Industrial Large-scale Vacuum Fruit Food Freeze Dryer For Industrial Food Freeze Drying Process Machine

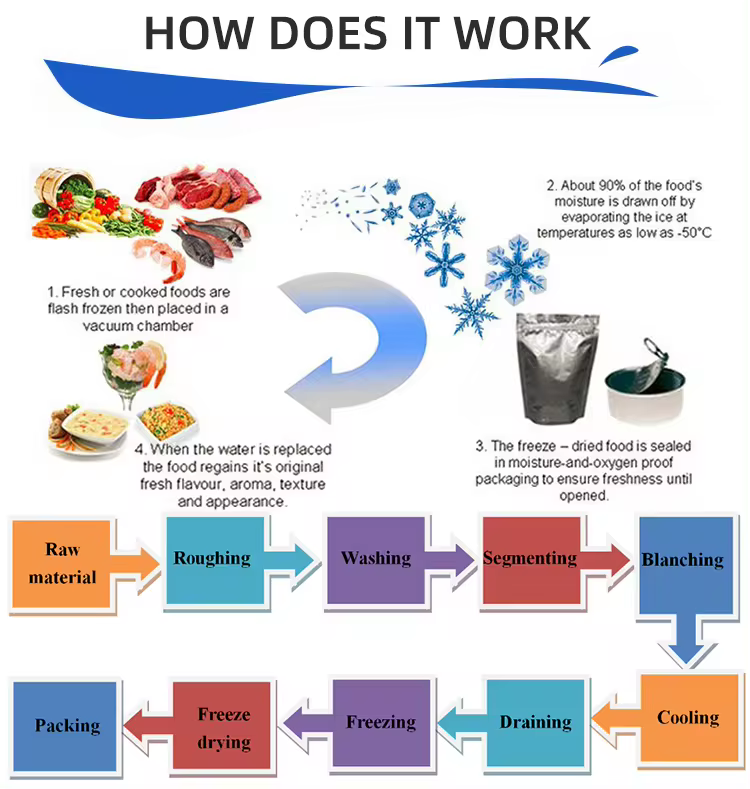

Why choose vacuum freeze dryer?

