Small-Scale French Fries and Potato Chips Production Line for Food Processing Industry

Advanced Processing Technology

The 100TPD potato chips production line manufacturer delivers efficient snack processing solutions. Each industrial french fries machine integrates automated washing systems. The commercial potato processing equipment maintains strict quality control. Our food grade processing equipment ensures hygienic production standards.

Production Capabilities

The french fries production line supplier offers 100kg hourly output capacity. This potato chips manufacturing plant features precision cutting technology. The automated potato processing system guarantees uniform thickness. Professional industrial potato chip fryer maintains optimal temperature control.

Quality Construction Features

Premium SUS304 stainless steel ensures durability. The commercial french fry maker includes safety protection systems. Every potato chip production equipment undergoes strict testing. Enhanced automation reduces labor requirements significantly.

Custom Solutions and Support

Our potato processing line manufacturer provides customization options. The industrial food processing equipment adapts to space requirements. Professional installation team ensures proper setup. Complete technical support throughout operation lifecycle.

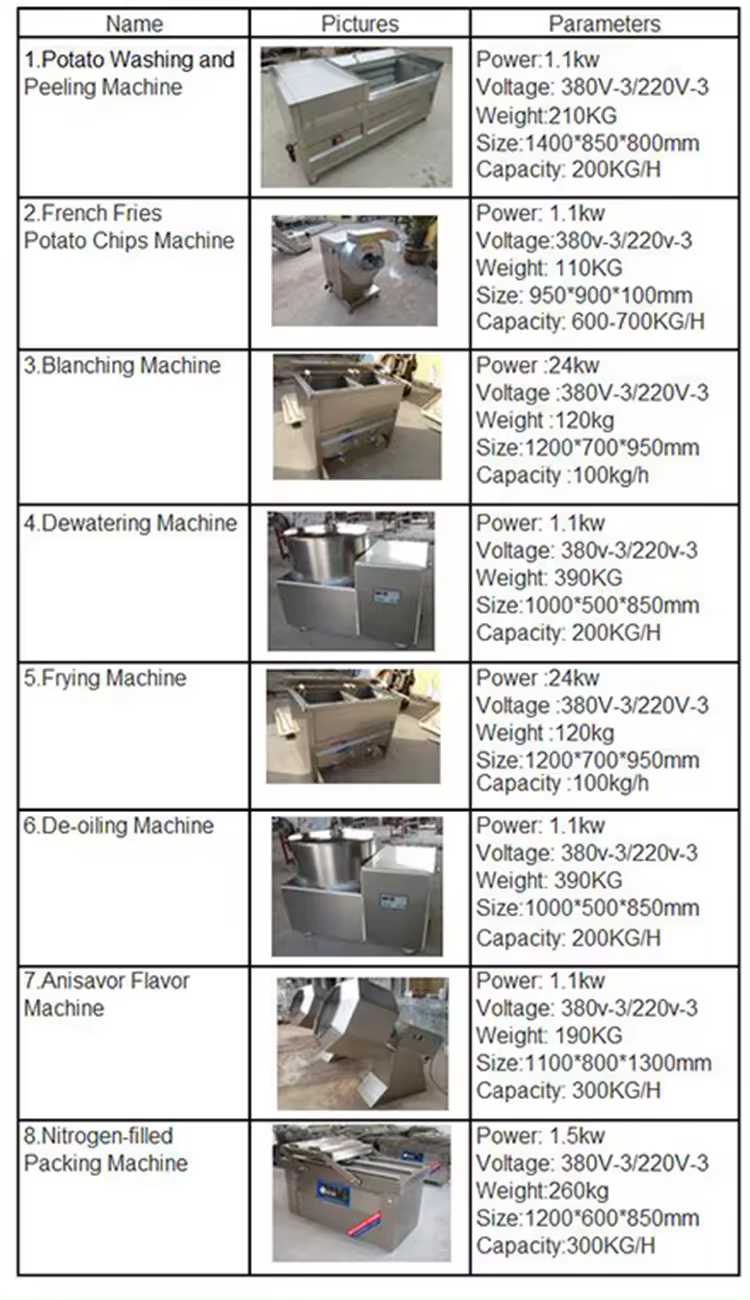

Product Details

Name | French Fries Potato Chips Production Line |

Model | 100TP |

Capacity | 100kg/h |

Materials | Nice Quality 304 Stainless Steel |

Raw Materials | Fresh Potatoes |

Final Products | French Fries or Potato Chips |

Function | To Produce French Fries or Potato Chips |

Application | Wastern Restaurant,Tea cafe,Beverage Shop,Snack Food Plant,Seasoning plant |

Warranty | One year |

Customize | Also we can do Customize Service according to customers requirements. |

