Product Overview

The DZ460 Skin Vacuum Packaging Machine is a high-performance packaging solution designed for reliable vacuum skin sealing across multiple industries. Crafted with food-grade SS304 stainless steel, this machine meets strict safety standards (CE certified) and delivers exceptional protection for products by removing air, preventing oxidation, mold, moth infestation, and dampness. Ideal for both small-scale operations and dynamic workplaces, it excels in preserving the freshness of fresh meat, seafood, and other perishables, while also optimizing product presentation for retail and commercial use. With a compact footprint and mobile design, it addresses the needs of narrow workspaces or frequent site relocations without compromising efficiency.

Key Features

Compact & Mobile Design

Tailored for flexibility, the DZ460 is engineered to operate in relatively narrow sites and supports frequent movement. Its space-saving structure ensures it integrates seamlessly into diverse production lines, from small workshops to large factories.

Intuitive Touch Screen Control

Equipped with a programmable control system and touch screen panel, the machine simplifies operation. Users only need to close the vacuum chamber cover and follow preset procedures to complete vacuum pumping, reducing training time and human error.

Premium Food-Grade Construction

The main body is made of food-grade SS304 stainless steel, ensuring durability, corrosion resistance, and compliance with food safety regulations. This material is easy to clean, making it suitable for hygiene-sensitive industries like food and medical.

Real-Time Fault Monitoring

A built-in fault real-time prompting function alerts operators immediately to issues, minimizing downtime and ensuring smooth production. Quick problem identification helps maintain consistent packaging quality.

Transparent Vacuum Chamber

The vacuum chamber features transparent plexiglass, allowing operators to monitor the entire vacuum pumping process visually. This transparency enhances quality control and ensures each product is sealed correctly.

