Professional Grade Commercial Meat Slicer with German Precision Engineering

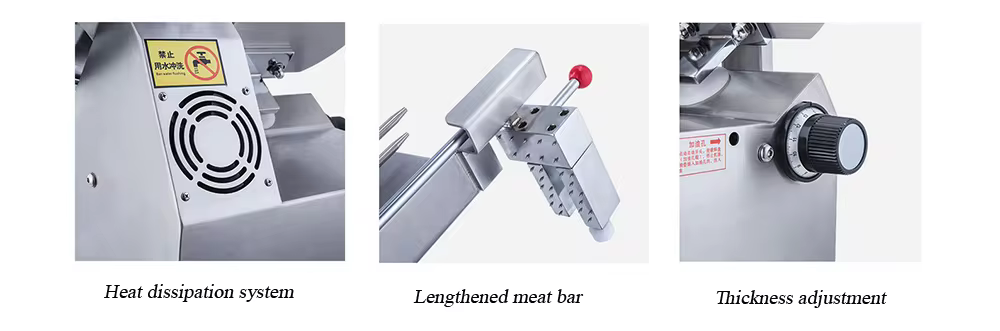

The industrial meat processing equipment features premium SUS304 stainless steel construction. Our commercial meat slicer integrates advanced safety protection systems. The professional beef cutting machine ensures precision slicing control.

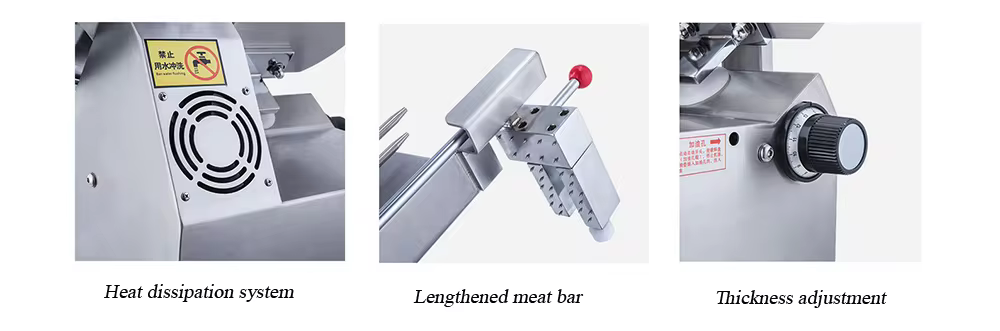

This automatic meat slicer supplier offers innovative feeding mechanisms. Digital controls adjust slice thickness settings. The spiral design enhances cutting efficiency. Our meat cutting equipment maintains consistent slice quality.

The commercial food processing equipment includes automatic reset functions. Industrial butcher equipment provides triple safety protection features. Professional meat processing solutions accommodate both boneless and bone-in products.

