Air Energy Saving Potato Dryer Machine Coconut Drying Machine Mango Drying Equipment

Description:

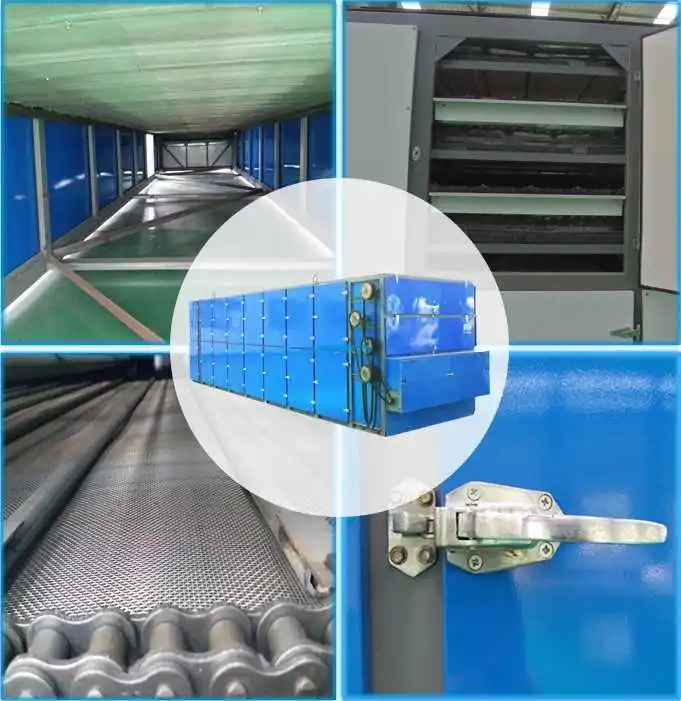

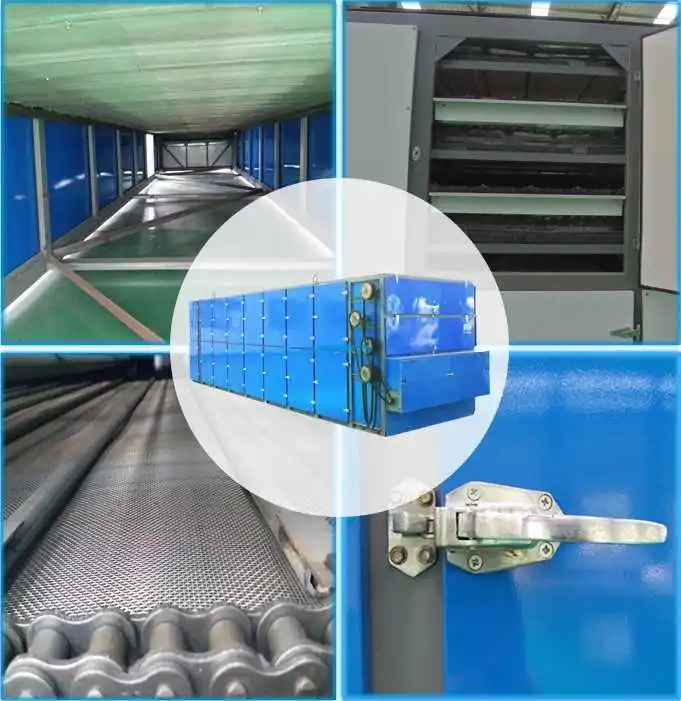

The dryer is a dynamic-drying multi-layer mesh belt dryer.

The mesh belt dryer through the air supply system to the air according to the material drying process requirements into the drying room.

At the same time, the material through the automatic laying device, cleaning machine, slicing machine, lifting machine into the drying room, and in the drying room along the horizontal direction to do section rotation, do "S" shaped operation, while the hot air vertically through the material, high heat transfer efficiency, so as to achieve the purpose of drying material pieces.

A heat pump dryer is a device that transports heat:

Total heat of transportation=input electrical energy (compressor power)the at transferred from air energy;So the heat pump dryer has broken the law that the electrical thermal efficiency does not exceed 100%. The annual average energy efficiency ratio of the air energy high-temperature heat pump dryer is about 300%, the annual average energy efficiency ratio of the air energy heat pump dehumidification dryer is about 350%, and the annual average energy efficiency ratio of the air energy heat pump drying cold storage unit is about 600%.

