Fully Automatic French Fry/Potato Chip/Banana Chip Frying Assembly Line

Professional Automatic Potato and Banana Chips Production Line with Deep Frying Technology

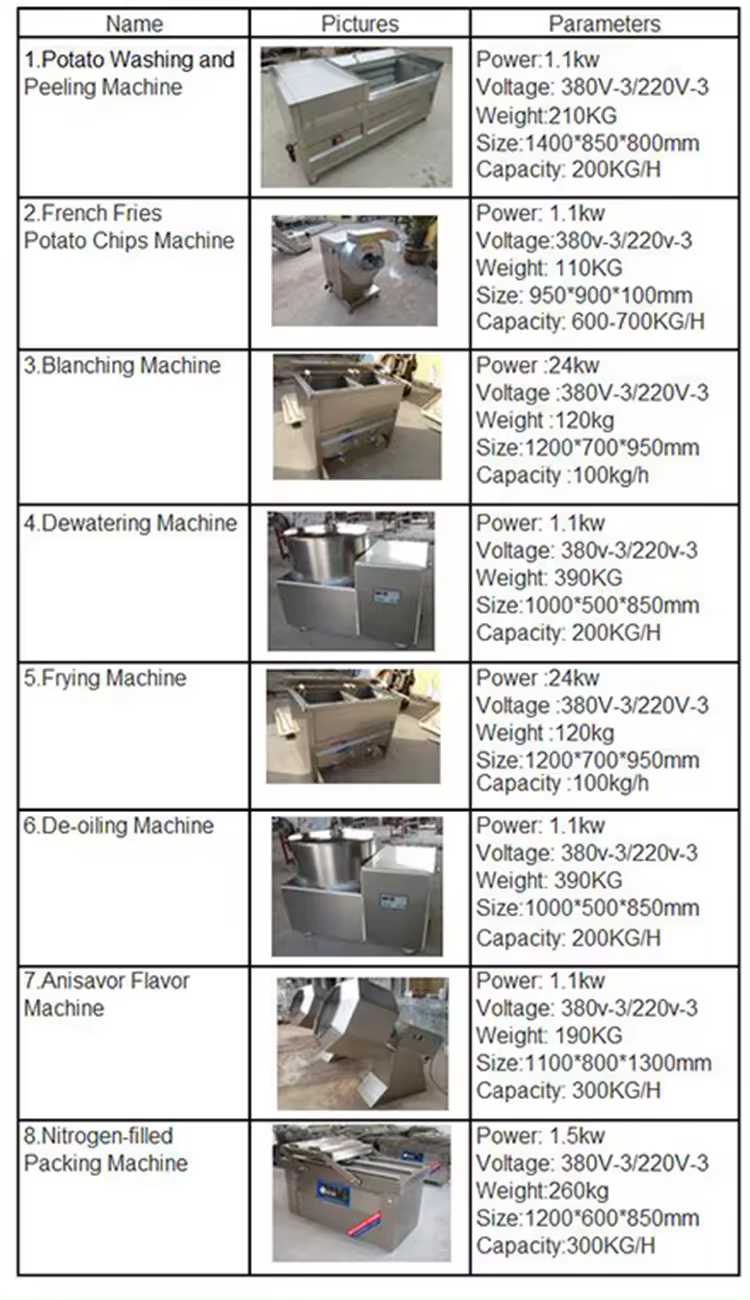

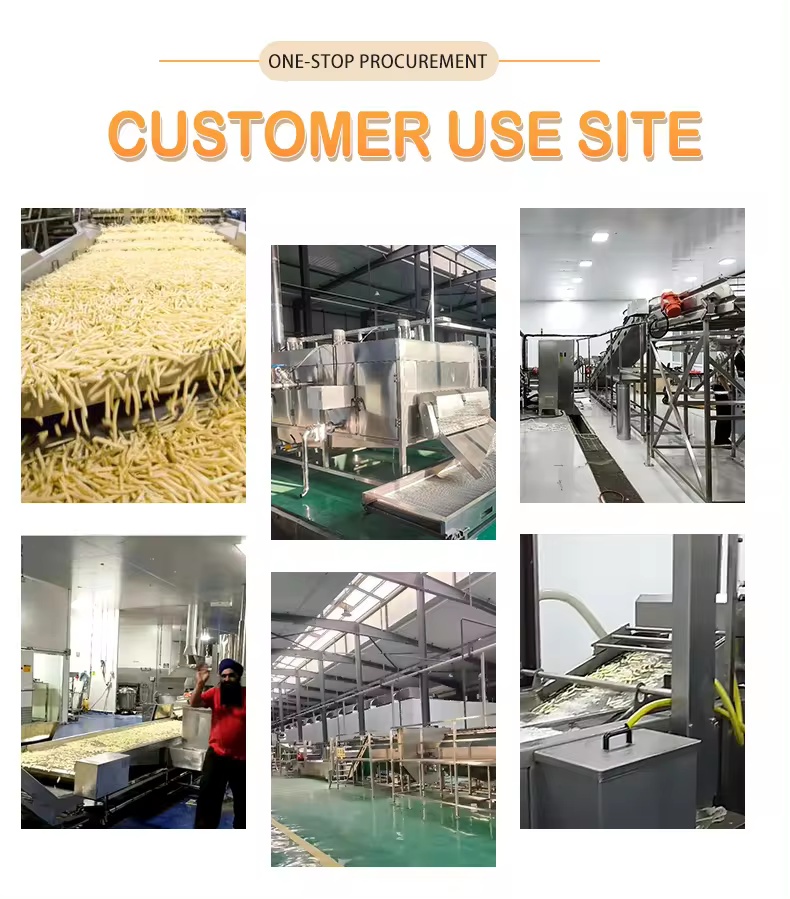

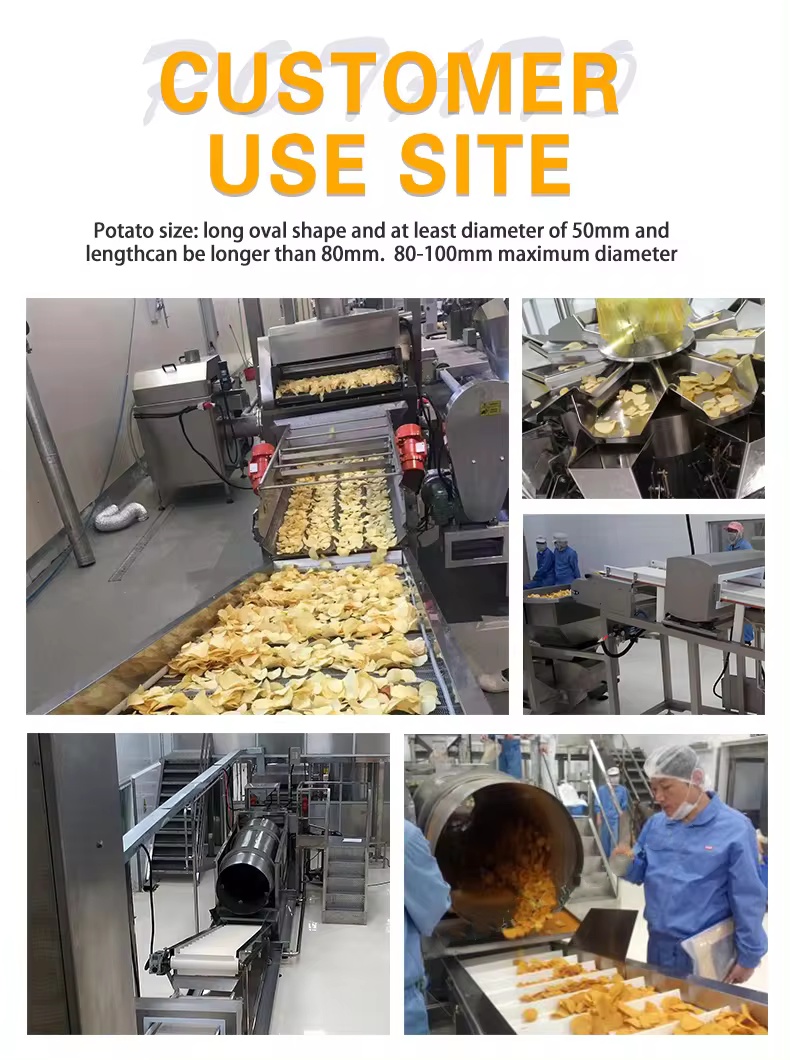

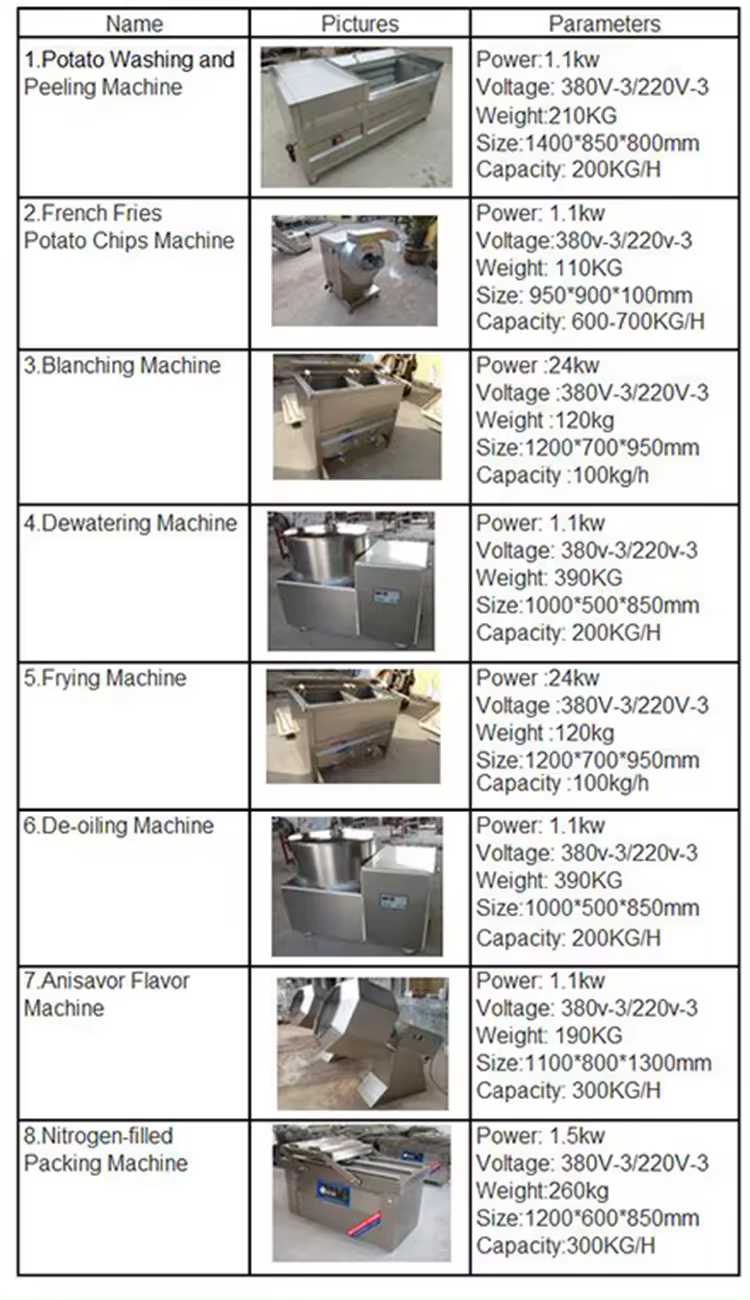

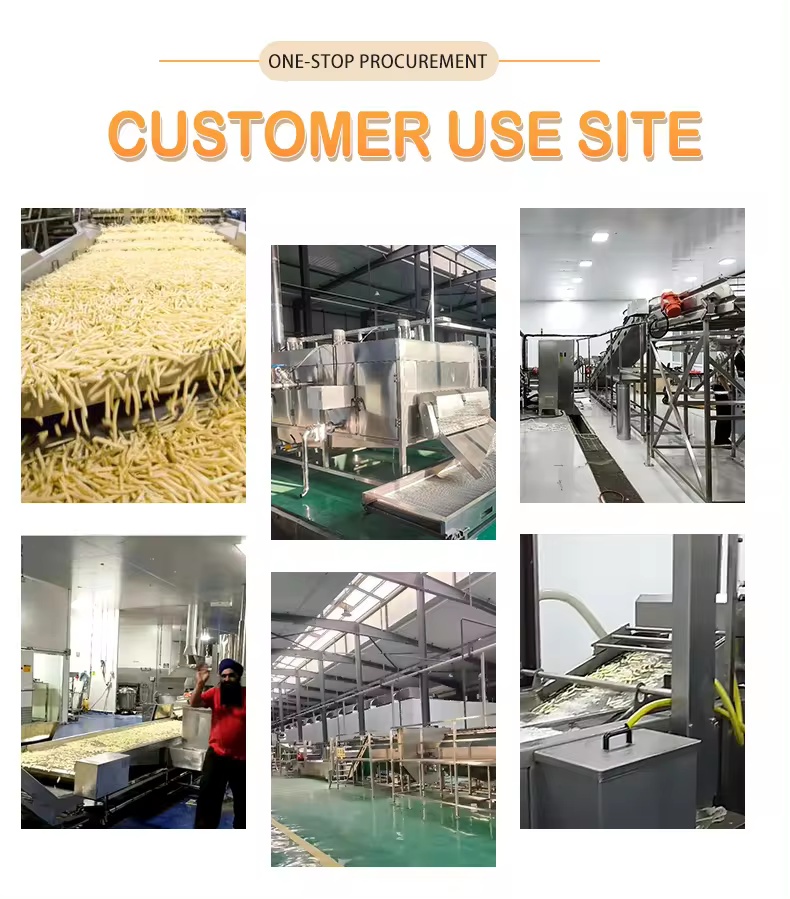

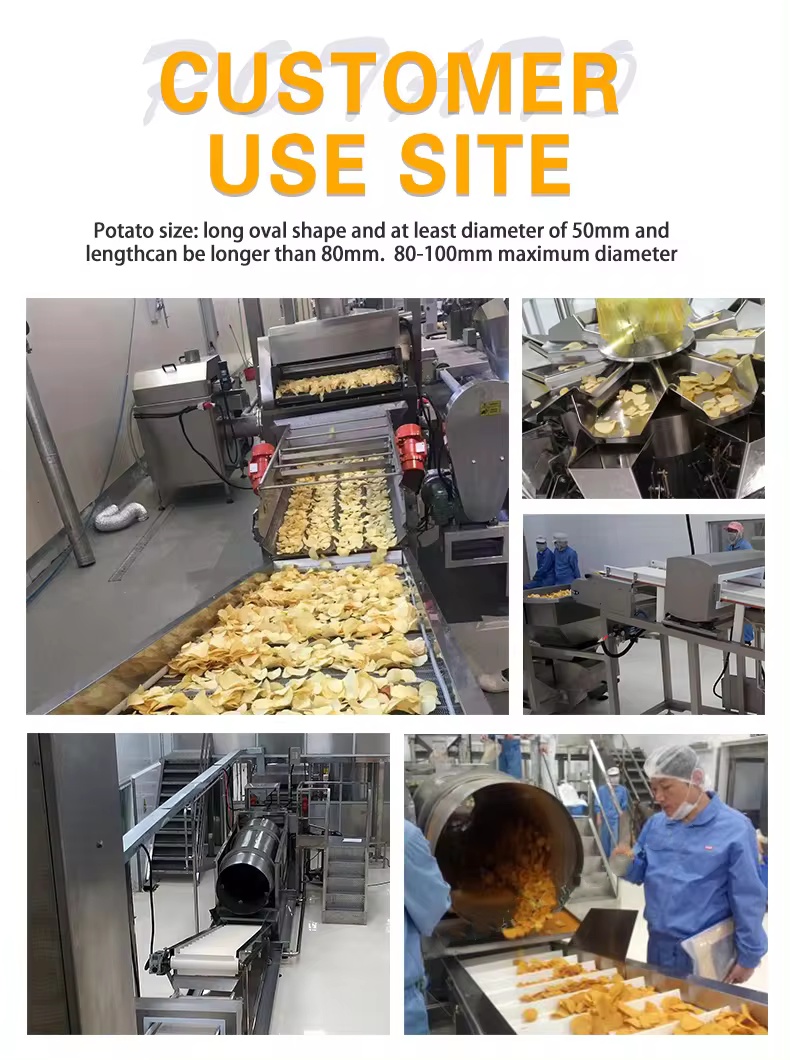

The industrial frying line manufacturer delivers complete snack processing solutions. This automatic potato chips production line integrates advanced processing technologies. Commercial french fry equipment ensures consistent product quality. The continuous frying system supplier optimizes production efficiency.

Our food processing line equipment features stainless steel construction. The automated snack production line includes washing, peeling, and slicing units. Industrial deep fryer machine maintains precise temperature control. Each processing stage guarantees product consistency.

