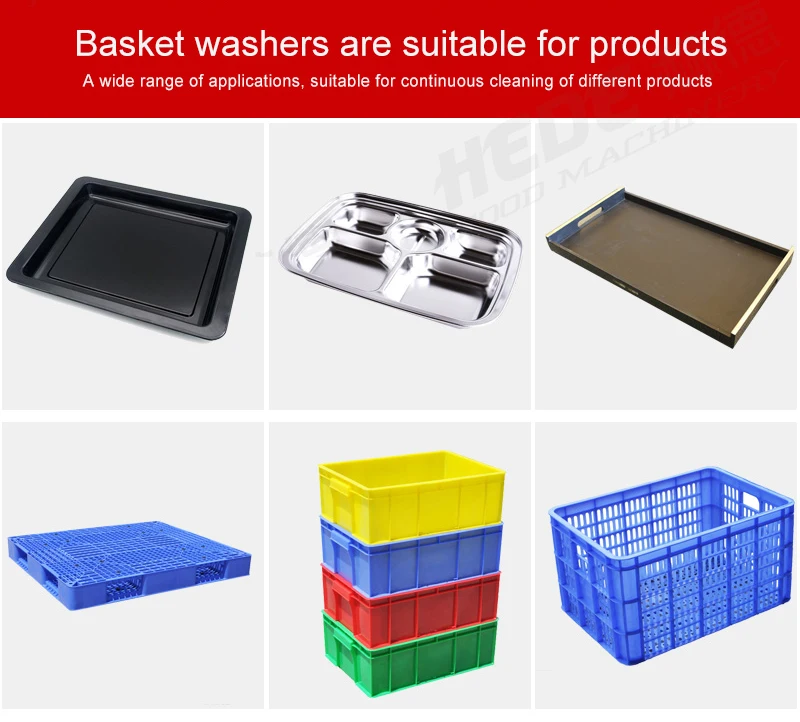

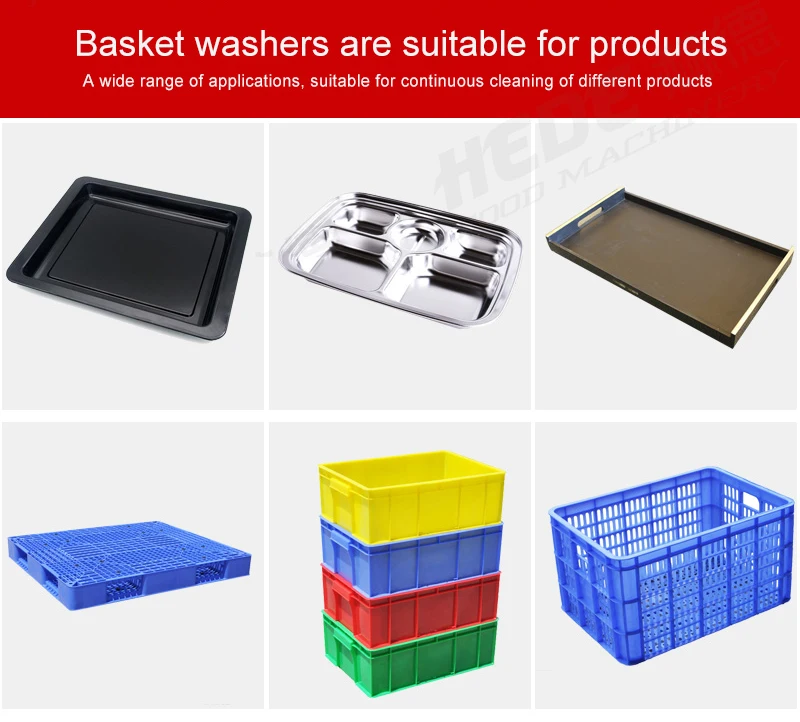

Product Overview

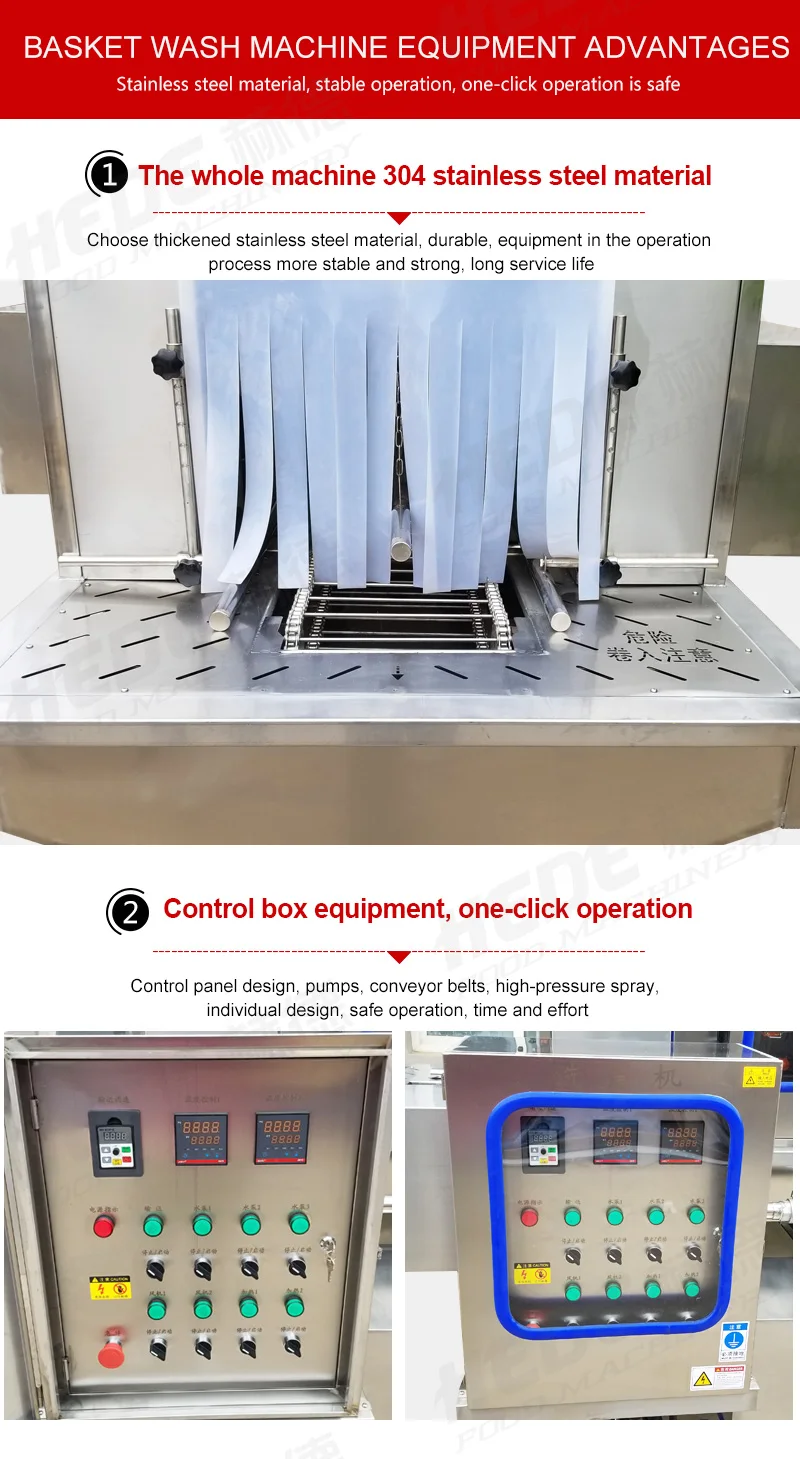

The industrial crates washer and drying machine (also known as turnover tray/basket washer dryer) is a high-efficiency automatic cleaning equipment designed to replace manual labor for container sanitization. Manufactured by HUIYILAI with food grade SS304 stainless steel, this machine integrates pre-washing, deep washing, rinsing, and drying into one seamless process, ensuring thorough cleanliness without dead corners. It is engineered for durability, stability, and compliance with food safety and industrial hygiene standards, making it an indispensable tool for businesses requiring consistent container cleaning.