Technical Specifications

Parameter | Details |

Model | DZ460 (HYL OEM) |

Vacuum Chamber Size | 70050060 mm |

Power Supply | 380V |

Packaging Efficiency | 2-3 pcs/min |

Construction Material | Food-grade SS304 stainless steel |

Certification | CE, etc. |

Core Control System | Programmable control + Touch screen panel |

Mold Compatibility | Replaceable & Customizable molds |

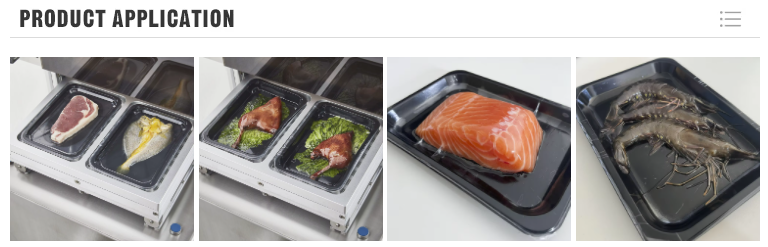

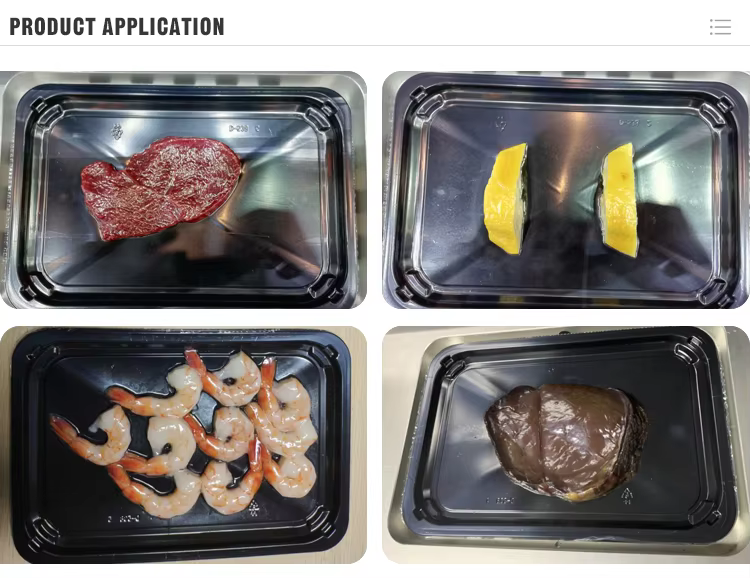

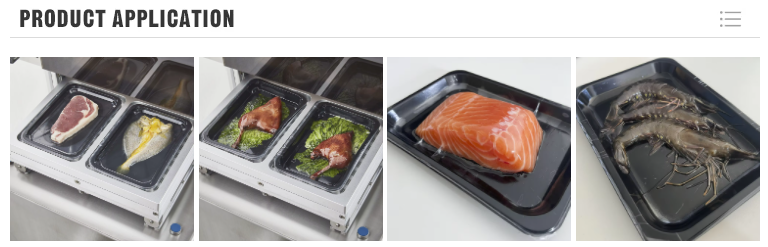

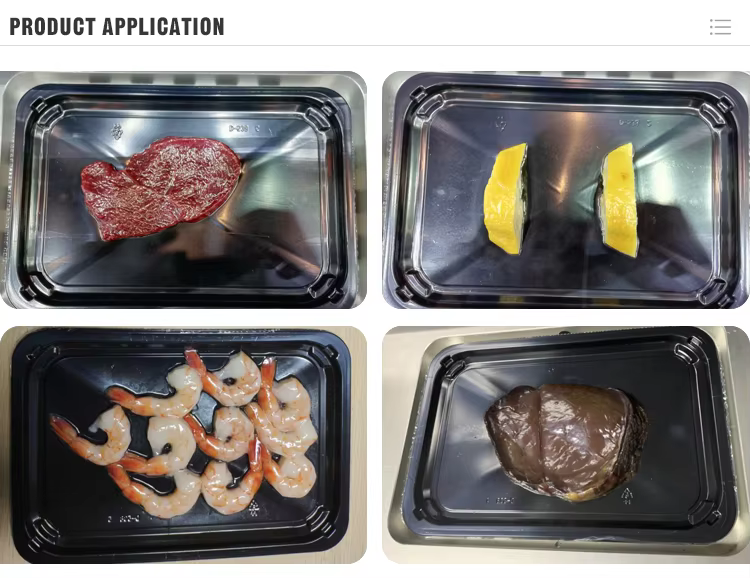

Application Areas

Food Industry

Perfect for packaging fresh meat, seafood, processed snacks, and perishables. It extends shelf life, locks in flavors, and maintains ingredient freshness, ideal for butcher shops, seafood markets, and food manufacturers.

Medical & Pharmaceutical

Suitable for sealing medical devices, sterile supplies, and pharmaceutical products. The airtight seal prevents contamination, ensuring compliance with medical industry standards.

Chemical & Commodity

Protects chemical reagents, electronic components, and daily commodities from moisture, oxidation, and external damage. Ideal for warehouses and manufacturing facilities.

Apparel & Beverage

Seals clothing, textiles, and beverage accessories to prevent dust accumulation and maintain product integrity during storage and transportation.

Operation & Safety

Simple Operation Steps

Place the product in the vacuum chamber.

Close the chamber cover firmly.

Select preset parameters via the touch screen (vacuum time, cooling time, temperature).

Start the machine; it automatically completes vacuum pumping and sealing.

Safety Guarantees

The machine’s robust SS304 structure ensures stability during operation. The transparent chamber eliminates blind spots, and the fault prompting function prevents unsafe operation due to equipment malfunctions.

Customization Support

We offer flexible customization options to meet unique packaging needs:

Mold Customization: Replaceable molds are available; custom molds can be designed based on product size, shape, and packaging requirements.

Process Adjustment: Parameters like vacuum time and cooling temperature can be tailored to specific product characteristics.

FAQ

What voltage does the DZ460 require?

The machine uses a 380V power supply, suitable for industrial and commercial electrical systems.

Is it easy to move the machine between sites?

Yes, its compact design and lightweight structure (compared to large industrial machines) make it easy to relocate for on-site packaging needs.

Is the material safe for direct food contact?

Absolutely. The main body is made of food-grade SS304 stainless steel, which is non-toxic, corrosion-resistant, and meets global food safety standards.

How can I troubleshoot if the machine stops working?

The real-time fault prompting function displays error reasons. For further support, our team provides video technical support and online assistance.