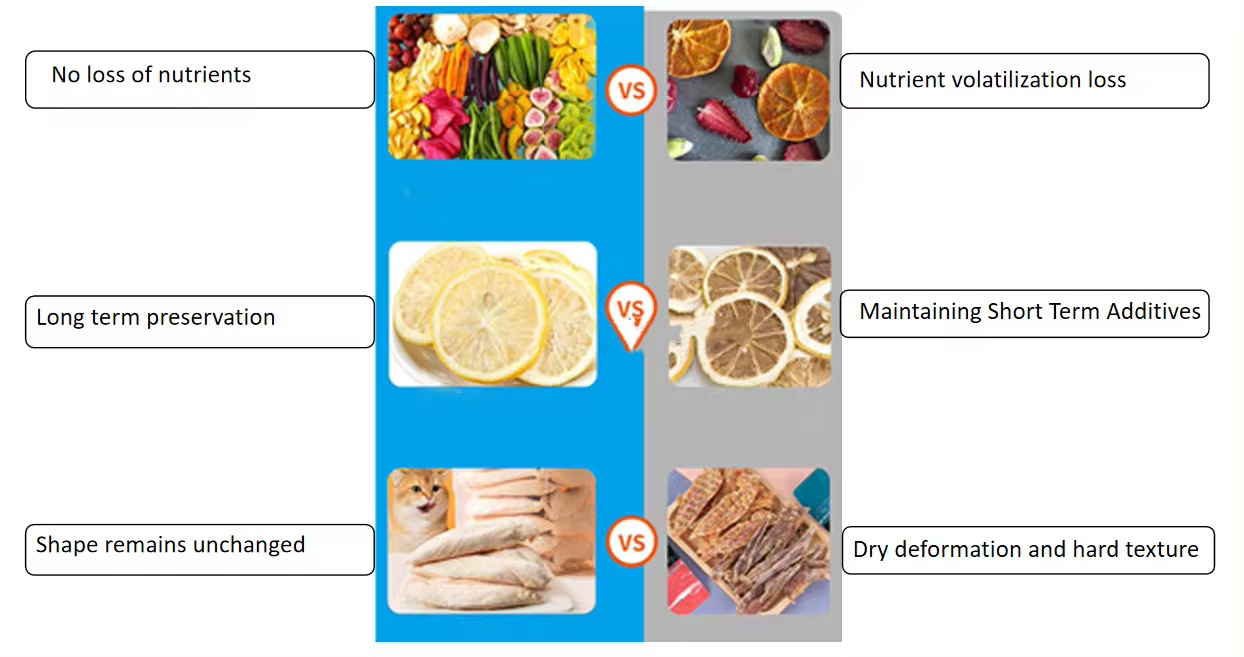

Maximizing the preservation of the color, aroma, and taste of food, such as keeping the natural pigments of vegetables unchanged, and minimizing the loss of various aromatic substances; Freeze drying is better for preserving protein containing foods than regular cryopreservation.

Technical Parameter:

Model | HYLXFD-200 | HYLXFD-300 | HYLXFD-500 | HYLXFD-600 | HYLXFD-900 | HYLXFD-1200 |

Feed rate of extraction solution containing 45% dry matter (kg/h) | 474 | 711 | 1185 | 1423 | 1897 | 12845 |

Capacity(kg) | 220 | 330 | 544 | 660 | 872 | 1320 |

24 hours output (kg/day) | 5280 | 7920 | 13066 | 15840 | 20928 | 31680 |

Feed rate of extraction solution containing 25% dry matter (kg/h) | 313 | 469 | 780 | 937 | 1249 | 1874 |

Capacity(kg) | 81 | 121 | 201 | 241 | 322 | 482 |

24 hours output (kg/day) | 1933 | 2900 | 4826 | 5800 | 7728 | 11600 |

Feed rate of extraction solution containing 15% dry matter (kg/h) | 170 | 256 | 427 | 512 | 684 | 1022 |

Capacity(kg) | 26 | 40 | 65 | 79 | 105 | 158 |

24 hours output (kg/day) | 632 | 948 | 1573 | 1896 | 2520 | 3792 |

Freezing temperature | -30℃~-60℃(Can design) |

Condenser temperature | -50℃~-80℃(Can design) |

Heating way | Silicone oil ,Electric heating |

Vacuum degree | ≥1Pa |

Remark: Here also Can produce vacuum freeze-drying machines ranging from 5kg to 3000kg according to customer requirements |

Equipment Characteristics:

Continuous freeze-drying of food has a high yield, and the continuous processing of single raw materials is particularly advantageous for food production. The equipment not only makes the entire production continuous and efficient, but also facilitates the control of the freezing sublimation process and conditions, simplifying manual operations and management. Continuous production eliminates the downtime and loading and unloading time of batch production, saves processes such as air breaking, ice melting, cooling, secondary heating, refrigeration,and re vacuuming, and has high production efficiency. Compared with batch production with the same production capacity, the installed power can be reduced by 21% to 30%, the supporting refrigeration capacity can be reduced by 409%, and the energy consumption per unit output can be reduced by about 25%.