1.Highly automated, large capacity and energy saving;

2.User frinedly,1-2works needed;

3.Temparature adjusted to best preserve the nutrition;

4.Specialized devvice to spread materials evenly so as to shorten the drying cycle and reduce processing cost.

5. Mutible choices of heating source; such as coal, biomass fuel, natural gas, hot blast stove, steam heat exchanger, air energy heat pump, etc.

Put the wet material on feeding device, The material through the homogenizer was spread evenly and entered from the top of the dryer;

The material is transported by multi-layer mesh belt from top layer to bottom layer in the oven;

At the same time,the resource produce heat and come into the oven from the bottom;

After heat exchange, the moisture is evaporated from the top, and the material is discharged from the outlet after drying.

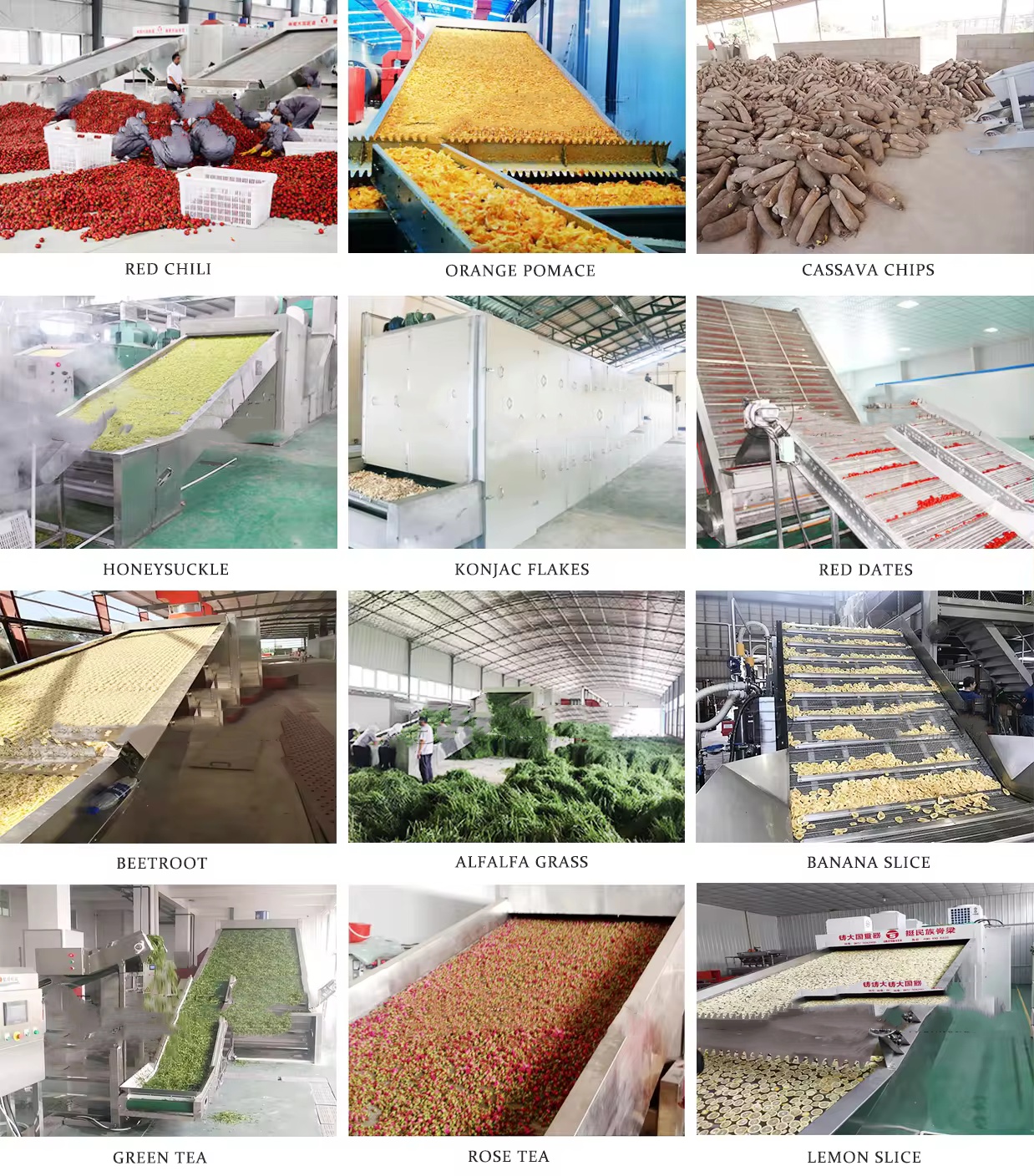

Application:

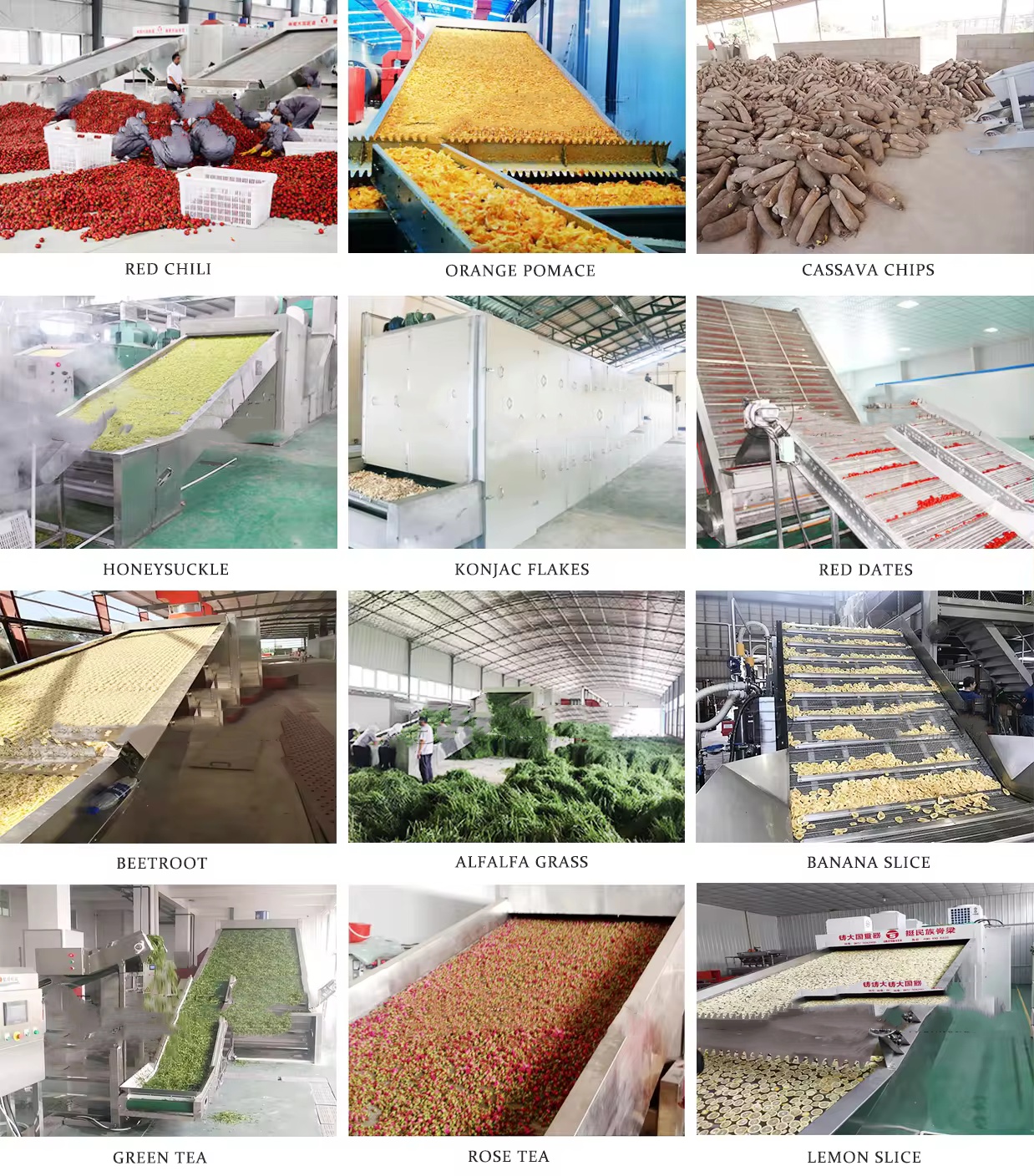

Our Cassava Drying Machine is suitable for drying every surface of raw material,such as dehydrated vegetable,Petal,grain,herbal industry,spice and so on.After drying,the original color, shape, and nutrient content can be retained completely by the dried material.