Key Features

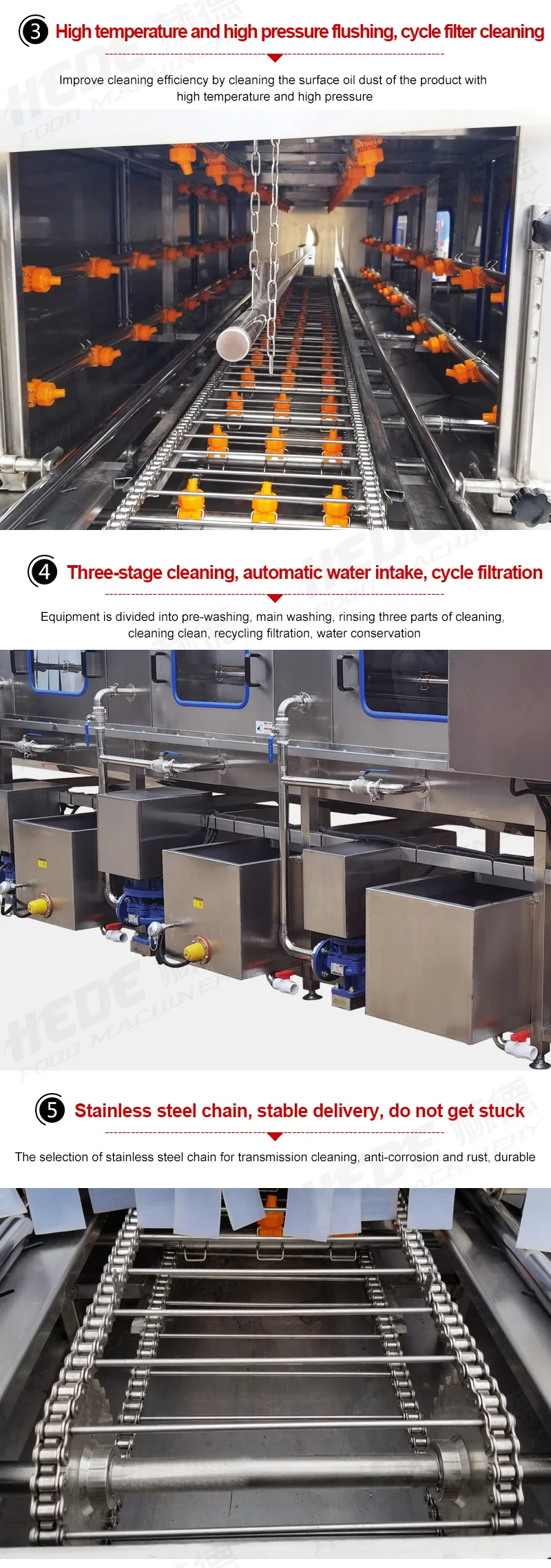

Four-Stage Cleaning & Drying Process

Equipped with a complete four-stage workflow (pre-washing, deep washing, rinsing, drying), the machine removes oil, dust, and residues effectively. Detergent can be added to the first or second stage for heavy soiling, while the final drying step eliminates surface moisture, enabling immediate reuse of containers.

Adjustable Nozzles & Customizable Cleaning Space

Food grade high-temperature resistant plastic or stainless steel nozzles are installed on the top, bottom, left, and right of the washing tunnel. Their adjustable angles eliminate cleaning dead corners. Additionally, the left-right adjustable guardrail rails and up-down adjustable top shower pipe accommodate different sizes and heights of crates, trays, and baskets.

Variable-Speed Control & Stable Conveyance

The motor supports mechanical stepless adjustment or variable-frequency adjustable speed, allowing users to set optimal washing time for different containers. The stainless steel transmission chain ensures stable conveyance, anti-corrosion, rust resistance, and no material jamming during operation.

Water-Saving & Efficient Design

Featuring automatic water recycling and filtration systems, the machine reuses water across cleaning stages, significantly reducing water consumption. The high-quality stainless steel hot water pump delivers high-temperature and high-pressure flushing, boosting cleaning efficiency while maintaining energy savings.

Technical Specifications

Parameter | Details |

Material | Food grade SS304 stainless steel (main body) |

Model | HYL OEM |

Heating Method | Steam heating or electric heating (automatic temperature control) |

Speed Control | Mechanical stepless adjustment / Variable-frequency adjustable |

Cleaning Stages | Pre-washing, deep washing, rinsing, drying |

Nozzle Material | Food grade high-temperature resistant plastic / Stainless steel |

Control Mode | Integrated control panel (one-click operation) |

Conveyor Chain | Stainless steel (anti-corrosion, rust-resistant) |

Applicable Container Types | Plastic crates, trays, baskets, stainless steel trays, pallets, tires, etc. |

Application Areas

Food Processing Industry

Ideal for cleaning turnover containers used in nursery, meat, vegetables, fruits, bakery, fish, shrimp, cheese, bread, chocolate, and chicken processing. It meets strict food safety requirements, ensuring contamination-free production.

Medical & Sanitary Field

Suitable for sanitizing stainless steel trays and containers in hospitals, laboratories, and medical supply facilities, adhering to hygiene standards for medical equipment.

General Industrial Applications

Can clean non-food containers such as plastic pallets, tires, hardware trays, and industrial baskets, supporting manufacturing, logistics, and warehousing industries.

Operation & Safety

User-Friendly Operation

The integrated control panel features one-click operation, with independent controls for pumps, conveyor belts, and high-pressure spray. Only 1-2 operators are required, saving time and labor.

Safety Protection

Equipped with guardrails and a sealed control box to prevent accidental contact with moving parts. The stainless steel structure is non-toxic, corrosion-resistant, and compliant with industrial safety directives.

Easy Maintenance

Thickened SS304 stainless steel material ensures long service life. Routine maintenance involves cleaning nozzles and filters, with clear guidelines provided in the user manual.

Customization Support

We offer tailored solutions to meet specific customer needs:

Adjustment of machine size and washing tunnel width for special-sized containers.

Customization of cleaning time, water pressure, and temperature parameters.

Optional heating methods (steam or electric) based on on-site conditions.

Additional nozzle configurations for high-demand cleaning scenarios.