Product Overview

The commercial fruit vegetable dry machine (also called mango tray dehydrator or cinnamon drying oven) is a high-performance drying equipment designed for large-scale food and industrial material dehydration. Powered by a high-temperature circulating fan, it uses forced hot air circulation to accelerate water evaporation, ensuring uniform drying and nutrient preservation. Made of food grade SS304 stainless steel, the fully enclosed structure minimizes heat loss, making it energy-efficient and suitable for diverse industries.

Key Features

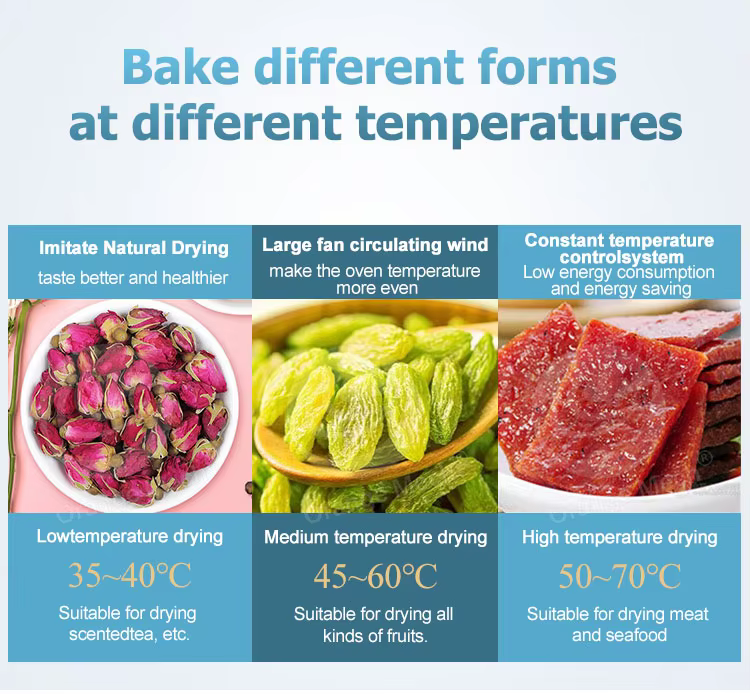

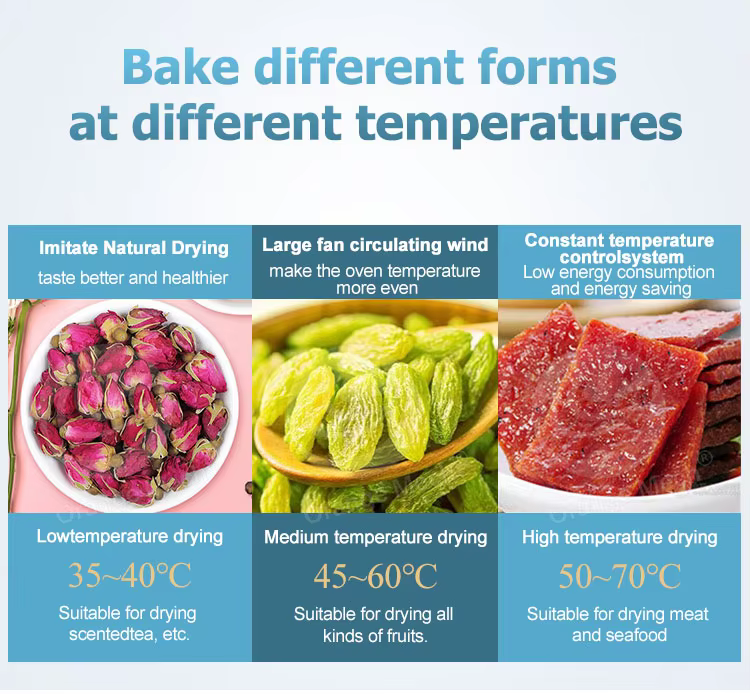

Precise Temperature Control & Nutrition Preservation

The machine offers adjustable temperature ranges (3540°C for low-temperature drying, 4560°C for medium-temperature, 50~70°C for high-temperature), allowing optimal drying conditions for different materials. The constant temperature control system preserves the nutrition, color, and flavor of food, imitating natural drying for healthier results.

Uniform Hot Air Circulation

Equipped with a large circulating fan and layered air flow system, the dryer distributes hot air evenly across all trays. This ensures consistent drying of materials, avoiding over-drying or under-drying and shortening the overall drying cycle.

Multifunctional Heating Source Options

Users can choose from multiple heating sources, including coal, biomass fuel, natural gas, hot blast stove, steam heat exchanger, and air energy heat pump. This flexibility adapts to different energy supplies and cost requirements.

Large-Capacity & Continuous Operation

The double-door design enables large-capacity drying and continuous operation, supporting high-volume production needs. The stainless steel tray structure is durable and easy to load/unload, enhancing workflow efficiency.

