content is empty!

| Size: | |

|---|---|

| Material: | |

| Availability: | |

| Quantity: | |

HYL OEM

HUIYILAI

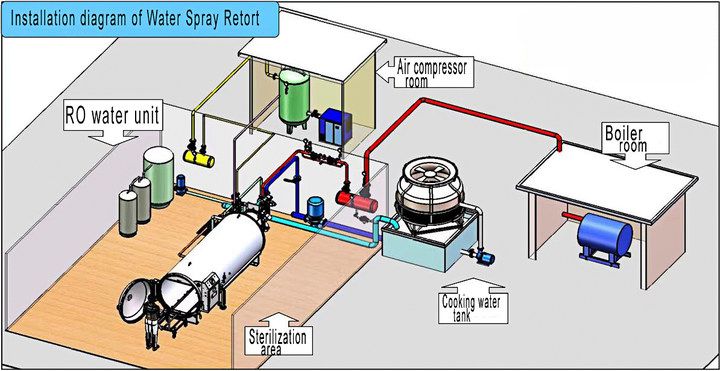

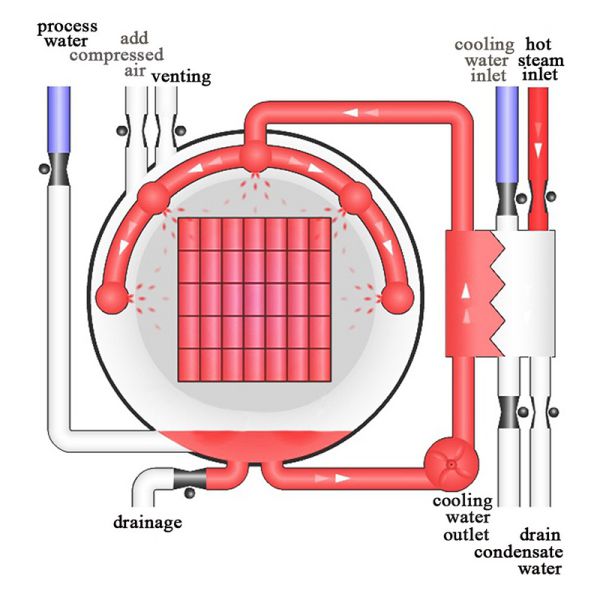

The sterilizer's innovative design ensures precise temperature control and offers the option of a rotating type for larger containers. It is compatible with various packaging materials, including glass jars, tinplate cans, aluminum cans, PP bottles, HDPE bottles, aluminum foil bags, transparent bags, vacuum bags, and more. The water shower counter maintains consistent temperature and pressure, ensuring uniform disinfection and minimizing package distortion. With its high level of automation, the batch counter is user-friendly and reduces the need for manual intervention, enhancing operational efficiency and preserving package integrity.

Glass containers: glass jars

Metal containers: tinplate cans, aluminum cans

Plastic containers: PP bottles, HDPE bottles

Soft bag packaging: aluminum foil bags, transparent bags, vacuum bags

Vacuum bags for cooking, etc.

The water shower counter uses a continuous control of temperature and strain to guarantee even conveyance of intensity and stable tension inside the vessel. This outcomes in a predictable disinfection impact, diminishing bundle twisting and harm while saving bundle trustworthiness. The elevated degree of robotization makes working the clump counter simple and decreases work force.

The water shower counter is an essential component in ensuring the consistent and reliable disinfection process. By utilizing a continuous control of temperature and strain, it maintains a stable tension inside the vessel, resulting in an even distribution of intensity. This not only minimizes package distortion and damage but also preserves the integrity of the packages. The high level of automation streamlines the operation of the batch counter, making it user-friendly and reducing the need for extensive manual labor. Overall, the water shower counter plays a crucial role in maintaining efficiency and effectiveness in the disinfection process, ensuring optimal results with minimal effort.

Different showering strategies can be decided to suit various sorts of bundling, including adaptable packs, inflexible compartments, plastic jugs, and glass holders.

By switching the water flow direction in the sterilization tank, uniform water flow to all directions is achieved.

The ideal system to disperse the water flow to the center of each product tray provides uniform sterilization.

By preparing hot water in advance and the heat sterilizing from the high temperature, enable high temperature sterilization in a short time.

In case of the stationary type, high viscosity foods using large size cans and commercial pouches are difficult to heat sterilize to the center in a short time. By stirring with rotational motion, high viscosity food can be uniformly heated to the center in a short time, and efficiently sterilized.

For the air-containing container, processing with optimal conditions including the preparation temperature of the hot water tank, processing temperature, temperature curve and pressure curve (air-containing container processing system).

Adopting AMMU (Pattern setting instrument) to set and register the planned sterilization conditions for food sterilization (HACCP-compatible). The ideal system to prevent the mistake of the setting operation by calling up the best sterilization condition by the pattern card by one touch, it is possible to correspond from one sterilizer unit to the unmanned operation in the factory.