Key Features of Custom French Fries and Potato Chips Production Line Equipment

Production Benefits

Complete potato chips production line customization meets specific factory layouts and requirements

Industrial french fries machine processes 100kg per hour with 30% less energy consumption

Automated potato processing system maintains consistent output quality

Commercial food processing equipment suits small to medium enterprises

Compact design maximizes space utilization in limited areas

Technical Advantages

The french fries production line integrates PLC control systems for precise operation

Professional potato chip making machine includes automatic seasoning distribution

Advanced cutting technology ensures uniform chip thickness

Industrial potato fryer maintains optimal oil temperature

Continuous production cycle reduces labor costs

Quality Assurance

Food grade stainless steel construction ensures hygiene standards

Expert technical team provides installation and maintenance support

Each industrial potato processor undergoes strict quality testing

Built-in safety features protect operators during production

Regular software updates improve system performance

Value-Added Services

24/7 technical consultation for potato processing equipment operation

Comprehensive operator training included

Custom production line design service available

Spare parts inventory ensures minimal downtime

Remote troubleshooting support reduces maintenance costs

FAQs

Q1: What is the minimum space requirement for installing a small-scale french fries production line?

A1: Our compact potato processing equipment needs 100-150 square meters, depending on your customized layout requirements.

Q2: How long does it take to train operators for the potato chips manufacturing system?

A2: We provide comprehensive training within 3-5 days, ensuring your team masters all production operations.

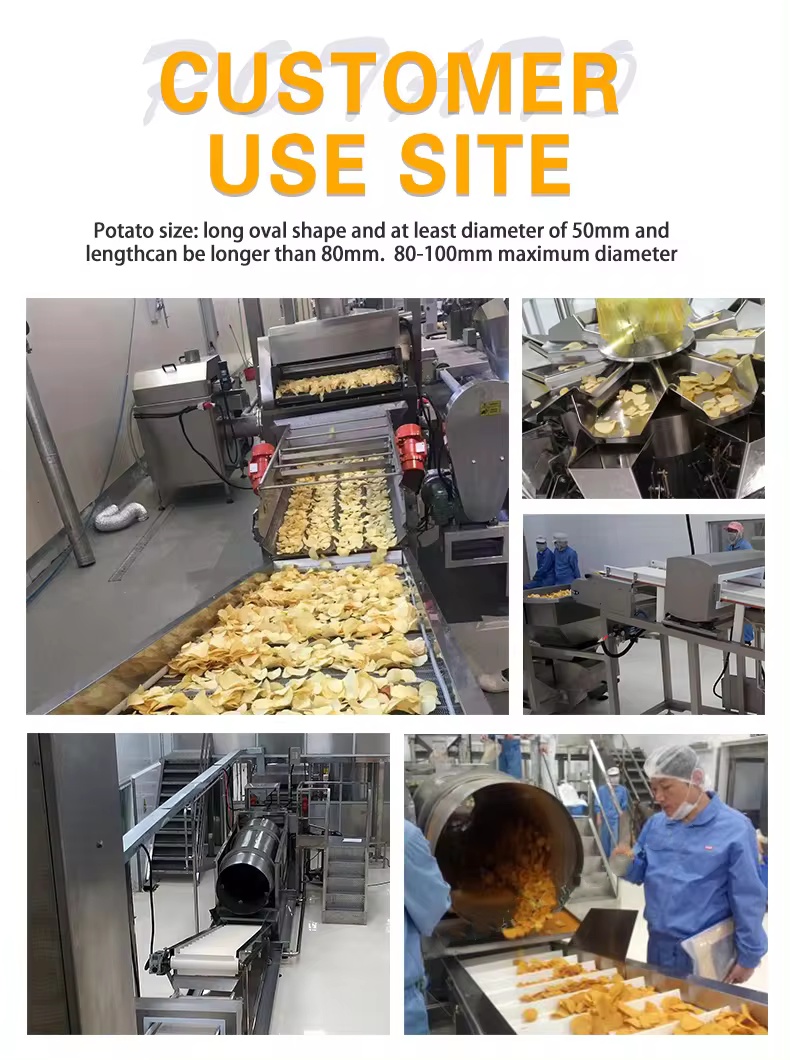

Q3: Can the industrial french fries machine process different potato varieties?

A3: Our commercial potato processor adapts to various potato types through customizable cutting and frying settings.

Q4: What after-sales support do you offer for the french fries processing equipment?

A4: We provide 24/7 technical support, remote troubleshooting, and regular maintenance visits throughout warranty period.

Q5: Is the potato chips production line equipment certified for international food safety standards?

A5: Our processing equipment meets CE, ISO, and HACCP certifications for global food safety requirements.