Product Description:

Why Opt for a Vacuum Freeze Dryer?

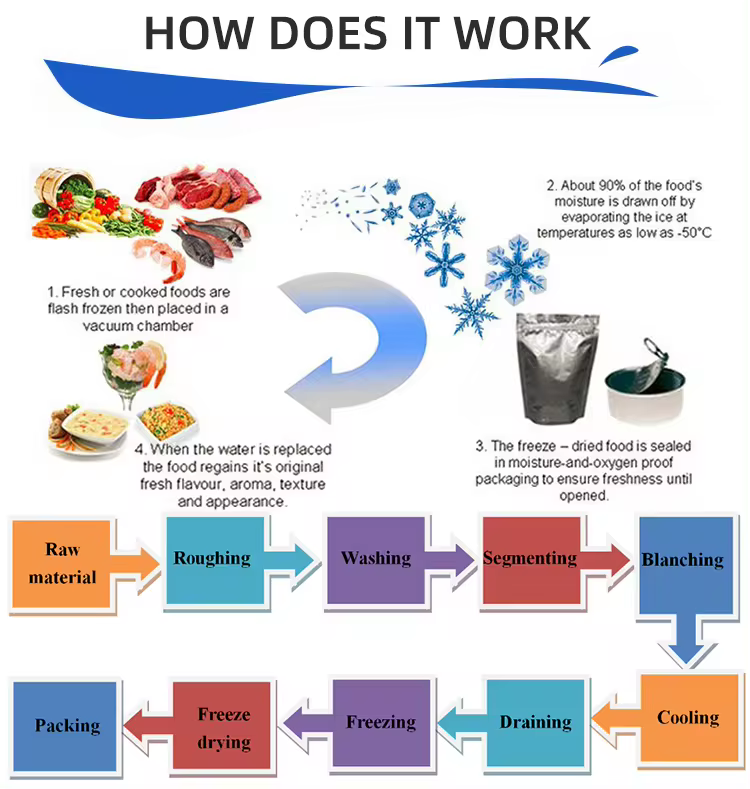

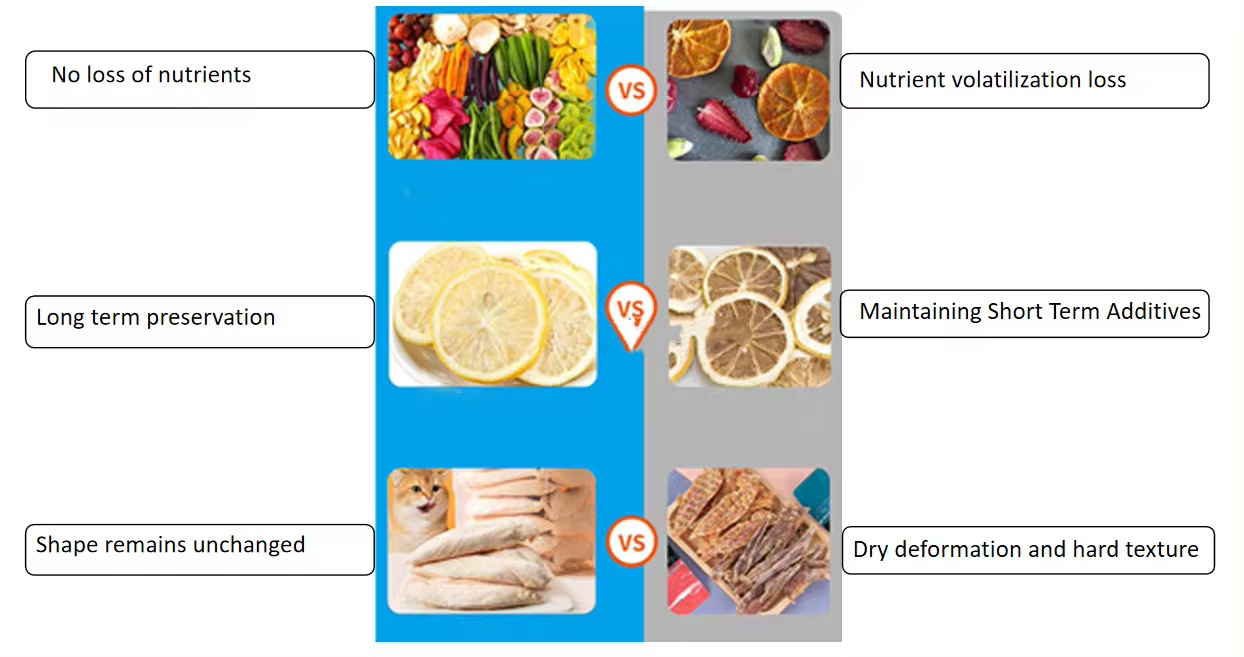

Vacuum freeze drying stands out as the ultimate solution for preserving the full essence of food. It not only retains the natural colors, flavors, and textures of fruits, vegetables, and meats, but it also ensures these qualities are maintained for extended periods. By gently removing moisture at low temperatures, this method avoids the typical degradation that happens with conventional freezing, ensuring that the food keeps its nutritional value and fresh taste. If you’re after food that stays as vibrant and nutritious as the day it was made—whether for long-term storage or convenience—freeze-drying offers an unparalleled way to keep your products at their best.

Technical Parameter:

Model | HYLXFD-200 | HYLXFD-300 | HYLXFD-500 | HYLXFD-600 | HYLXFD-900 | HYLXFD-1200 |

Feed rate of extraction solution containing 45% dry matter (kg/h) | 474 | 711 | 1185 | 1423 | 1897 | 12845 |

Capacity(kg) | 220 | 330 | 544 | 660 | 872 | 1320 |

24 hours output (kg/day) | 5280 | 7920 | 13066 | 15840 | 20928 | 31680 |

Feed rate of extraction solution containing 25% dry matter (kg/h) | 313 | 469 | 780 | 937 | 1249 | 1874 |

Capacity(kg) | 81 | 121 | 201 | 241 | 322 | 482 |

24 hours output (kg/day) | 1933 | 2900 | 4826 | 5800 | 7728 | 11600 |

Feed rate of extraction solution containing 15% dry matter (kg/h) | 170 | 256 | 427 | 512 | 684 | 1022 |

Capacity(kg) | 26 | 40 | 65 | 79 | 105 | 158 |