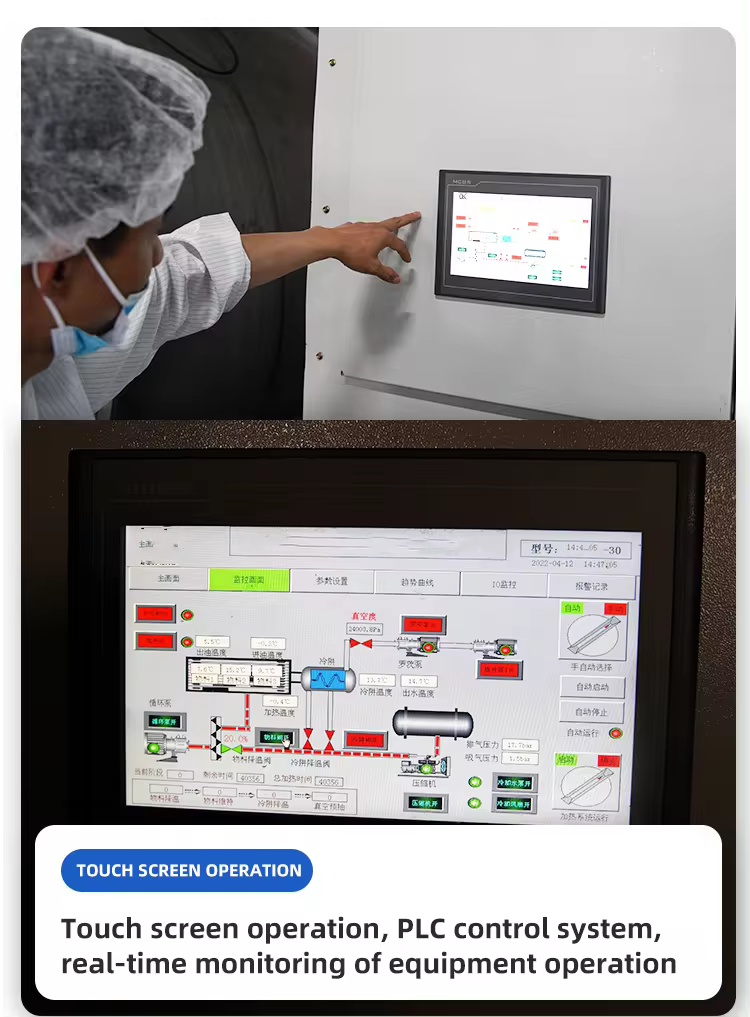

1. The continuous freeze-drying heating method adopts heat recovery refrigeration heating equipment to reduce boiler investment, and the

system adopts full automation, which is simple and fast.

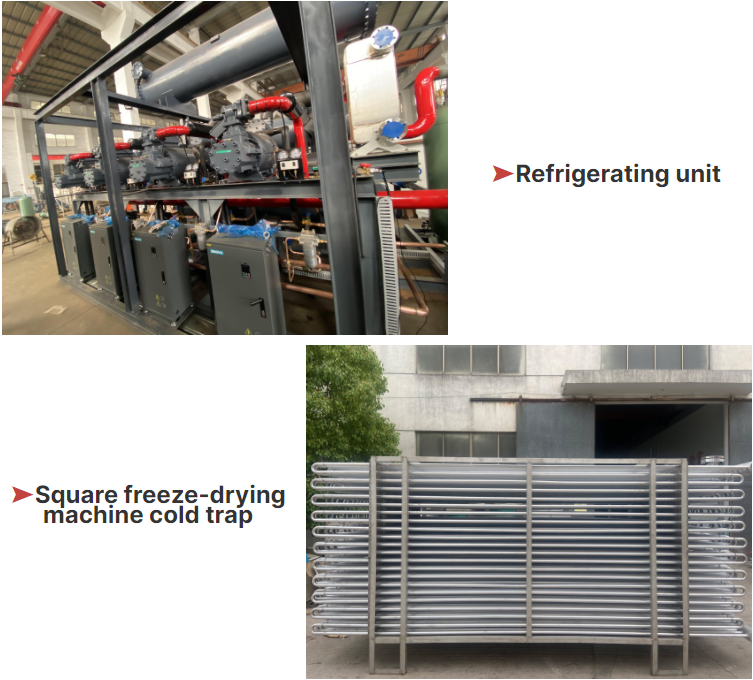

2. The refrigeration system adopts a single machine dual stage, with a large refrigeration capacity and low input power. The refrigeration

capacity can be automatically adjusted according to the load.

