| fuction: | |

|---|---|

| Material: | |

| Application industry: | |

| Availability: | |

| Quantity: | |

HYL OEM

HUIYILAI

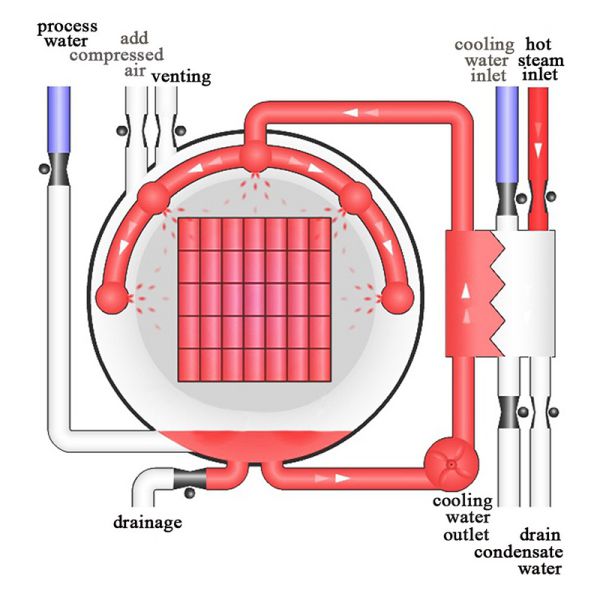

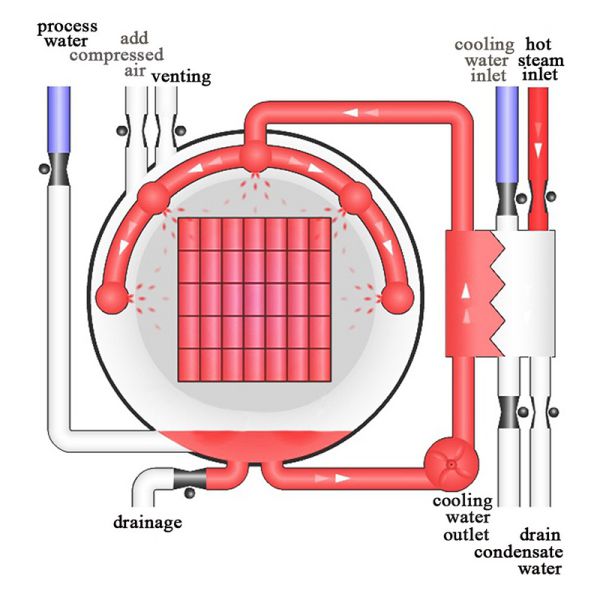

The Automatic Side Water Spray Retort Steriliser Autoclave ensures safe long-term storage of canned fish, pet food, and ready meals through precise temperature and pressure control. Using a side-mounted water spray system, it achieves uniform heat distribution (±0.5°C) across all containers, eliminating thermal gradients that could compromise sterilization. The 1200mm diameter chamber accommodates up to 5000 cans (330ml) per cycle, combining efficiency with compliance to FDA 21 CFR Part 113 and EU 2006/42/EC standards.

Dynamic Water Spray System: 360° rotating nozzles spray heated water (121-135°C) at 2-3 bar pressure, reducing sterilization time by 15% compared to static retorts.

Precision PID Control: Maintains temperature stability within ±0.3°C and pressure within ±0.1bar, with real-time data logging and automatic process validation reports.

Energy Recovery Boiler: Recycles steam condensate to pre-heat incoming water, reducing energy consumption by 40% and water usage by 30%.

Multi-Container Compatibility: Processes glass jars, metal cans, and flexible pouches (up to 200mm height), with adjustable trolley grids for different container sizes.

Safety Interlocks: Double-door interlock system and pressure-sensitive safety valves prevent accidental opening during operation, with emergency stop buttons on both sides.

Canned Seafood: Sterilizes tuna, sardines, and salmon in oil/water, extending shelf life to 2-3 years without refrigeration.

Pet Food Canning: Processes meat-based pet food in retortable pouches, ensuring bacterial inactivation (including Clostridium botulinum).

Ready-to-Eat Meals: Sterilizes fully cooked meals in trays or cans for military rations, airline meals, and emergency supplies.

Pharmaceutical Sterilization: Optional cleanroom models for sterilizing medical devices and parenteral solutions, meeting ISO 13485 requirements.

Q: What is the minimum sterilization time for low-acid foods?

A: Standard process for pH>4.6 foods is 30 minutes at 121°C, validated by biological indicators (Bacillus stearothermophilus).

Q: Can the retort handle irregularly shaped containers?

A: Yes, flexible trolley configurations accommodate jars with handles or shaped pouches, with careful load planning to ensure heat uniformity.

Q: Is a separate cooling tower required?

A: Integrated plate heat exchanger cools the retort using city water or a closed-loop system, with optional chillers for rapid cooling in hot climates.

The Automatic Side Water Spray Retort Steriliser Autoclave ensures safe long-term storage of canned fish, pet food, and ready meals through precise temperature and pressure control. Using a side-mounted water spray system, it achieves uniform heat distribution (±0.5°C) across all containers, eliminating thermal gradients that could compromise sterilization. The 1200mm diameter chamber accommodates up to 5000 cans (330ml) per cycle, combining efficiency with compliance to FDA 21 CFR Part 113 and EU 2006/42/EC standards.

Dynamic Water Spray System: 360° rotating nozzles spray heated water (121-135°C) at 2-3 bar pressure, reducing sterilization time by 15% compared to static retorts.

Precision PID Control: Maintains temperature stability within ±0.3°C and pressure within ±0.1bar, with real-time data logging and automatic process validation reports.

Energy Recovery Boiler: Recycles steam condensate to pre-heat incoming water, reducing energy consumption by 40% and water usage by 30%.

Multi-Container Compatibility: Processes glass jars, metal cans, and flexible pouches (up to 200mm height), with adjustable trolley grids for different container sizes.

Safety Interlocks: Double-door interlock system and pressure-sensitive safety valves prevent accidental opening during operation, with emergency stop buttons on both sides.

Canned Seafood: Sterilizes tuna, sardines, and salmon in oil/water, extending shelf life to 2-3 years without refrigeration.

Pet Food Canning: Processes meat-based pet food in retortable pouches, ensuring bacterial inactivation (including Clostridium botulinum).

Ready-to-Eat Meals: Sterilizes fully cooked meals in trays or cans for military rations, airline meals, and emergency supplies.

Pharmaceutical Sterilization: Optional cleanroom models for sterilizing medical devices and parenteral solutions, meeting ISO 13485 requirements.

Q: What is the minimum sterilization time for low-acid foods?

A: Standard process for pH>4.6 foods is 30 minutes at 121°C, validated by biological indicators (Bacillus stearothermophilus).

Q: Can the retort handle irregularly shaped containers?

A: Yes, flexible trolley configurations accommodate jars with handles or shaped pouches, with careful load planning to ensure heat uniformity.

Q: Is a separate cooling tower required?

A: Integrated plate heat exchanger cools the retort using city water or a closed-loop system, with optional chillers for rapid cooling in hot climates.