Energy-Saving & Low-Consumption Design

The fully enclosed box structure reduces heat loss, while the dehumidification fan accelerates moisture removal without wasting energy. The machine’s high automation level minimizes labor input, further lowering operational costs.

Technical Specifications

Parameter | Details |

Material | Food grade SS304 stainless steel (body) |

Model | HYL OEM |

Heating Methods | Coal, biomass fuel, natural gas, hot blast stove, steam heat exchanger, air energy heat pump |

Temperature Range | 35~70°C (adjustable) |

Temperature Control | Constant temperature control system |

Capacity | Customizable according to customer needs |

Fan Type | High-temperature circulating fan |

Structure Design | Fully enclosed, double-door, layered tray design |

Control Mode | PLC control panel (automatic operation) |

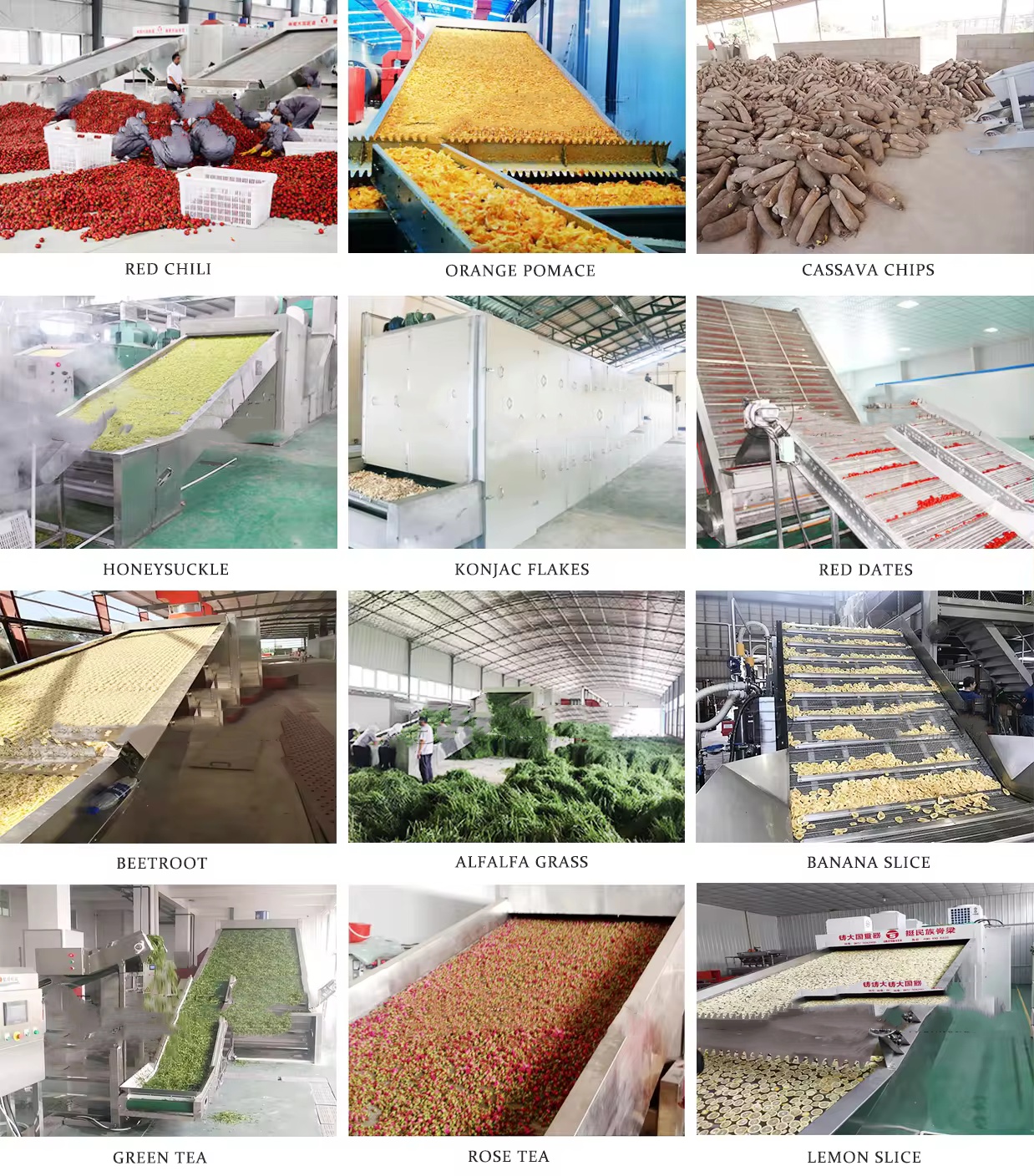

Application Areas

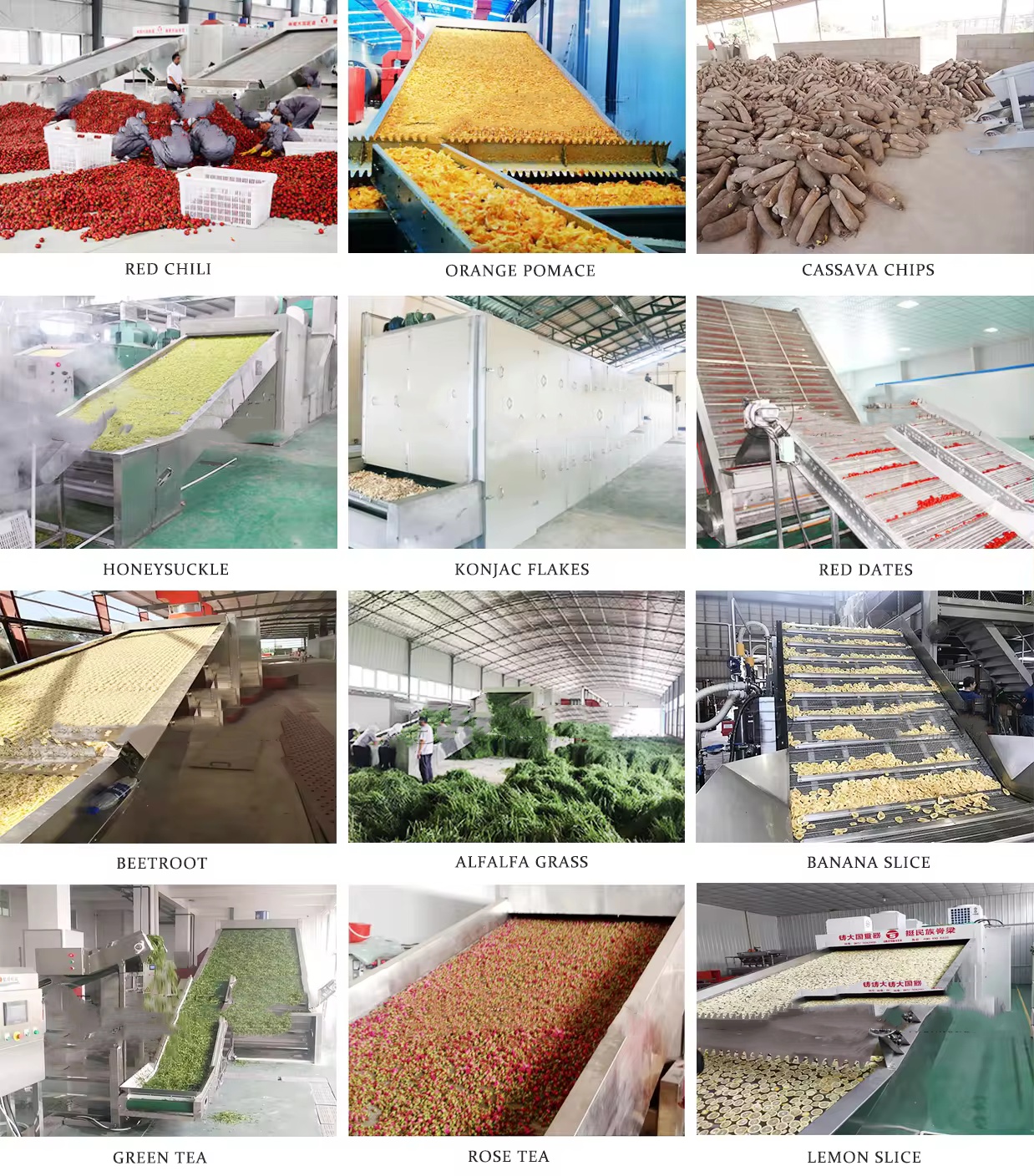

Food Industry

Widely used for drying fruits (mango slices, banana slices, lemon slices, red dates), vegetables (red chili, beetroot, cassava chips), seafood (dried fish, shrimp), pet food (jerky), and tea (green tea, rose tea, honeysuckle). It is also suitable for dehydrating herbs, spices, and processed food products.

Chemical & Agricultural Industries

Applicable to drying grains, fertilizers, feeds, and chemical raw materials, supporting light and heavy industries with efficient material dehydration needs.

Operation & Safety

Intuitive PLC Control

The PLC control panel features simple and clear operation, allowing users to set temperature, drying time, and air flow parameters with ease. The high automation level requires only 1-2 operators for daily operation.

Safety & Hygiene

The stainless steel door handle and safety lock ensure safe operation, preventing accidental door opening during drying. The SS304 material is non-toxic, corrosion-resistant, and easy to clean, complying with food hygiene standards.

Durable & Low-Maintenance

The thickened stainless steel structure ensures stability and long service life. Routine maintenance involves cleaning the fan and trays, with detailed guidelines provided in the user manual.

Customization Support

We provide personalized customization to meet specific production needs:

Custom machine size and tray quantity for different capacity requirements.

Selection of heating sources based on local energy availability and cost.

Adjustment of tray size and spacing for special-shaped materials.

Modification of temperature range and air flow for specialized drying needs.