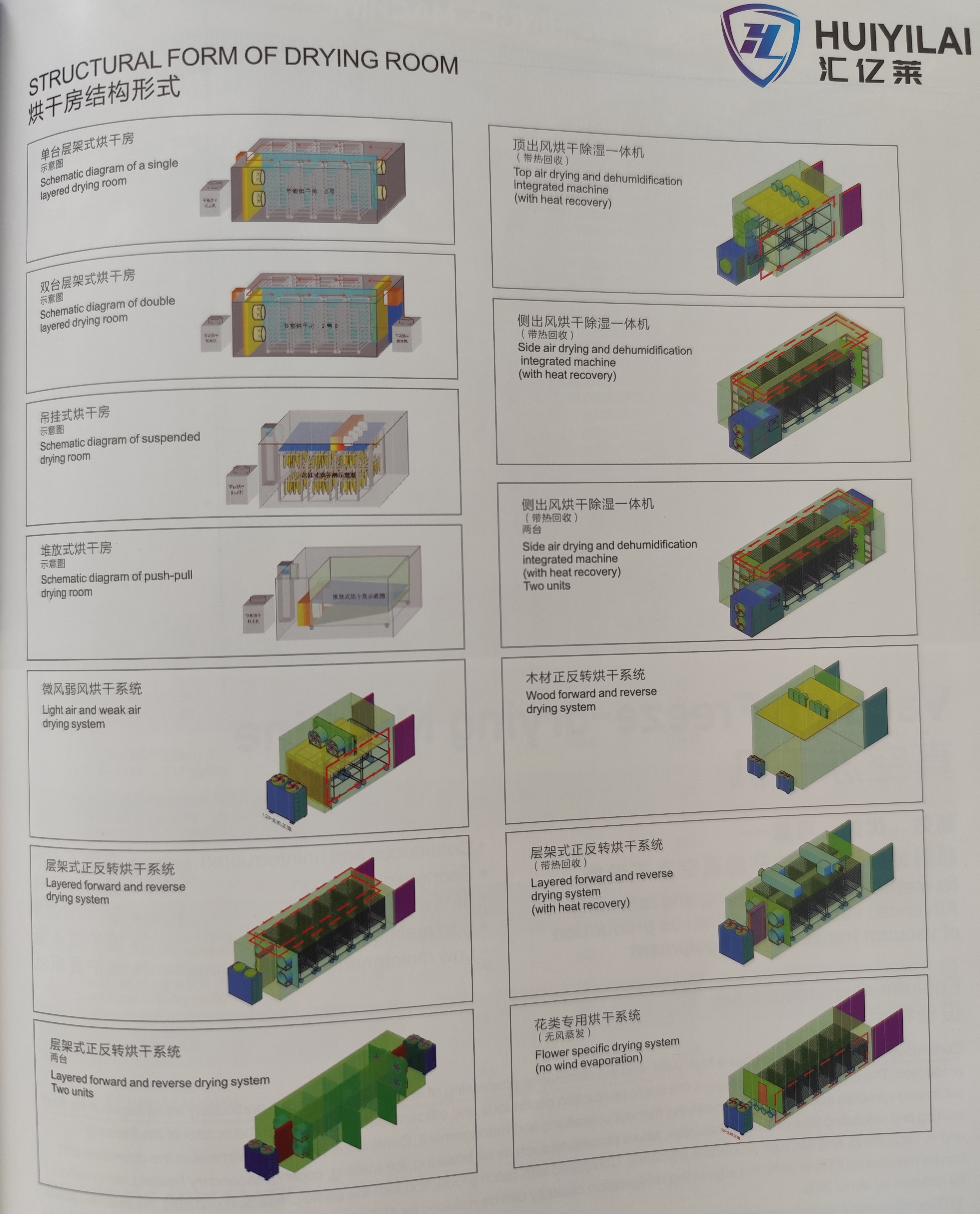

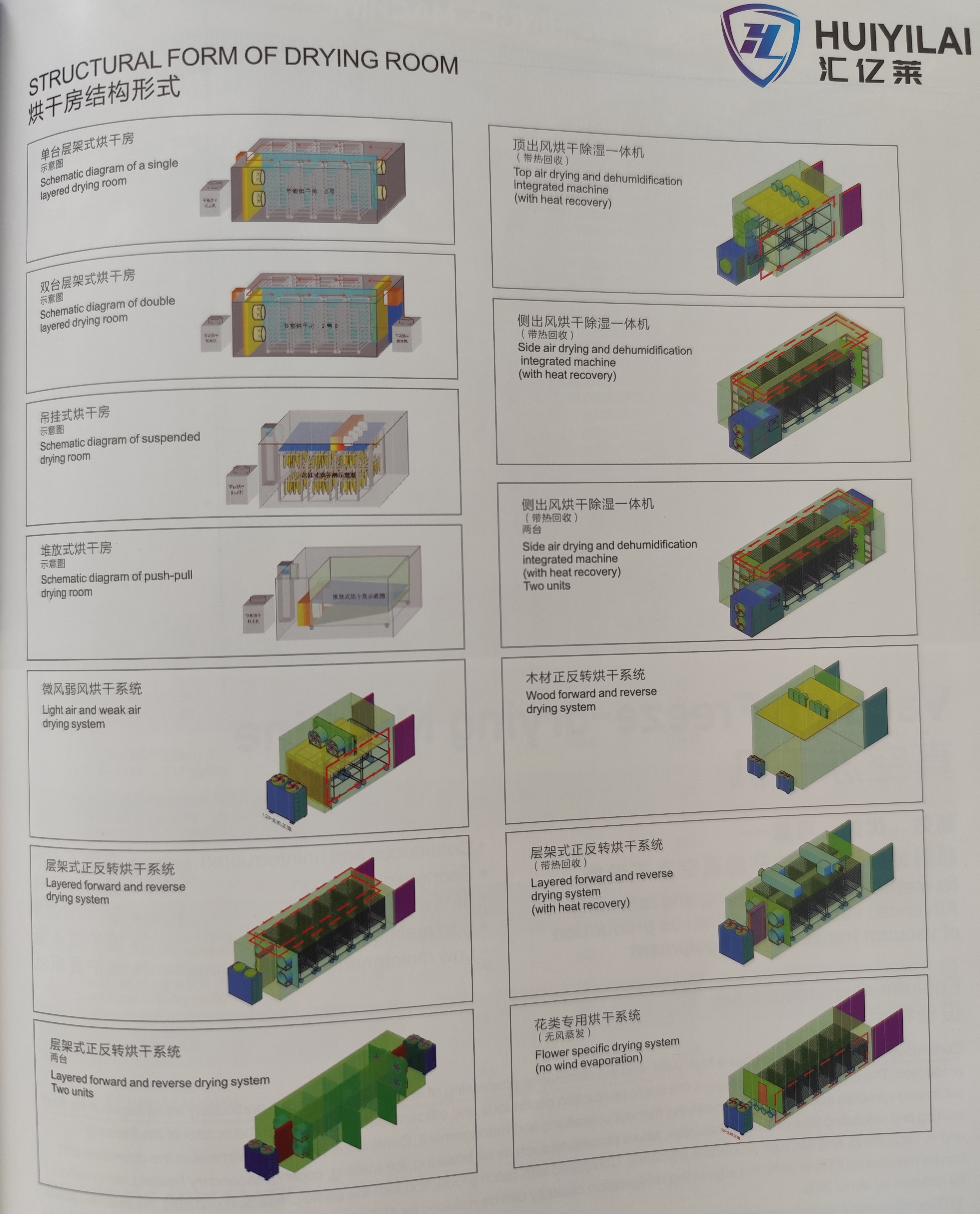

Different Structural Form of Drying Room according to different customer drying demand:

Customers Site Show:

We support different dryer structure for different customer demand timly and professional.