Overview

The Multi Function Vegetable Chopper Machine streamlines pre-processing for fruits and vegetables with interchangeable blades and adjustable settings. Designed for high-volume kitchens and food factories, it slices, dices, and shreds produce into uniform sizes (2-20mm) while minimizing waste. The 304 stainless steel construction and easy-to-clean design make it compliant with NSF/ANSI 3-A standards, handling up to 500kg/h of carrots, potatoes, onions, and leafy greens.

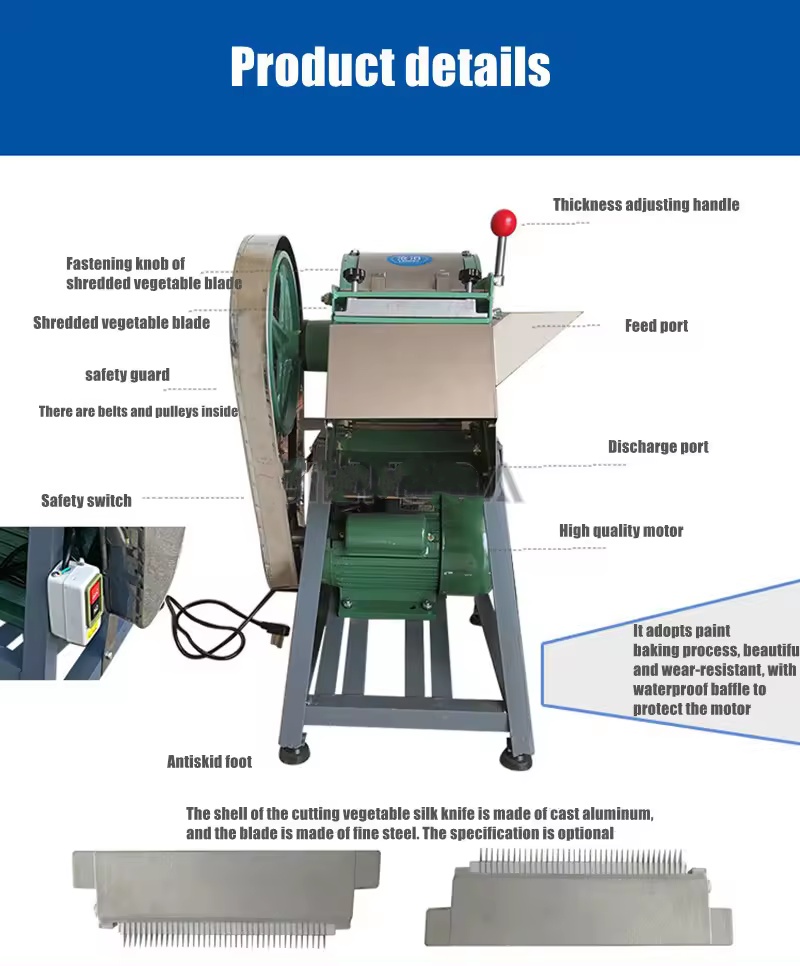

Features

Modular Cutting System: Includes 5 interchangeable blade sets (straight, wavy, grater, cube, Julienne) with quick-release mechanisms, converting between cutting styles in <5 minutes.

Variable Speed Control: 10-30 RPM main drum speed and 200-400 RPM blade rotation via frequency converter, ensuring precise cuts for soft (tomatoes) and hard (beets) produce.

Anti-Jam Technology: Torque-sensing motor automatically reverses direction when overloaded, with safety sensors stopping operation if the hopper lid is opened.

Hygienic Design: Elevated stainless steel legs (300mm height) for floor cleaning, and FDA-compliant food-grade lubricants on moving parts to prevent contamination.

Dust-Free Operation: Optional vacuum attachment (500m³/h) collects vegetable debris, maintaining a clean work environment and reducing airborne allergens.

Application

Commercial Kitchens: Preps vegetables for soups, salads, and stir-fries in hotels, restaurants, and catering companies, reducing manual labor by 70%.

Canning & Freezing Plants: Produces uniform diced onions, sliced carrots, and shredded cabbage for IQF (Individually Quick Frozen) processing.

Juice & Puree Production: Grates ginger, apples, and pears into fine textures for efficient juice extraction, with optional pulping attachments.

Snack Manufacturing: Creates uniform potato slices for chips, carrot sticks for snacks, and vegetable strips for dehydrated products.

FAQ

Q: Can it handle leafy greens (e.g., lettuce, spinach)?

A: Yes, using the soft-leaf blade set with reduced speed to prevent bruising, producing consistent shreds for salads and wraps.

Q: What is the minimum dice size?

A: 2x2mm for hard vegetables (carrots, potatoes), adjustable up to 20x20mm via blade spacing collars.

Q: Is a water supply required for cleaning?

A: No, the detachable blade unit and drum can be cleaned with a high-pressure water gun or manually, with all components dishwasher-safe (except electrical parts).