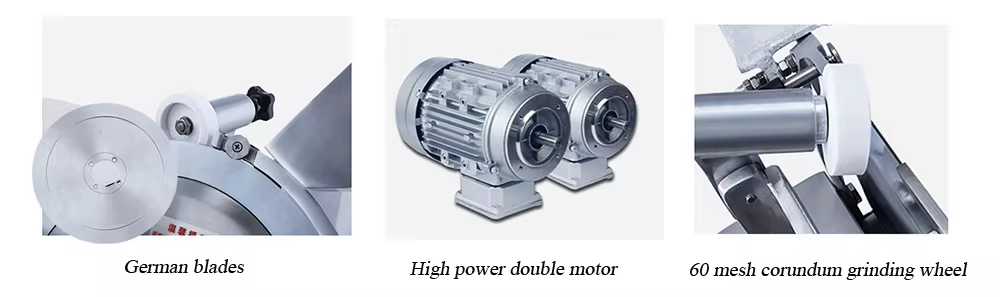

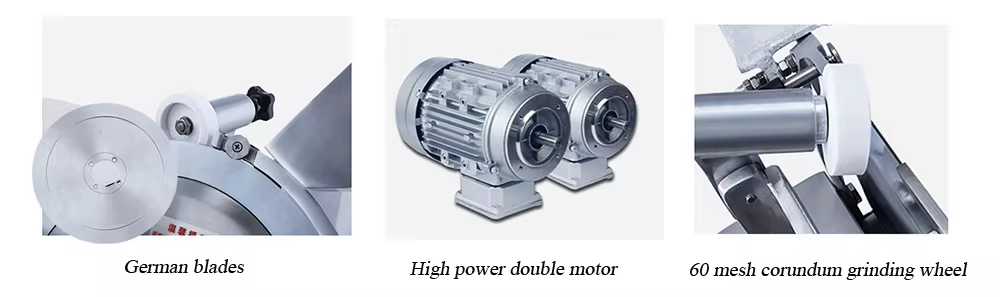

The meat cutting machine price reflects superior German engineering standards. Blade options include straight and serrated cutting edges. Smart feed systems optimize production throughput. Ergonomic design ensures operator comfort.

Product Specifications

| Parameter | Value |

| Model | GS-350 |

| Material | SUS304 Stainless Steel |

| Cutting Capacity | 350mm x 250mm |

| Safety Features | Triple Protection System |

| Control System | Digital Display |

| Blade Options | Straight/Serrated |

| Cutting Thickness | 0.5-25mm Adjustable |

| Power Supply | 380V/50Hz |

| Machine Weight | 380kg |

| Dimension | 1200×800×1150mm |

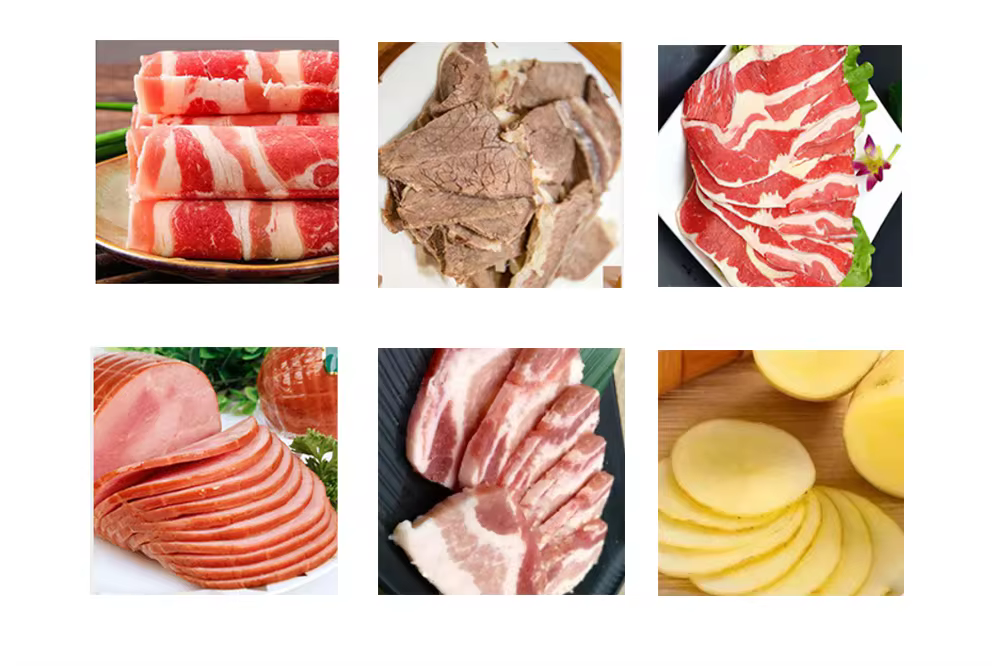

| Applications | Meat Processing Plants, Butcher Shops |

| Certification | CE, ISO9001 |

| Warranty | 12 Months |

Professional Commercial Meat Processing Solutions with German Technology

Advanced Slicing Capabilities

The industrial meat slicer features precision German blade technology. Our commercial beef cutter processes various meat textures. The professional cutting equipment maintains slice consistency. Adjustable thickness settings meet diverse product requirements. The automated feeding system enhances production efficiency.

