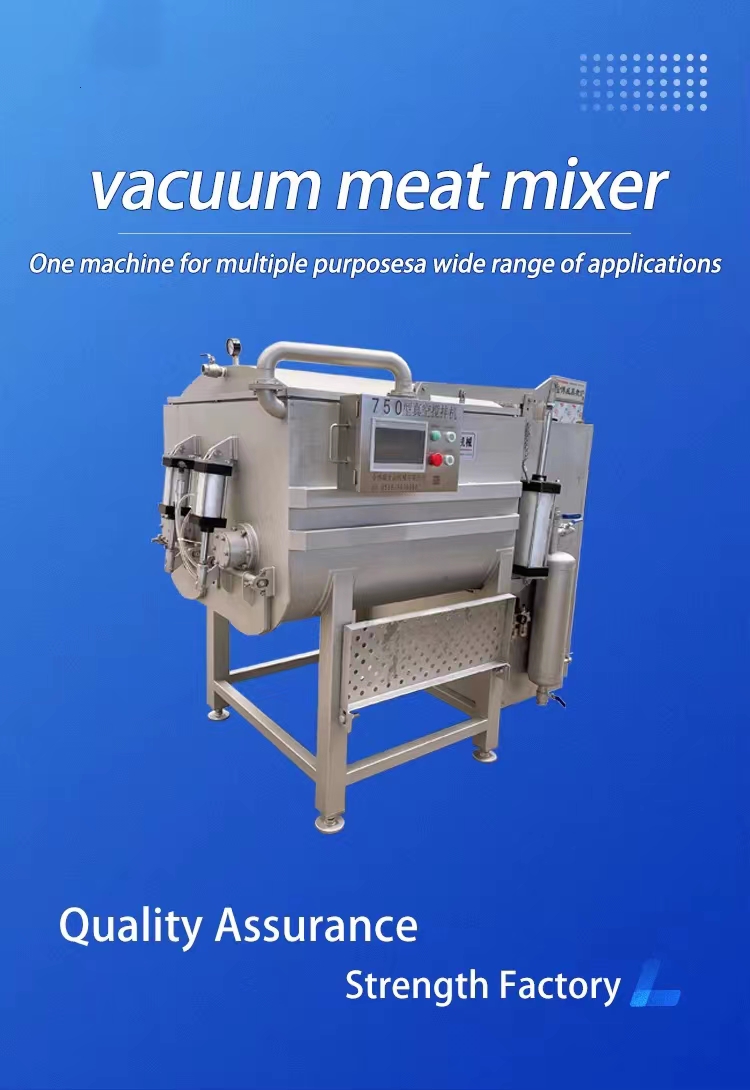

Commercial Automatic Vacuum Meat Mixer 304 Stainless Steel Electric Vegetable Stuffing Mixing Machine

