The Automatic Steam Type Retort Autoclave Sterilizer Machine is a state-of-the-art solution for sterilizing food products in various packaging types. It offers versatile, high-performance sterilization for a wide range of food containers, including glass jars, metal cans, plastic bottles, and vacuum pouches. With its advanced water spray mechanism and optional rotating features, this sterilizer ensures efficient and consistent sterilization, reducing temperature variation and maintaining product integrity.

Ideal for large-scale food processing operations, the Automatic Steam Type Retort provides a highly automated process, reducing the labor intensity involved in traditional sterilization methods. Whether you're sterilizing high-viscosity foods in large cans or flexible packaging materials, this machine ensures optimal sterilization conditions, ensuring food safety while preserving flavor and texture.

Key Features

Uniform Water Flow Dispersion: The retort utilizes an advanced water flow direction switching system that ensures even distribution of water to all parts of the sterilization chamber. This leads to consistent sterilization across all product trays.

High-Temperature and Rapid Processing: Pre-heated water facilitates high-temperature sterilization, reducing the overall processing time for effective sterilization in a shorter period.

Rotating Option for Large Cans and Commercial Pouches: The optional rotating type allows for the sterilization of large size cans and commercial pouches, ensuring even heat distribution, particularly for high-viscosity foods that require more time to reach the center.

Optimal Conditions for Air-Containing Containers: For air-containing packaging, the machine optimizes sterilization conditions, including temperature and pressure profiles, to ensure proper sterilization for containers like plastic bottles and cans.

Advanced Control Technology: The machine is equipped with AMMU (Pattern Setting Instrument) for pre-setting sterilization parameters, offering HACCP-compatible features for seamless operation and reduced operator error. It supports automation for unmanned operation in large-scale factories.

Energy Efficiency: Compared to conventional steam sterilizers, the steam-air retort uses approximately 25% less steam, making it more energy-efficient. The use of sterile water for steam production and direct heat transfer eliminates the need for hot water heating, improving efficiency.

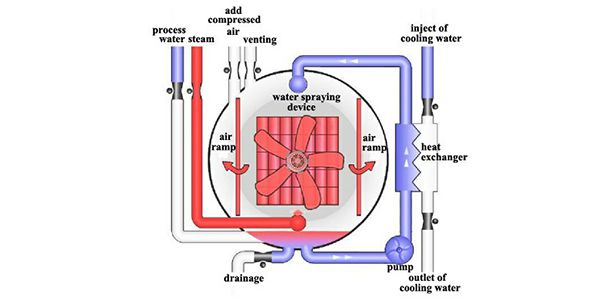

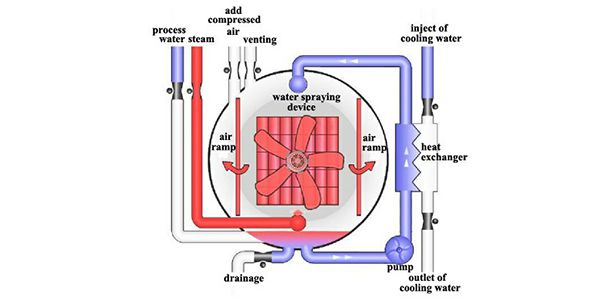

Working Principle

Sterilization Process

The sterilization begins with the introduction of steam into the retort. A high-flow axial fan circulates the steam and air within the retort chamber at high speeds, ensuring uniform temperature distribution throughout. Gradually, the temperature inside the retort is increased to the desired sterilization level. Pressure is adjusted using a pressure-regulating valve, and excess steam is released via an exhaust valve.

Cooling Process

Once sterilization is complete, the cooling stage begins. Cooling water is injected into the system and circulated through a heat exchanger, gradually lowering the temperature of the sterilizing water until it reaches the desired level. This step ensures the product is adequately cooled to maintain its quality.

Blowdown and Pressure Adjustment

The blowdown valve expels the remaining sterilization water, and the exhaust valve helps reduce pressure within the retort. These adjustments ensure the safe operation of the retort and prevent damage to the packaged products.

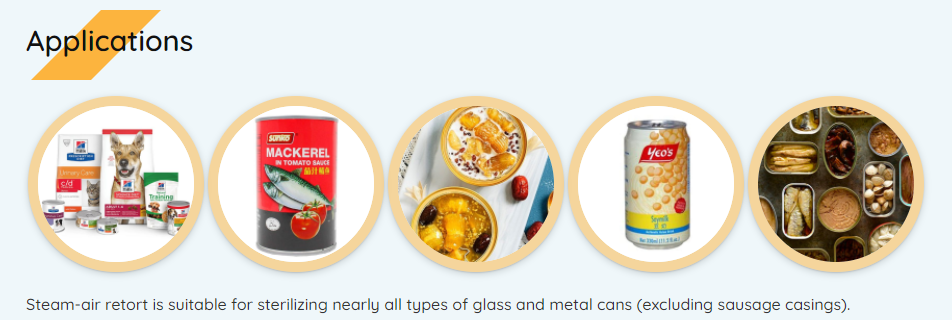

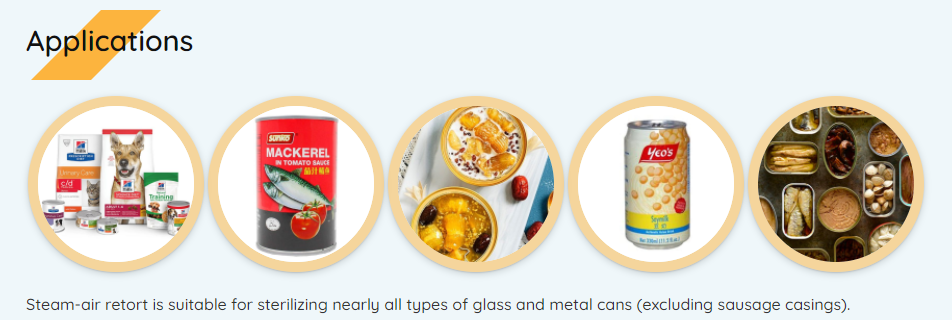

Customer Applications

This Steam Type Retort is perfect for various types of packaging containers, including:

Glass Containers: Glass jars and bottles

Metal Containers: Tinplate cans and aluminum cans

Plastic Containers: PP bottles, HDPE bottles

Soft Bag Packaging: Aluminum foil bags, transparent bags, and vacuum bags

Vacuum Bags for Cooking: Ideal for cooking applications where heat sterilization is required

Conclusion

The Automatic Steam Type Retort Autoclave Sterilizer Machine offers a highly efficient and reliable method for sterilizing food in various packaging formats. With its advanced water spray system, optional rotation for large containers, and energy-saving design, it ensures consistent sterilization results. The automated features and precise control technology make it a great choice for large-scale food processing operations that need to meet high standards for food safety and quality.