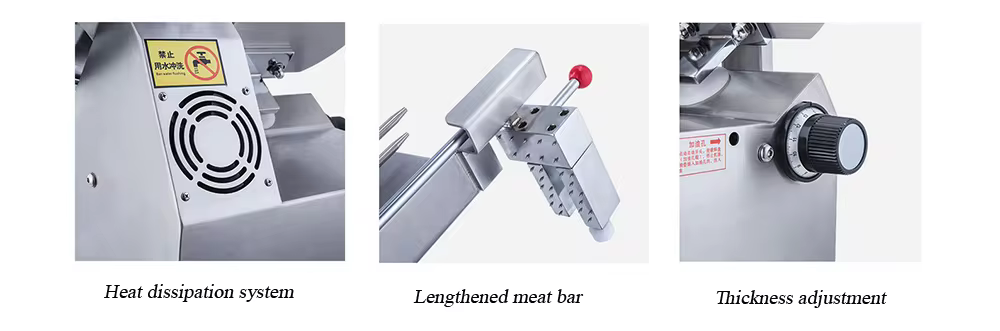

Our meat processing equipment supplier implements smart feeding mechanisms. The industrial food slicing machine offers adjustable thickness settings. Commercial food cutter includes auto-reset functionality. Digital controls ensure consistent cutting precision.

The frozen meat processing equipment features spiral structure design. Premium stainless steel construction enhances durability. Multiple blade options accommodate various meat types. Automated feeding system improves operational efficiency.

This commercial meat processing machine includes safety interlocks. The professional cutting system reduces material waste. Enhanced blade design processes frozen products effectively. Customized solutions meet specific production requirements.

| Parameter | Value |

| Material | SUS304 Stainless Steel |

| Cutting Thickness | 0.1-99mm Adjustable |

| Safety Features | Triple Protection System |

| Blade Options | Flat/Serrated Blades |

| Control System | Digital Touch Screen |

| Processing Capacity | 500kg/hour |

| Power Supply | 380V/50Hz |

| Machine Size | 1200×800×1100mm |

| Protection Grade | IP65 |

| Warranty | 12 Months |

| Certification | CE, ISO9001 |

| Application | Meat Processing Plants, Food Service Industry |

Essential Features of Professional Commercial Meat Slicer and Food Processing Equipment

Advanced Technology Integration

Industrial meat slicer machine features digital thickness control system

Automated feeding mechanism enhances processing efficiency

Smart blade adjustment adapts to various frozen meat types

PLC control system ensures precise cutting operations

Real-time monitoring displays operational status

Safety and Hygiene Standards

Commercial meat processing equipment includes triple safety protection

Food grade stainless steel construction prevents contamination

Emergency stop function ensures operator safety

Quick-release blade system simplifies cleaning procedures

Sealed electrical components protect against moisture

Production Efficiency

Professional meat cutting machine processes up to 500kg per hour

Adjustable speed settings match different product requirements

Continuous feeding system reduces operational downtime

Multiple blade options maximize cutting versatility

Compact design optimizes workspace utilization

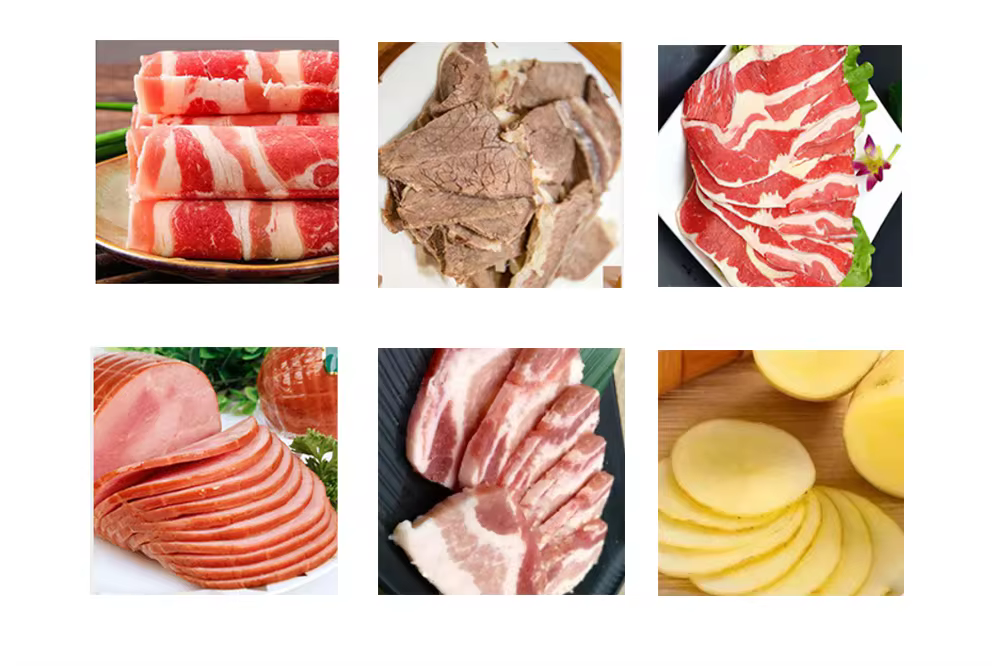

Industry Applications

Meat processing plants achieve consistent slicing quality

Food service providers maintain portion control

Supermarket meat departments enhance productivity

Industrial kitchens increase processing efficiency

Frozen food manufacturers ensure uniform cuts

Food distribution centers streamline operations

Maintenance Features

Tool-free component access simplifies daily cleaning

Quick-change blade system reduces maintenance time

Modular design enables easy parts replacement

Self-diagnostic system identifies maintenance needs

Regular calibration ensures cutting precision

Scope Of Application

Packing&Delivery

Shipping&Payment

FAQs

Q1: How do I adjust slice thickness on the commercial meat processing equipment?

A1: Our digital control panel allows precise thickness adjustment with one-touch operation for consistent cutting results.

Q2: Does the industrial meat slicer work with both fresh and frozen products?

A2: Yes, our professional cutting machine handles fresh, chilled, and frozen meats with interchangeable blade options.

Q3: What cleaning procedures are required for the food grade slicing equipment?

A3: Quick-release components and tool-free access enable daily sanitization within 15 minutes following food safety standards.

Q4: Can the automatic meat cutter process different meat products without adjustments?

A4: Smart blade technology automatically adapts to various meat textures, maintaining consistent cutting quality.

Q5: What service support comes with the commercial food processing machine?

A5: We offer installation, operator training, customization options, and 24/7 technical support throughout warranty period.