Overview

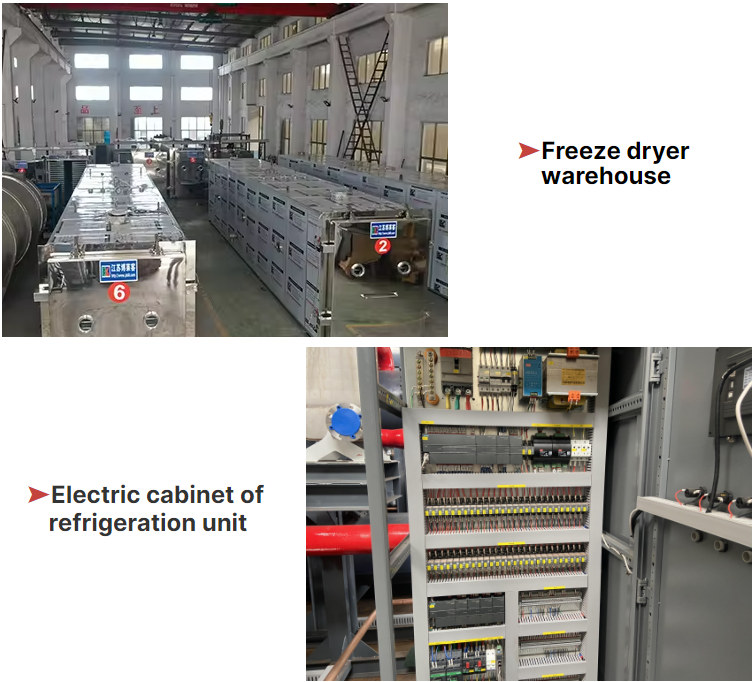

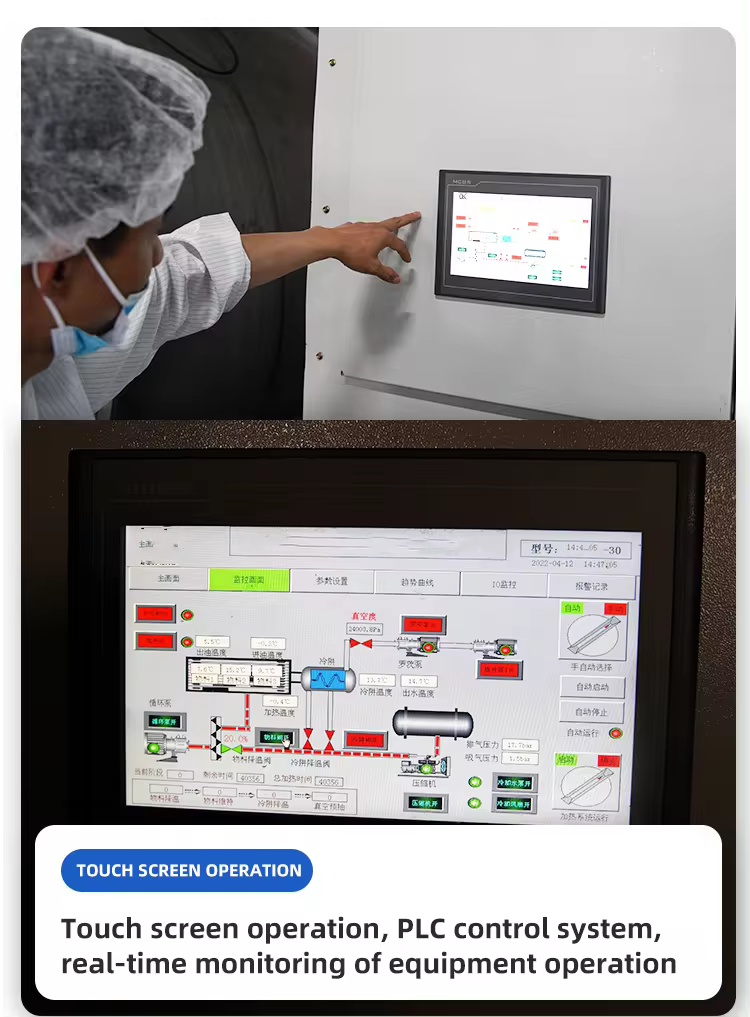

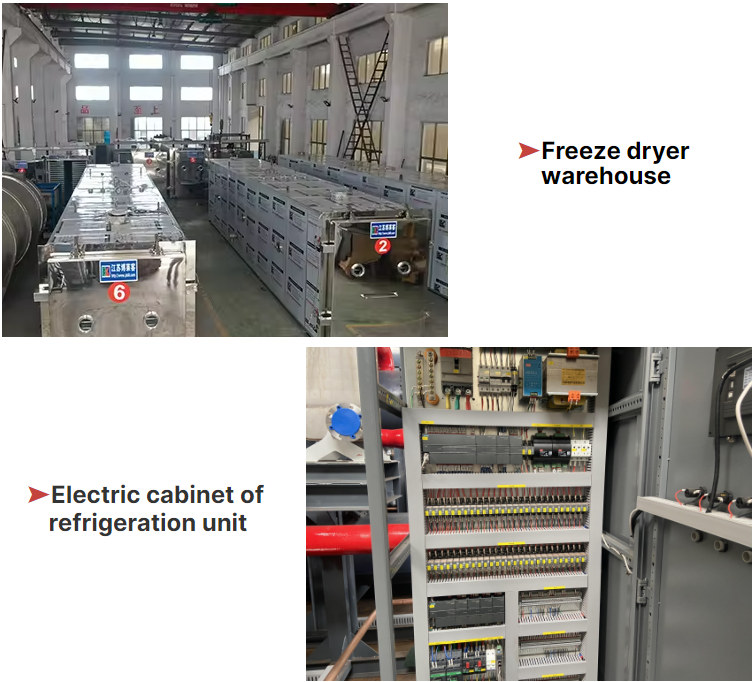

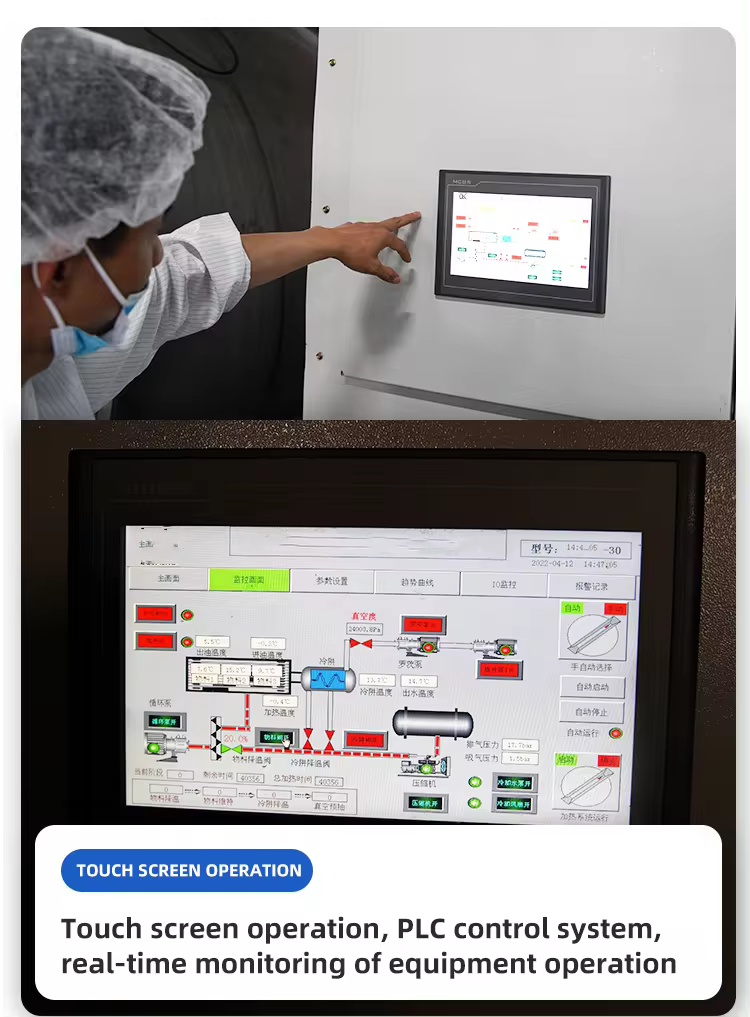

The Industrial Large scale Vacuum Fruit Food Freeze Dryer transforms fresh produce into lightweight, shelf-stable ingredients through a three-stage process: freezing, primary drying, and secondary drying. With a 500-2000L chamber capacity, it removes over 98% of moisture while preserving color, flavor, and nutrients, making it essential for processing berries, herbs, and ready-to-eat meals. The fully automated system features PLC control and real-time data logging, ensuring consistent quality across large batches.