Professional Commercial Vacuum Meat Mixing and Stuffing Equipment

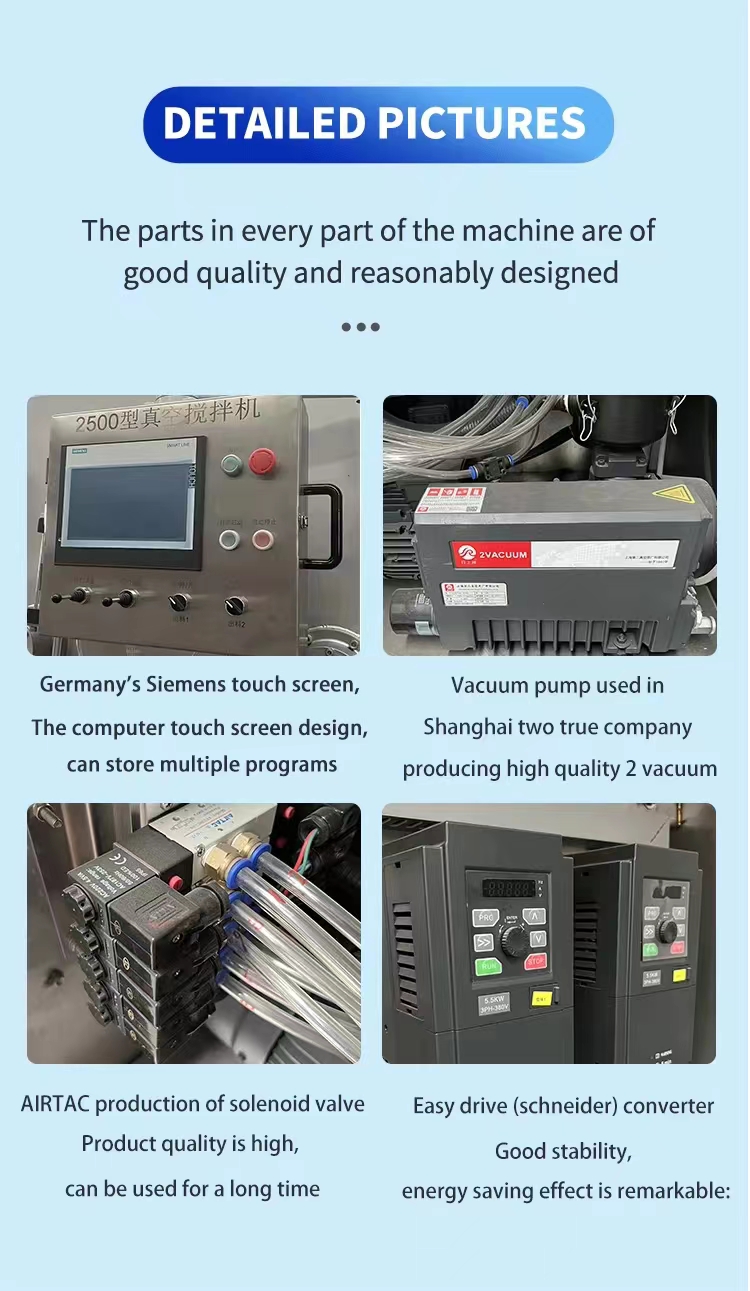

The industrial vacuum meat mixer features premium components and intelligent design. Our commercial stuffing machine integrates Siemens touchscreen controls. The professional food mixing equipment stores multiple processing programs.

This automatic meat processing system incorporates high-performance vacuum technology. The industrial food mixer supplier ensures consistent mixing quality. Two-stage vacuum pumps enhance product texture. Advanced electromagnetic valves maintain operational precision.

The commercial meat mixer manufacturer implements Schneider frequency controls. Energy-efficient design reduces operational costs. The vacuum food processor equipment delivers reliable performance. Quality components ensure long-term durability.

Our meat mixing machine factory conducts comprehensive quality testing. The professional stuffing equipment meets international standards. Efficient delivery systems support global distribution.

| Parameter | Value |

| Model | VM-2500 |

| Mixing Capacity | 2500L |

| Control System | Siemens Touch Screen |

| Vacuum Pump | Two-Stage System |

| Power Supply | 380V/50Hz |

| Mixing Speed | Variable Speed Control |

| Material | SUS304 Stainless Steel |

| Program Storage | Multiple Programs |

| Valve System | Professional Grade |

| Drive System | Schneider Inverter |

| Safety Features | Multiple Protection |

| Certification | CE, ISO9001 |

| Application | Food Processing Industry |

| Warranty | 12 Months |

Production Details

Professional Vacuum Meat Mixing Equipment with Advanced Processing Technology

Superior Mixing Performance

The commercial meat mixer delivers uniform ingredient distribution. Our vacuum mixing technology eliminates air pockets. The industrial food processor features cross-wheel blade design. Precision gap settings ensure thorough mixing results. The automatic stuffing machine maintains consistent product quality.

Intelligent Control Systems

Digital interface monitors all processing parameters. The professional meat mixer offers programmable recipes. Temperature control systems protect product quality. Our industrial mixing equipment enables real-time adjustments. Smart loading mechanisms optimize production capacity.

Hygienic Design Features

Food-grade stainless steel construction ensures safety standards. The commercial stuffing machine includes quick-clean components. Triple-seal protection prevents contamination. Our vacuum processing equipment meets international certifications. Easy-access design simplifies maintenance procedures.

Versatile Applications

The industrial meat processor handles various product types. Adjustable mixing speeds suit different ingredients. Our vacuum stuffing equipment processes both wet and dry materials. Custom programming meets specific production requirements. The professional mixing system integrates with existing lines.

Safety and Efficiency

Automated discharge reduces labor needs. Multiple safety features protect operators. Energy-efficient design lowers operational costs. Remote monitoring enables process optimization. Our equipment includes comprehensive safety interlocks.

End Product

Product Packaging

FAQs

Q1: How does your vacuum mixing system improve meat product quality?

A1: Our vacuum technology removes air pockets, enhancing texture and extending shelf life while maintaining product consistency.

Q2: Can the commercial mixer handle both wet and dry ingredients simultaneously?

A2: The cross-wheel blade design efficiently combines various ingredients while maintaining optimal moisture distribution.

Q3: What cleaning procedures ensure food safety in your stuffing equipment?

A3: Quick-release components and triple-seal design enable thorough sanitization, meeting international food safety standards.

Q4: Do you offer customization for specific production requirements?

A4: We customize mixing programs, capacity options, and integration solutions to match your processing needs.

Q5: How does the automatic discharge system improve production efficiency?

A5: Smart discharge mechanisms reduce labor needs while maintaining precise portion control throughout production cycles.