Product Details: Hydraulic Poultry Marinator for Commercial Meat Processing

Product Overview

The Hydraulic Poultry Marinator Series offers a complete range of vacuum tumbling machines designed for food factories, meat processors, and catering chains. Whether you need a compact 10L model for small-batch testing or a high-capacity 2000L machine for industrial-scale production, this series delivers consistent performance with hydraulic lifting and vacuum marination technology.

Product Description

Unlike traditional soaking methods, the Hydraulic Poultry Marinator uses vacuum negative pressure to open up meat fibers, allowing brine, spices, and marinades to penetrate faster and deeper. This ensures enhanced tenderness, juiciness, and uniform flavor distribution.

The machine’s hydraulic system provides smooth drum rotation, even with heavy loads, while the adjustable roller speed makes it versatile for poultry, beef, pork, seafood, and deli meats. All models are built from SUS304 stainless steel, ensuring hygiene and long service life.

With capacities ranging from 5 kg to nearly 1 ton, processors can select the right model according to their production scale—from R&D labs and restaurants to fully automated food factories.

Key Features & Highlights

✔ Wide Capacity Range (10L–2000L) – From small-batch marination to industrial bulk processing.

✔ Hydraulic Drum Design – Stable and reliable rotation for heavy-duty use.

✔ Vacuum Marination System – Accelerates seasoning penetration, reduces processing time.

✔ Energy-Efficient Motors – Tailored power output from 0.38 kW to 5.6 kW.

✔ Food-Grade SUS304 Stainless Steel – Corrosion-resistant and easy to clean.

✔ Flexible Speed Options – Roller speeds from 5–13 r/min to suit different meats.

✔ Compact to Large Footprints – From space-saving models (680×370×820 mm) to industrial setups (2545×1420×1870 mm).

Applications

Small Models (10–100L): Ideal for test kitchens, pilot production, and restaurants.

Medium Models (200–800L): Designed for medium-sized meat processors, ready-to-eat factories, and catering suppliers.

Large Models (1000–2000L): Perfect for industrial food plants and frozen meat manufacturers.

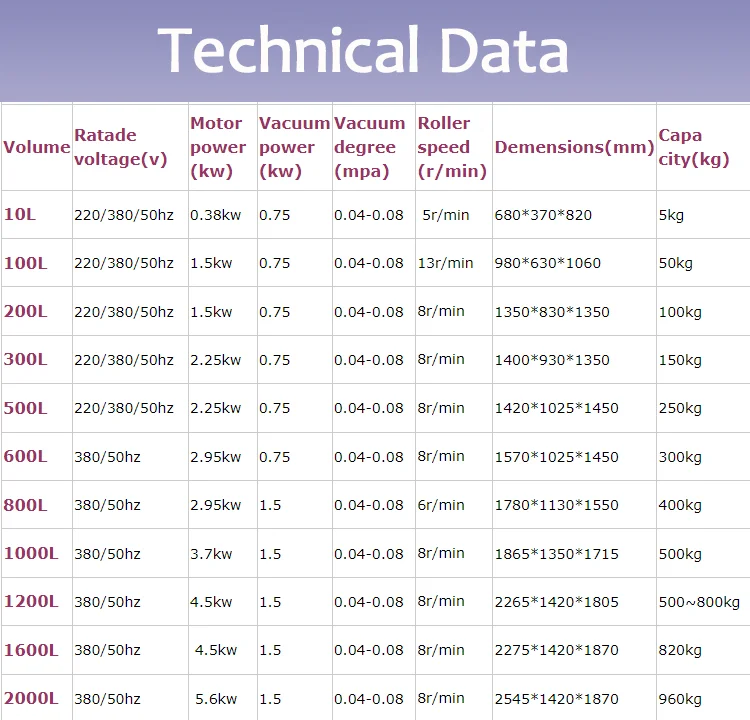

Product Parameters (All Models Available)

| Volume | Voltage | Motor Power | Vacuum Power | Vacuum Degree (Mpa) | Roller Speed (r/min) | Dimensions (mm) | Capacity |

| 10L | 220/380V 50Hz | 0.38 kW | 0.75 kW | 0.04–0.08 | 5 | 680×370×820 | 5 kg |

| 100L | 220/380V 50Hz | 1.5 kW | 0.75 kW | 0.04–0.08 | 13 | 980×630×1060 | 50 kg |

| 200L | 220/380V 50Hz | 1.5 kW | 0.75 kW | 0.04–0.08 | 8 | 1350×830×1350 | 100 kg |

| 300L | 220/380V 50Hz | 2.25 kW | 0.75 kW | 0.04–0.08 | 8 | 1400×930×1350 | 150 kg |

| 500L | 220/380V 50Hz | 2.25 kW | 0.75 kW | 0.04–0.08 | 8 | 1420×1025×1450 | 250 kg |

| 600L | 380V 50Hz | 2.95 kW | 0.75 kW | 0.04–0.08 | 8 | 1570×1025×1450 | 300 kg |

| 800L | 380V 50Hz | 2.95 kW | 1.5 kW | 0.04–0.08 | 6 | 1780×1130×1550 | 400 kg |

| 1000L | 380V 50Hz | 3.7 kW | 1.5 kW | 0.04–0.08 | 8 | 1865×1350×1715 | 500 kg |

| 1200L | 380V 50Hz | 4.5 kW | 1.5 kW | 0.04–0.08 | 8 | 2265×1420×1805 | 500–800 kg |

| 1600L | 380V 50Hz | 4.5 kW | 1.5 kW | 0.04–0.08 | 8 | 2275×1420×1870 | 820 kg |

| 2000L | 380V 50Hz | 5.6 kW | 1.5 kW | 0.04–0.08 | 8 | 2545×1420×1870 | 960 kg |

Customer Benefits

Efficiency for Every Scale: Choose the right size, from lab testing to full-scale production.

Cost Reduction: Faster marination reduces seasoning waste and labor hours.

Quality Consistency: Uniform flavor, tenderness, and juiciness across batches.

Future-Proof Investment: Modular design allows scaling up as production grows.

FAQ

Q1: Which model is best for a small restaurant?

A: The 10L or 100L vacuum meat tumbler is ideal for small-batch marination and recipe testing.

Q2: Can I scale up as my production grows?

A: Yes. We offer models from 10L to 2000L, making it easy to upgrade capacity without changing processing methods.

Q3: Do larger models require special installation?

A: Models above 600L typically require 380V three-phase power and more floor space.

Q4: Does vacuum degree remain consistent across models?

A: Yes, all machines maintain 0.04–0.08 Mpa, ensuring optimal flavor penetration regardless of size.

The Hydraulic Poultry Marinator Series (10L–2000L) is the perfect solution for businesses of all sizes. From restaurants seeking to enhance menu flavors to industrial processors optimizing mass production, this equipment ensures fast marination, consistent product quality, and scalable performance.

Choose the model that fits your operation today—and experience the difference between traditional marination and next-generation vacuum meat tumbling technology.