This is a highly versatile sterilizer that not only minimizes temperature variations by changing the direction of water flow, but also can select a rotating type (optional) that can be applied for large size cans and commercial pouches.

The water spray retort is suitable for a variety of packaging containers, such as heat-resistant packaging, gas-contained packaging and flexible packaging.

Glass containers: glass jars

Metal containers: tinplate cans, aluminum cans

Plastic containers: PP bottles, HDPE bottles

Soft bag packaging: aluminum foil bags, transparent bags, vacuum bags

Vacuum bags for cooking, etc.

This water spray retort controls the temperature and pressure gradually, ensuring uniform temperature distribution and stable pressure throughout the vessel which translate to consistent sterilization effect, thereby minimizing the package deformation and damage rate while maintaining the package integrity. High-level of automation enables the batch retort easy to operate and less labor intensity.

Multiple spraying methods are selectable to accommodate different packaging types such as flexible packagings, rigid containers, plastic bottles, and glass containers.

Features

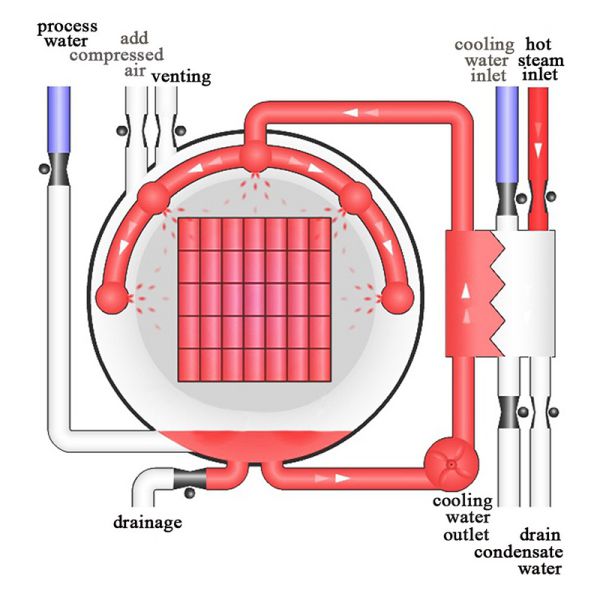

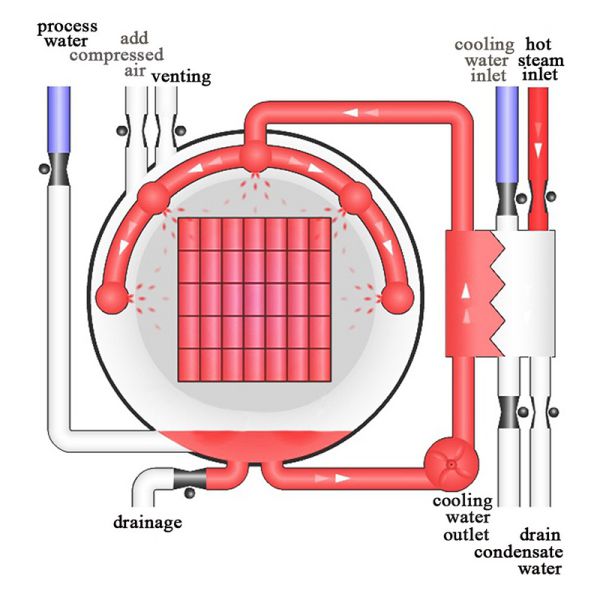

1. Dispersion of uniform water flow

By strategically switching the direction of the water flow, it becomes possible to ensure that every corner of the tank receives equal treatment. This method guarantees that all products placed on the trays are thoroughly sterilized, leaving no room for potential contamination. The system's ability to disperse the water flow evenly to the center of each tray plays a key role in maintaining the quality and safety of the sterilization process. Consistency in water flow distribution is essential for achieving optimal sterilization results and upholding high standards of product hygiene.

2. High temperature and rapid processing

By preparing hot water in advance and the heat sterilizing from the high temperature, enable high temperature sterilization in a short time.

3. Support for the large size cans and commercial pouches by rotating type (optional)

In case of the stationary type, high viscosity foods using large size cans and commercial pouches are difficult to heat sterilize to the center in a short time. By stirring with rotational motion, high viscosity food can be uniformly heated to the center in a short time, and efficiently sterilized.

4. Compatible with air-containing containers

For the air-containing container, processing with optimal conditions including the preparation temperature of the hot water tank, processing temperature, temperature curve and pressure curve (air-containing container processing system).

5. Experienced control technology

Adopting AMMU (Pattern setting instrument) to set and register the planned sterilization conditions for food sterilization (HACCP-compatible). The ideal system to prevent the mistake of the setting operation by calling up the best sterilization condition by the pattern card by one touch, it is possible to correspond from one sterilizer unit to the unmanned operation in the factory.

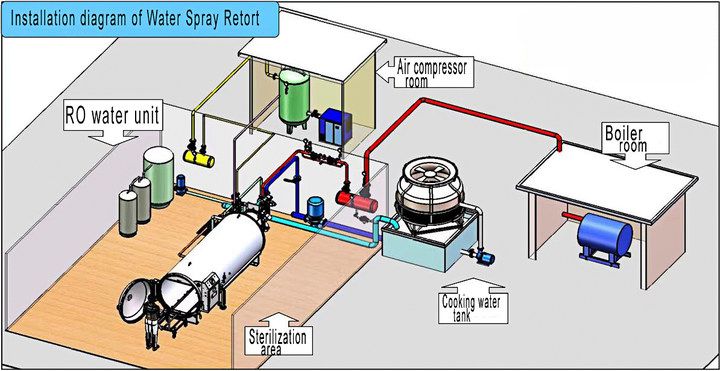

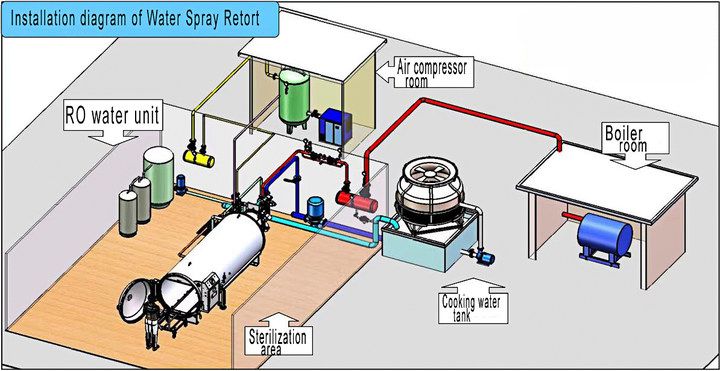

Installation Diagram

Work process

Machine details:

Customer pot: