Product Overview

The Commercial Vacuum Frying Machine is a cutting-edge food processing equipment leveraging low temperature vacuum frying technology (80-120℃). It integrates frying and dehydration, offering a healthy alternative to traditional high-temperature frying. With 15 years of R&D experience, this machine boasts 2-3 times the output capacity of ordinary vacuum fryers, producing crispy, non-greasy foods while retaining nutrients, color, and original flavors. Key variants include Vegetable Processing Line Vacuum Fryer, Fruit And Vegetable Vacuum Fryer, and Commercial Air Fryer, perfect for food factories and snack producers focusing on healthy products.

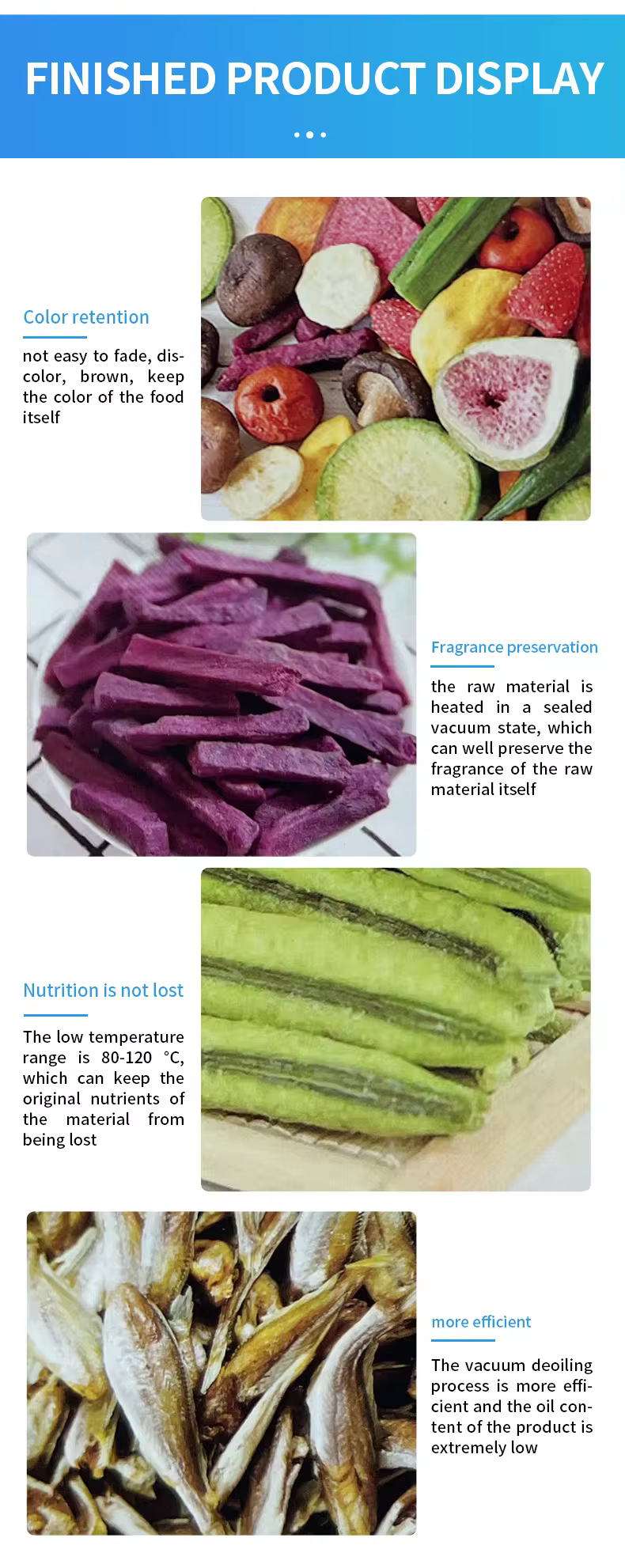

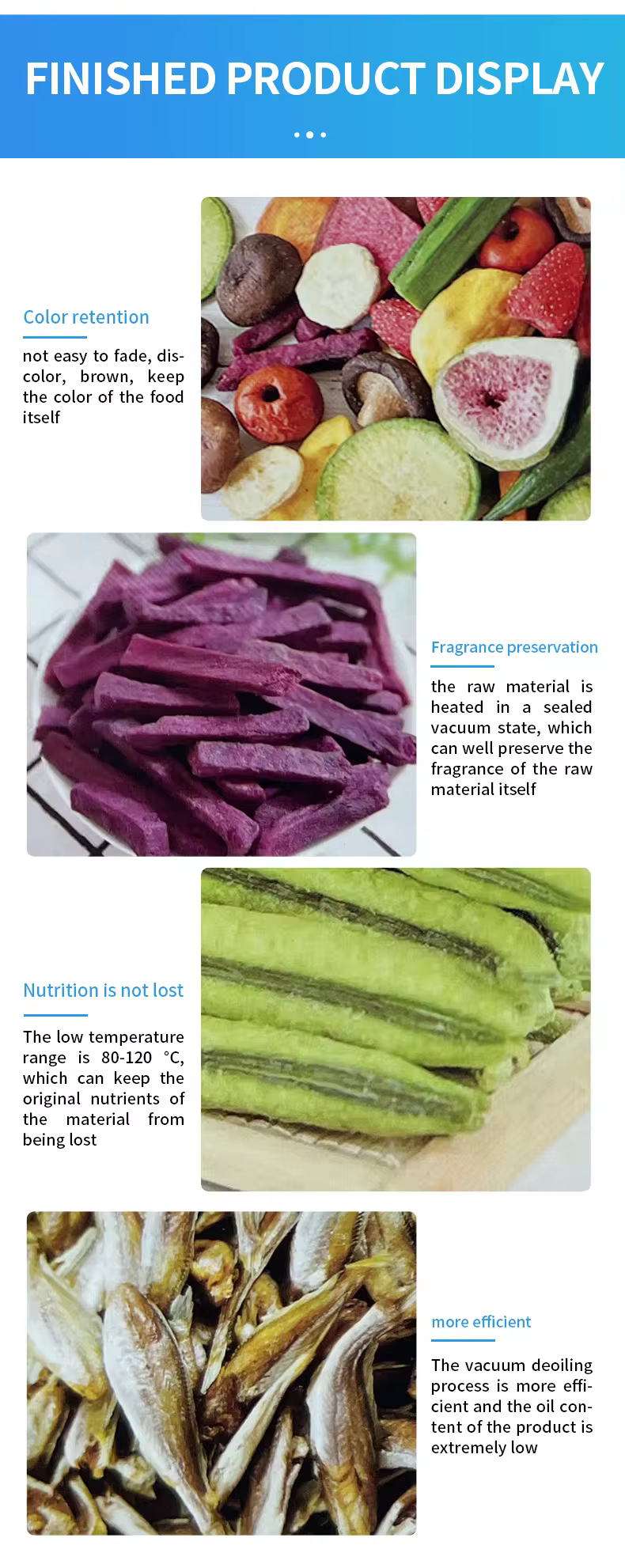

Key Features

Low-Temperature Nutrition Preservation

Operating at 80-120℃ low temperature, the machine minimizes nutrient loss caused by high heat—preserving vitamins, minerals, and antioxidants in fruits, vegetables, and other ingredients. Unlike traditional fried foods (40%-50% oil content), vacuum-fried products have only 10%-20% oil content, crisp but not greasy.