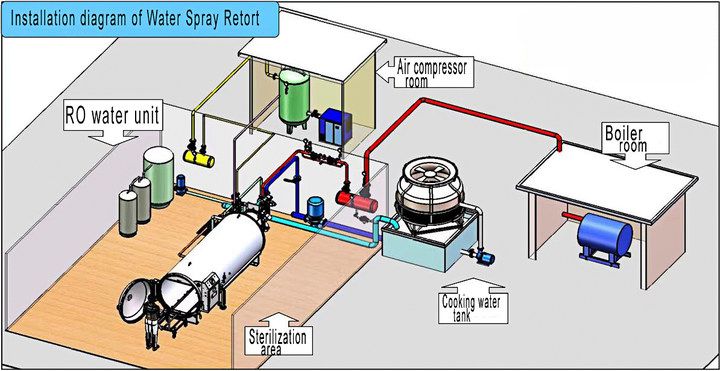

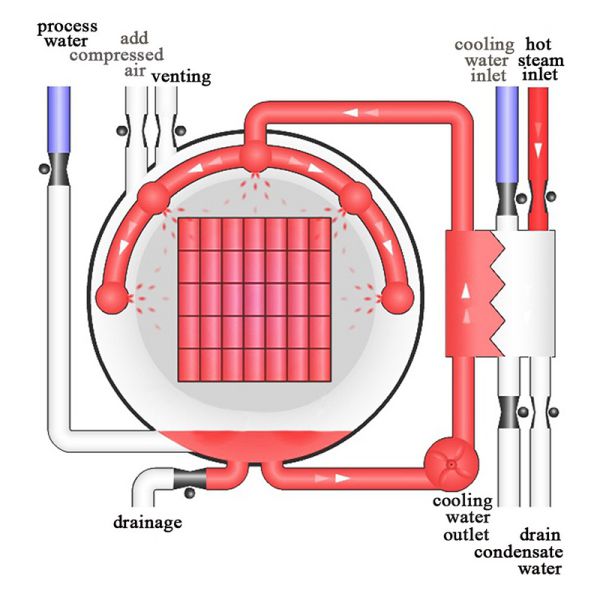

The sterilizer's innovative design ensures precise temperature control and offers the option of a rotating type for larger containers. It is compatible with various packaging materials, including glass jars, tinplate cans, aluminum cans, PP bottles, HDPE bottles, aluminum foil bags, transparent bags, vacuum bags, and more. The water shower counter maintains consistent temperature and pressure, ensuring uniform disinfection and minimizing package distortion. With its high level of automation, the batch counter is user-friendly and reduces the need for manual intervention, enhancing operational efficiency and preserving package integrity.

Glass containers: glass jars

Metal containers: tinplate cans, aluminum cans

Plastic containers: PP bottles, HDPE bottles

Soft bag packaging: aluminum foil bags, transparent bags, vacuum bags

Vacuum bags for cooking, etc.

The water shower counter uses a continuous control of temperature and strain to guarantee even conveyance of intensity and stable tension inside the vessel. This outcomes in a predictable disinfection impact, diminishing bundle twisting and harm while saving bundle trustworthiness. The elevated degree of robotization makes working the clump counter simple and decreases work force.

The water shower counter is an essential component in ensuring the consistent and reliable disinfection process. By utilizing a continuous control of temperature and strain, it maintains a stable tension inside the vessel, resulting in an even distribution of intensity. This not only minimizes package distortion and damage but also preserves the integrity of the packages. The high level of automation streamlines the operation of the batch counter, making it user-friendly and reducing the need for extensive manual labor. Overall, the water shower counter plays a crucial role in maintaining efficiency and effectiveness in the disinfection process, ensuring optimal results with minimal effort.

Different showering strategies can be decided to suit various sorts of bundling, including adaptable packs, inflexible compartments, plastic jugs, and glass holders.

By switching the water flow direction in the sterilization tank, uniform water flow to all directions is achieved.

The ideal system to disperse the water flow to the center of each product tray provides uniform sterilization.

By preparing hot water in advance and the heat sterilizing from the high temperature, enable high temperature sterilization in a short time.

In case of the stationary type, high viscosity foods using large size cans and commercial pouches are difficult to heat sterilize to the center in a short time. By stirring with rotational motion, high viscosity food can be uniformly heated to the center in a short time, and efficiently sterilized.

For the air-containing container, processing with optimal conditions including the preparation temperature of the hot water tank, processing temperature, temperature curve and pressure curve (air-containing container processing system).

Adopting AMMU (Pattern setting instrument) to set and register the planned sterilization conditions for food sterilization (HACCP-compatible). The ideal system to prevent the mistake of the setting operation by calling up the best sterilization condition by the pattern card by one touch, it is possible to correspond from one sterilizer unit to the unmanned operation in the factory.