The banana chips processing machine adapts to multiple products. Fresh potatoes transform into crispy snacks through automated stages. Seasoning systems ensure uniform flavor distribution. Customized solutions meet specific production requirements.

This compact production line suits small-scale operations. Quality control systems monitor each processing step. Energy-efficient design reduces operational costs. Professional installation and training services included.

| Name | French Fries Potato Chips Production Line |

| Model | 100TP |

| Capacity | 100kg/h |

| Materials | Nice Quality 304 Stainless Steel |

| Raw Materials | Fresh Potatoes |

| Final Products | French Fries or Potato Chips |

| Function | To Produce French Fries or Potato Chips |

| Application | Wastern Restaurant,Tea cafe,Beverage Shop,Snack Food Plant,Seasoning plant |

| Warranty | One year |

| Customize | Also we can do Customize Service according to customers requirements. |

Key Features of Professional Food Frying Line and Processing Equipment

Production Efficiency

Industrial deep fryer machine delivers optimal output with minimal energy consumption

Continuous frying system processes multiple products simultaneously

Smart temperature control maintains consistent product quality

Automated feeding system reduces labor requirements

Production capacity matches small to medium business needs

Customization Options

We customize automatic potato chips production line to match your specifications

Modular design allows flexible configuration adjustments

Processing parameters adapt to different product requirements

Equipment layout optimizes your available space

Installation support ensures proper setup

Quality Assurance