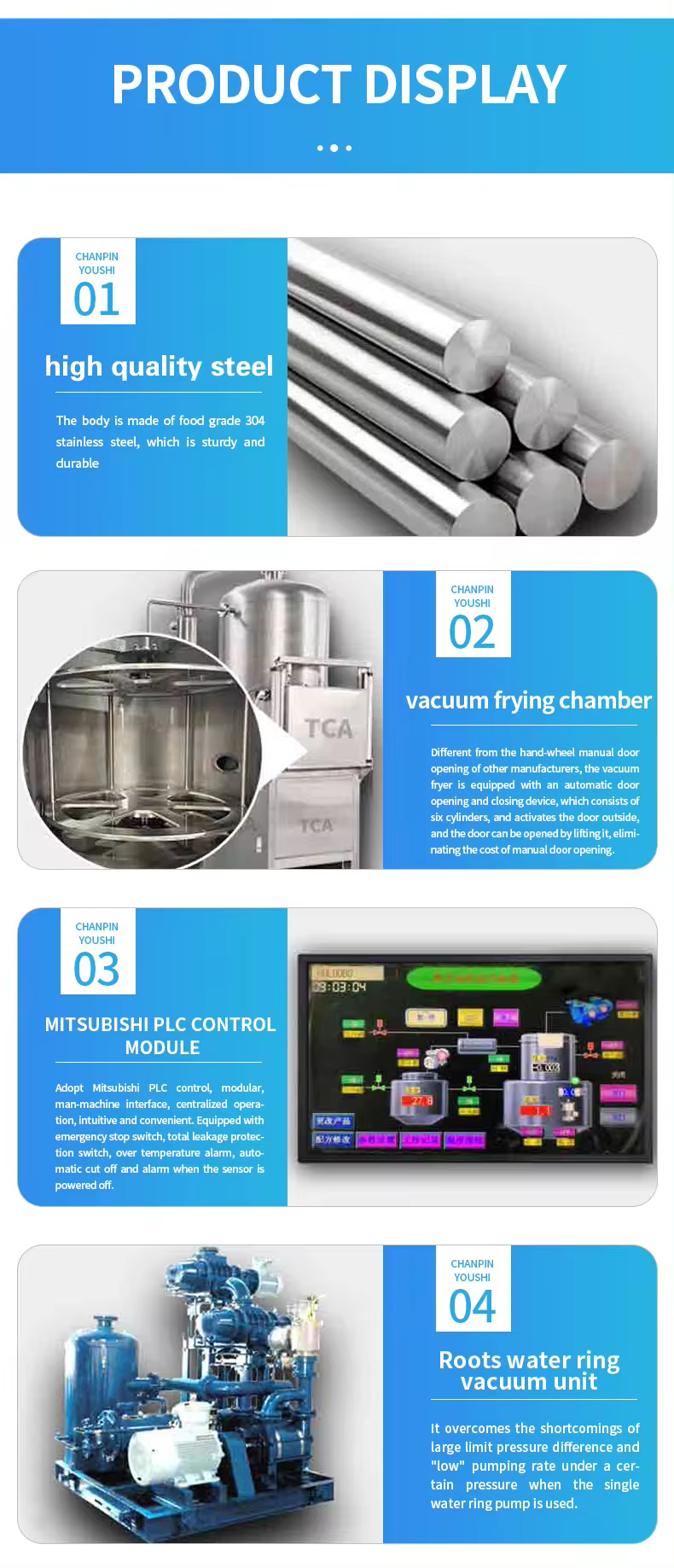

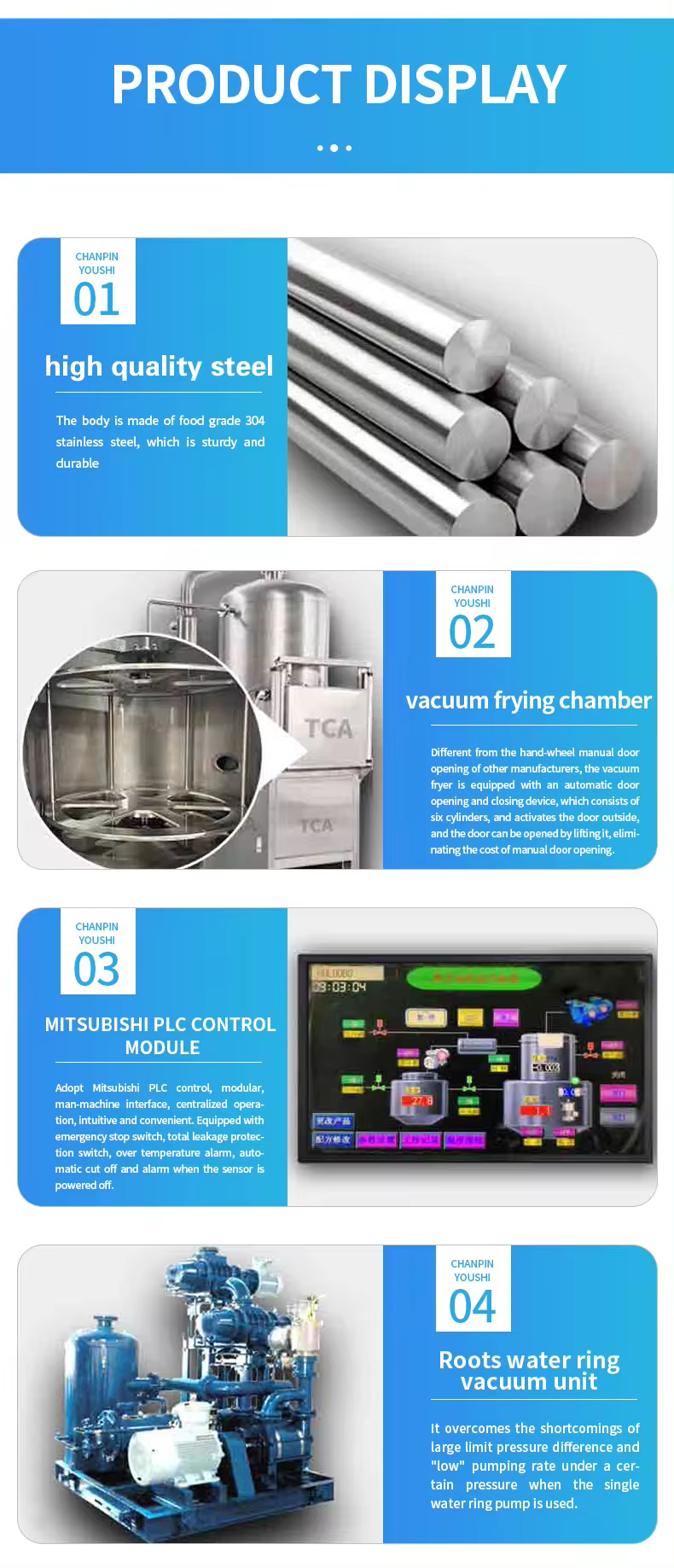

High-Quality & Durable Build

The entire machine body is made of food grade 304 stainless steel, ensuring sturdiness, corrosion resistance, and compliance with food safety regulations. The robust structure withstands long-term high-intensity production and is easy to clean.

Intelligent PLC Control System

Adopting Mitsubishi PLC control module with a man-machine interface, the machine enables centralized operation—intuitive and convenient. It is equipped with safety features such as an emergency stop switch, total leakage protection switch, over-temperature alarm, and automatic cut-off when the sensor is powered off.

Automatic Door & Efficient Vacuum Unit

Unlike manual hand-wheel doors, this machine features an automatic door opening and closing device (six cylinders) for easy operation, eliminating manual labor costs. The Roots water ring vacuum unit overcomes the shortcomings of single water ring pumps, ensuring stable vacuum pressure and efficient dehydration.