24 hours output (kg/day) | 632 | 948 | 1573 | 1896 | 2520 | 3792 |

Freezing temperature | -30℃~-60℃(Can design) |

Condenser temperature | -50℃~-80℃(Can design) |

Heating way | Silicone oil ,Electric heating |

Vacuum degree | ≥1Pa |

Remark: Here also Can produce vacuum freeze-drying machines ranging from 5kg to 3000kg according to customer requirements |

Equipment Characteristics:

Our continuous vacuum freeze-drying system redefines efficiency in food processing, especially for handling single raw materials. By eliminating traditional bottlenecks like air breaking, ice melting, and re-vacuuming, it maximizes throughput and slashes energy costs. Compared to batch systems, this technology reduces power usage by 30% and cuts energy consumption per unit output by 25%.

Key Benefits:

Smart Heating & Cooling: The system integrates heat recovery refrigeration, utilizing silicone oil or electric heating to achieve maximum operational efficiency with minimal energy use, all while maintaining optimal drying conditions.

Advanced Refrigeration: With its dual-stage refrigeration, the system dynamically adapts to production load variations, ensuring precise cooling capacity and energy optimization at all times.

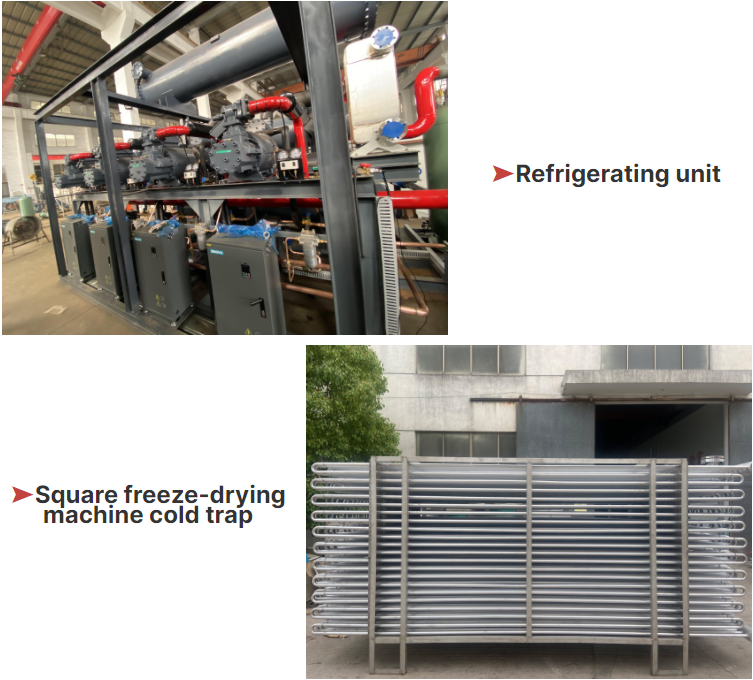

Flexible Production Layout: This system supports both rectangular and circular configurations, featuring built-in cold traps and an automatic ice-melting system. It allows seamless adjustments to handle diverse production conditions and ensures uniform drying.