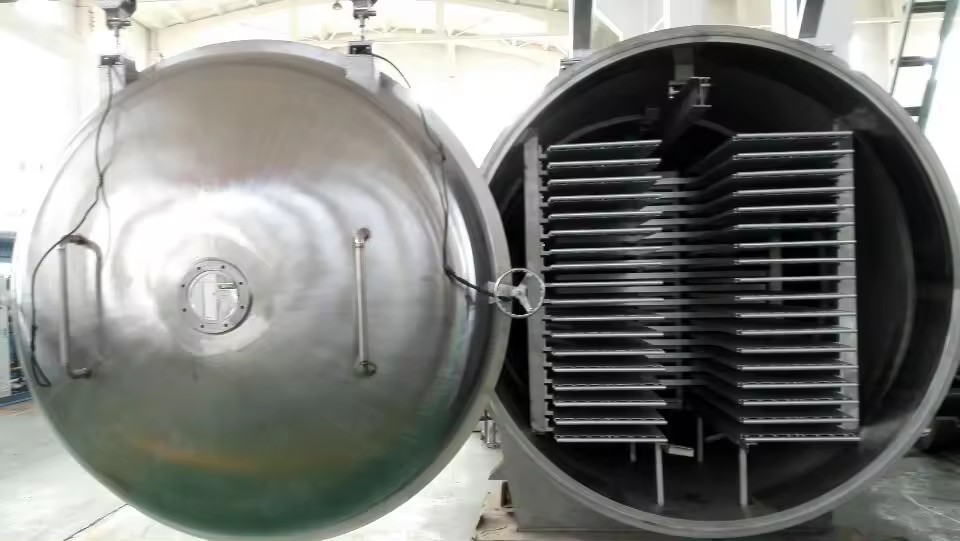

3. Continuous production adopts a rectangular or circular warehouse structure, with isolation vacuum locks at both ends. The main warehouse

is equipped with a track walking system, multiple heating temperature bands, and an automatic temperature control system, which can

accurately judge the degree of material drying.

4. Continuous production adopts multiple external cold trap devices and built-in ones, and is equipped with automatic ice melting and cooling.The ice melting and cooling are carried out step by step according to the production situation, and the cold load can be intelligently controlled according to the refrigeration load.

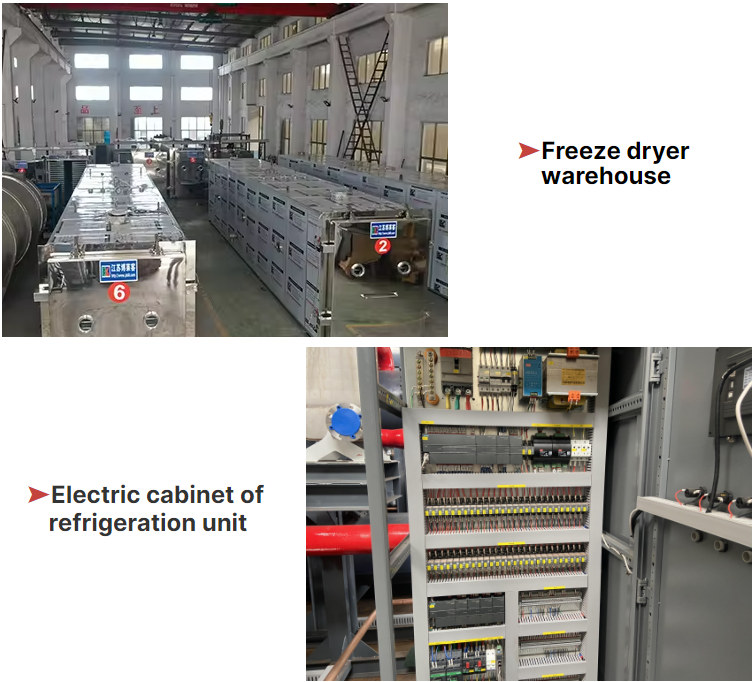

Machine Details :

Customer site pot:

Welcome Your Inquiry!