Technical Specifications

Parameter | Details |

Material | Food grade 304 stainless steel (body & inner pot) |

Operating Temperature | 80-120℃ (adjustable) |

Vacuum System | Roots water ring vacuum unit |

Control System | Mitsubishi PLC control, man-machine interface |

Door Opening Mode | Automatic (six cylinders) |

Deoiling Method | Vacuum deoiling process |

Oil Content of Products | 10%-20% |

Output Capacity | 2-3 times that of ordinary vacuum fryers |

Power Supply | Customizable (220V/380V) |

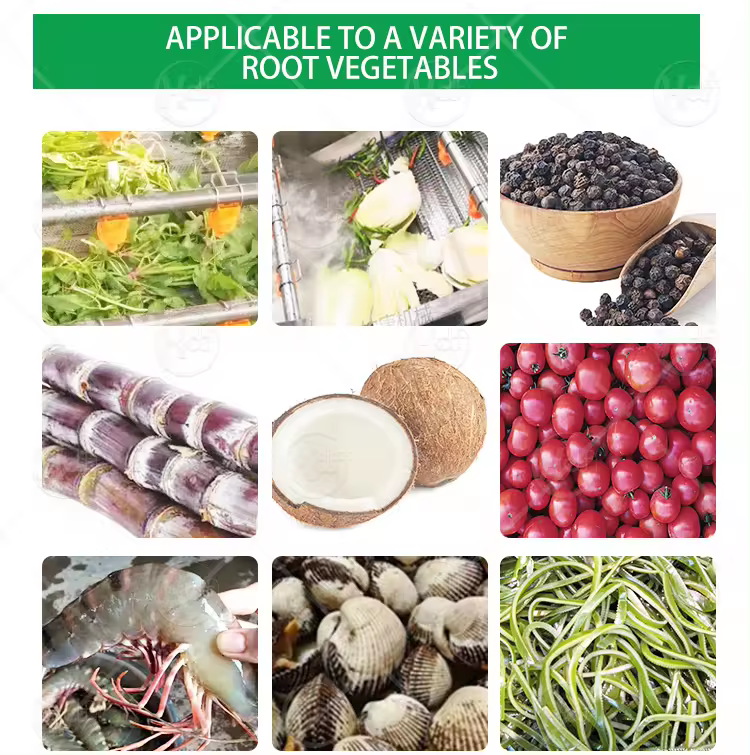

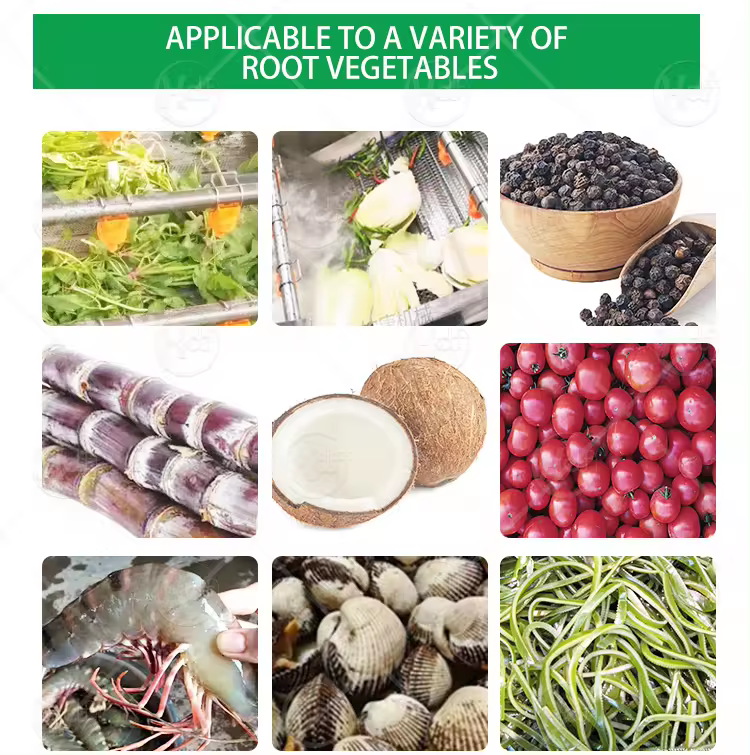

Application Areas

Fruit Processing

Ideal for frying apple, kiwi, banana, jackfruit, persimmon, strawberry, grape, peach, and pear. The vacuum environment preserves the fruits’ natural color and sweetness, producing crispy fruit snacks.

Vegetable Processing

Suitable for processing tomato, sweet potato, potato, kidney bean, mushroom, garlic, carrot, green pepper, and pumpkin. The low-temperature frying retains vegetables’ crunchiness and nutritional value, creating popular healthy snacks.

Dried Fruits & Nuts

Perfect for frying jujube, peanut, and other dried fruits/nuts, enhancing their crispness and extending shelf life without adding excessive oil.

Aquatic & Meat Products

Can process aquatic products (e.g., dried fish, shrimp) and animal meat, producing low-oil, crispy snacks with preserved original flavors.

Operation & Safety

Simple & Efficient Operation

The centralized PLC control panel allows one-click setting of temperature, vacuum degree, and processing time. The automatic door and deoiling system reduce manual intervention, improving production efficiency.

Multiple Safety Protections

Equipped with leakage protection, over-temperature alarm, emergency stop, and sensor power-off alarm. The closed vacuum environment prevents oil splashing, ensuring a safe working environment for operators.

Customization Support

We provide personalized customization to match your production requirements:

Capacity Customization: Tailor output capacity based on your production scale (100kg/h-500kg/h).

Inner Pot Size: Adjust the inner pot diameter and depth for specific ingredients.

Control System Upgrade: Opt for a smart control system with data recording and remote monitoring.

Additional Functions: Add automatic feeding, discharging, or oil filtration systems for seamless production lines.