Overview

Engineered for high-volume vegetable preparation, the Multi Function Vegetable Chopper Machine streamlines pre-processing for potatoes, cassava, carrots, and leafy greens in commercial kitchens and food factories. Combining modular blade systems with adjustable cutting settings, it transforms raw produce into uniform slices, dices, shreds, or gratings (2-20mm) while minimizing waste. The 304 stainless steel construction and quick-clean design ensure compliance with NSF/ANSI 3-A standards, handling up to 800kg/h of root vegetables and soft produce.

Features

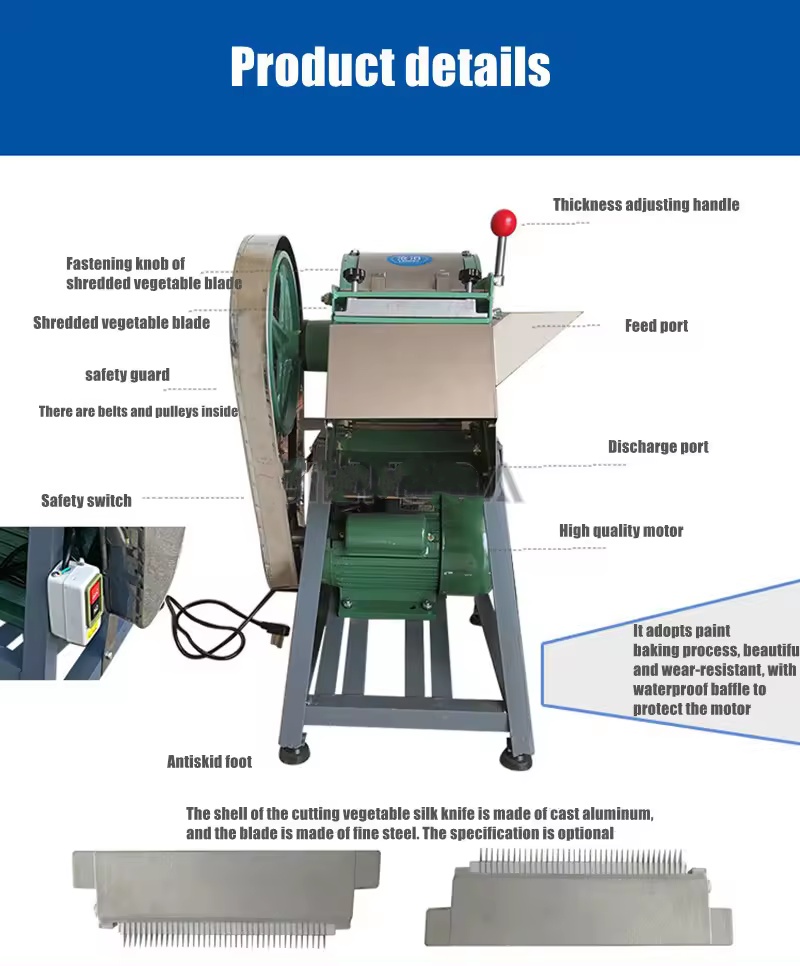

Universal Cutting System: Includes 7 interchangeable blade sets (straight, wavy, cube, Julienne, grater, slicer, and leafy green blades) with tool-free quick-release, converting between cutting styles in <3 minutes.

Dual-Speed Control: Main drum (10-30 RPM) and blade spindle (150-400 RPM) adjustable via frequency converter, optimizing precision for hard roots (potatoes, cassava) and delicate produce (tomatoes, spinach).

Anti-Waste Technology: Angled feed hopper (45°) and precision alignment guides reduce trimming loss to <5%, while the built-in size calibration ring ensures uniform cuts.

Hygienic Design: Fully removable contact parts (blades, drums, hopper) for deep cleaning, with FDA-compliant food-grade lubricants and smooth surface finishes (Ra≤0.8μm).

Intelligent Safety System: Torque-sensing motor reverses direction during jams, while interlock sensors halt operation if the safety guard is opened, reducing operator risk.

Application

Commercial Kitchens: Preps vegetables for soups, salads, and stir-fries in hotels, restaurants, and catering centers, cutting manual labor by 60%.

Snack Manufacturing: Creates potato slices for chips, cassava sticks for fries, and carrot julienne for dehydrated snacks, with optional surface drying attachments.

Juice & Puree Production: Grates ginger, apples, and pears into fine textures for efficient juice extraction, compatible with downstream pulping and sieving systems.

FAQ

Q: Can it process frozen vegetables?

A: Yes, but thaw to 5-10°C first; the heavy-duty blades handle semi-frozen produce (≤-5°C core temperature) with reduced speed (15 RPM).

Q: What is the minimum dice size for potatoes?

A: 2x2mm using the cube blade set; adjustable up to 20x20mm via spacing collars, with digital presets for repeatable cuts.

Q: Is a dedicated electrical phase required?

A: Standard model operates on 3-phase 415V/50Hz, with single-phase 220V/60Hz variants available for small-scale kitchens (output reduced to 500kg/h).