Innovative Safety Design

Our meat processing machine incorporates comprehensive safety features. The commercial butcher equipment includes emergency shutdown systems. Triple protection mechanisms safeguard operators. Safety interlocks prevent unauthorized access. Real-time monitoring ensures operational security.

Superior Construction Quality

Food-grade stainless steel ensures hygiene standards. The industrial meat cutting machine resists corrosion. Modular design enables quick maintenance access. Heavy-duty components enhance equipment longevity. The commercial food slicer meets international certifications.

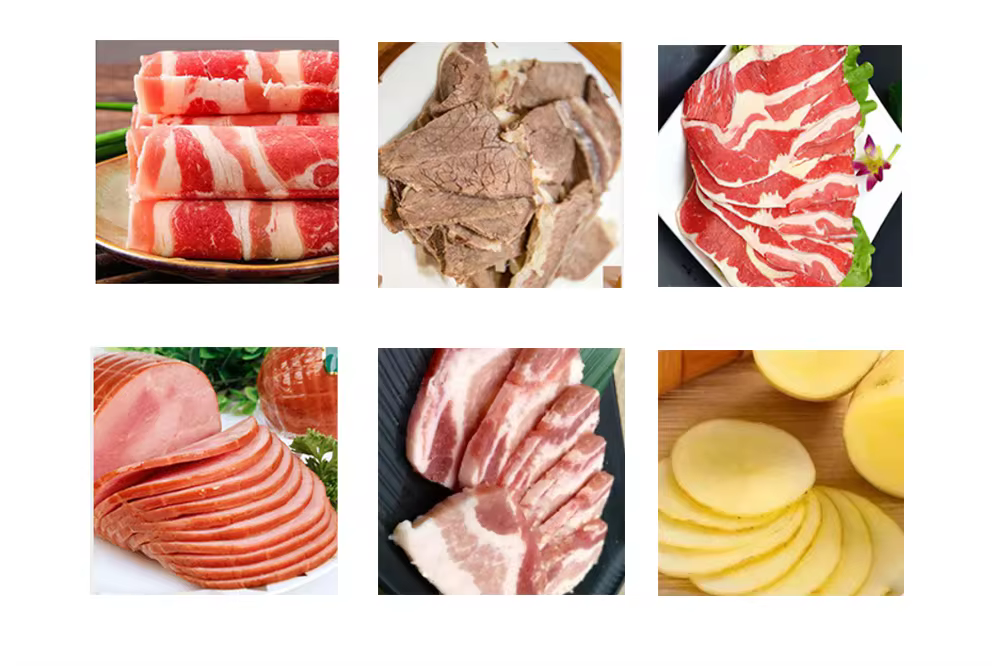

Versatile Processing Solutions

Interchangeable blades handle frozen and fresh meats. The professional meat cutter adapts to various products. Our slicing equipment suits different production scales. Custom cutting programs store multiple settings. The automated system maintains consistent output.

Comprehensive Support Package

We provide complete installation services. Our technical team offers operator training. Regular maintenance programs ensure optimal performance. Spare parts remain readily available. Remote diagnostics reduce downtime costs.

Scope Of Application:

Packing&Delivery:

FAQs

Q1: How do customers switch between different cutting programs on your commercial meat processing equipment?

A1: Our digital control system stores multiple cutting profiles, allowing instant program changes through the touch interface.

Q2: What maintenance is required for the industrial meat slicer's blade system?

A2: Quick-release blade mechanisms enable daily cleaning and scheduled maintenance without specialized tools.

Q3: Can your German-designed beef cutter handle both frozen and fresh meat processing?

A3: Our professional slicer automatically adjusts cutting parameters for optimal results with various meat temperatures.

Q4: Does the commercial butcher equipment include training for our operators?

A4: We provide comprehensive operator training, including safety protocols and production optimization techniques.

Q5: How do you ensure consistent slice thickness in large-scale meat processing?

A5: Digital thickness controls and automated feeding systems maintain precise cutting specifications throughout production.