Tailored for large-scale food production, this continuous freeze-drying system is built to reduce operational costs while preserving food quality and extending shelf life.

Machine Details :

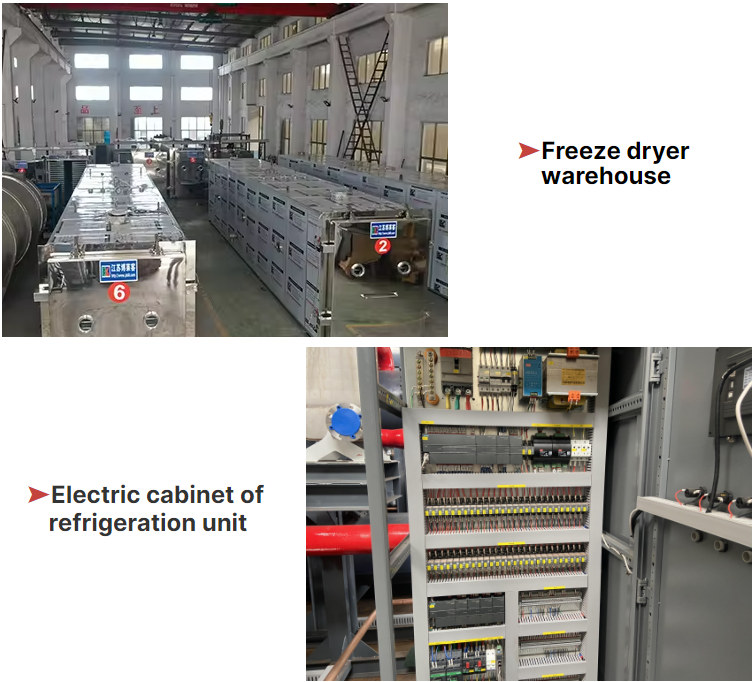

Our freeze-drying systems are engineered for peak performance and lasting durability, packed with advanced features for enhanced efficiency.

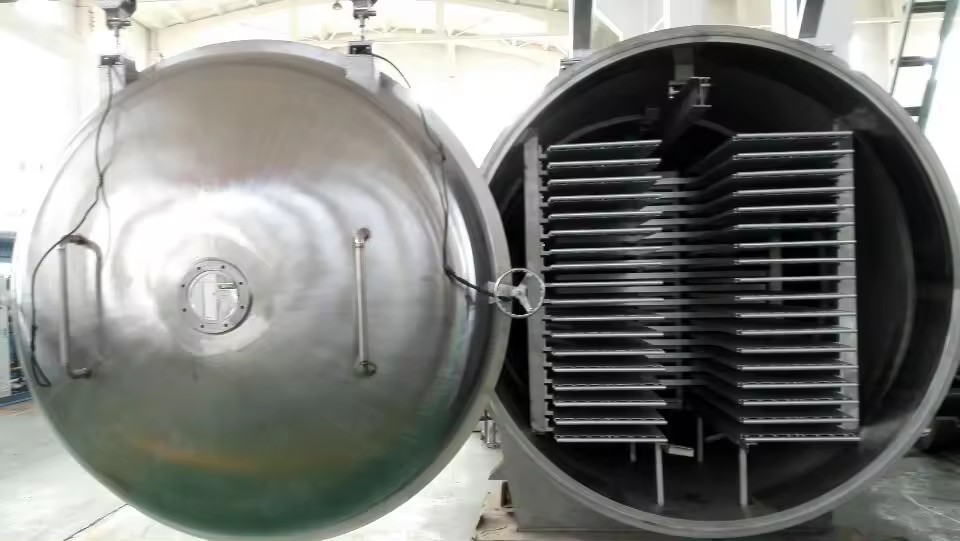

Aluminum Alloy Radiant Plate: Crafted from high-efficiency aluminum alloy, this radiant plate ensures uniform heating, maximizing the drying process for consistent quality.

Cold Traps (Circular & Square): Featuring both circular and square cold traps, these are designed for effective moisture capture, helping maintain vacuum conditions and improve operational efficiency across various product types.