Advanced seasoning system prevents product breakage

Potato chip assembly line maintains uniform cooking standards

Precise oil temperature control ensures product consistency

Automatic moisture control systems protect product quality

Food-grade materials meet international standards

Technical Support

Our engineering team provides complete solution design

Expert consultation for production line optimization

Regular technical updates enhance equipment performance

Remote troubleshooting reduces downtime

Comprehensive operator training included

Safety Features

French fry assembly line includes emergency stop systems

Oil filtration maintains product safety standards

Temperature monitoring prevents overheating

Safety guards protect operators

Easy-clean design ensures hygiene standards

FAQs

Q1: Can your industrial frying line process different snack products besides potato chips?

A1: Our versatile frying assembly line handles potatoes, bananas, and other root vegetables with customized processing settings.

Q2: What oil filtration system does the automatic chip production line use?

A2: We incorporate continuous oil circulation and filtration technology to maintain product quality and extend oil life.

Q3: How do you ensure consistent seasoning distribution in the snack processing line?

A3: Our automated seasoning system provides uniform coating while protecting product integrity during the finishing process.

Q4: What expertise levels do operators need for the french fry production equipment?

A4: Our user-friendly control system requires minimal training, and we provide comprehensive operational guidance.

Q5: Do you offer customization for small-scale production facilities?

A5: We design compact frying solutions to fit your space requirements while maintaining optimal production efficiency.