Freeze Dryer Facility: Equipped with cutting-edge machinery, our facility is capable of large-scale freeze-drying. Each unit is rigorously tested, ensuring it meets the highest performance and quality standards.

High-Efficiency Refrigeration: The refrigeration system is optimized for energy efficiency, automatically adjusting to production loads while maintaining consistent cooling performance.

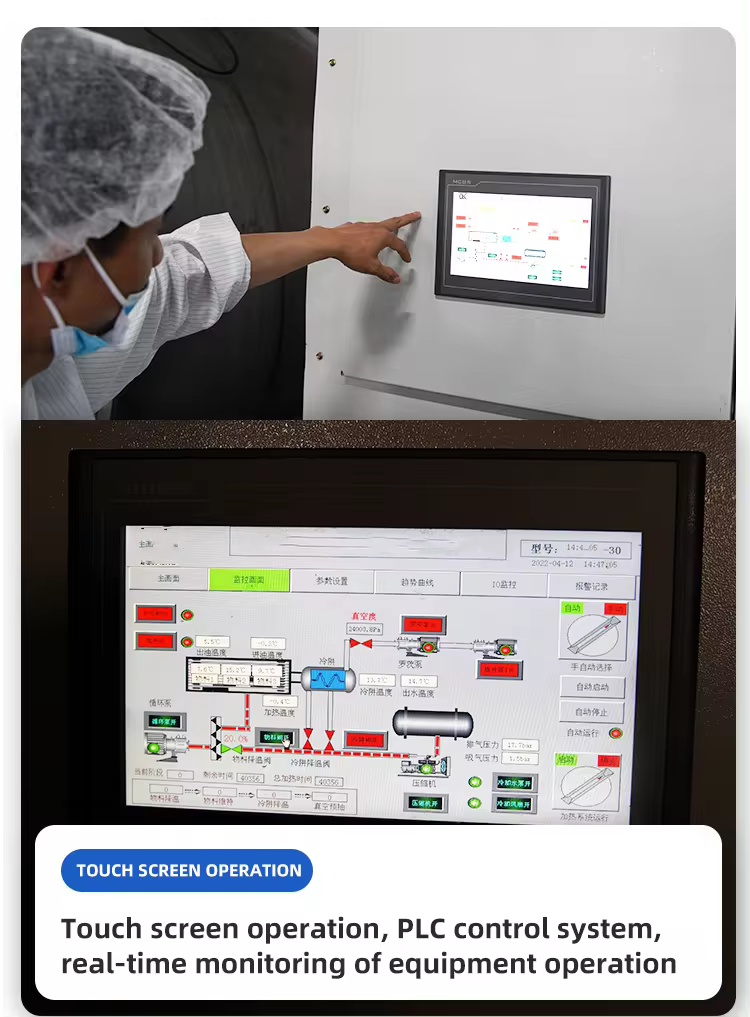

Intuitive PLC Control System: The user-friendly touch screen interface provides real-time monitoring, offering precise control over each freeze-drying cycle for streamlined operations.

Customer site pot:

Explore the real-world impact of our advanced freeze-drying systems across industries:

Superior Preservation, Every Time: Our freeze-drying technology locks in the vibrant color, rich flavor, and essential nutrients of diverse foods—whether it’s fruits, vegetables, or proteins—ensuring they retain their natural appeal and nutritional value for extended periods.

Seamless Large-Scale Production: Engineered for high-volume operations, our systems operate efficiently in expansive facilities, effortlessly keeping up with the demands of large-scale production while maintaining the quality of the end product.

Tailored Solutions for Various Food Types: Whether you're working with delicate fruits, hearty herbs, or protein-rich meats, our machines offer versatile freeze-drying solutions that are customized to preserve each ingredient's unique qualities.

Precision for Perfection: Equipped with cutting-edge control systems, our machines expertly regulate temperature and moisture levels, providing perfect freeze-drying conditions that guarantee consistent, high-quality results throughout the production process.

Welcome Your Inquiry!

At HUIYILAI, we provide innovative freeze-drying solutions that cater to a wide range of production scales, from compact 1m² units to high-capacity 200m² systems. Our equipment is designed to maximize efficiency and quality for any operation size. Whether you're focused on small-batch production or large-scale output, we’re here to offer tailored advice and the technical expertise to match your unique needs. Reach out to us today, and let’s collaborate to enhance your production efficiency with our cutting-edge systems.