Features

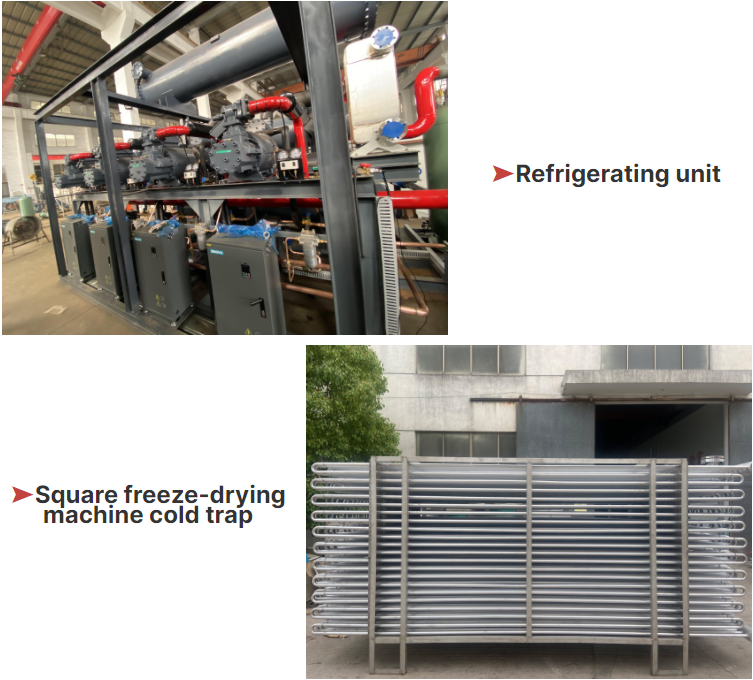

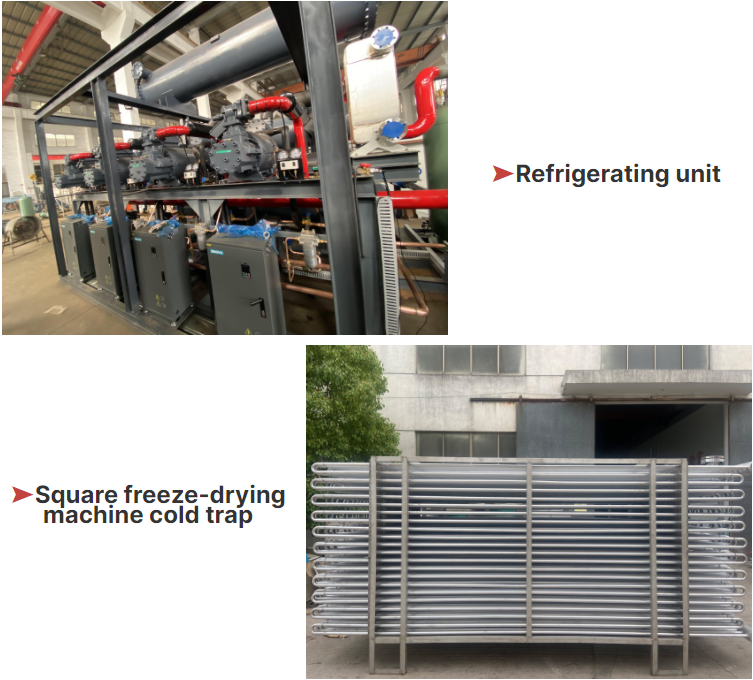

Cryogenic Freezing System: Pre-freezes products to -50°C using dual-stage refrigeration (CFC-free), forming uniform ice crystals to enhance sublimation efficiency.

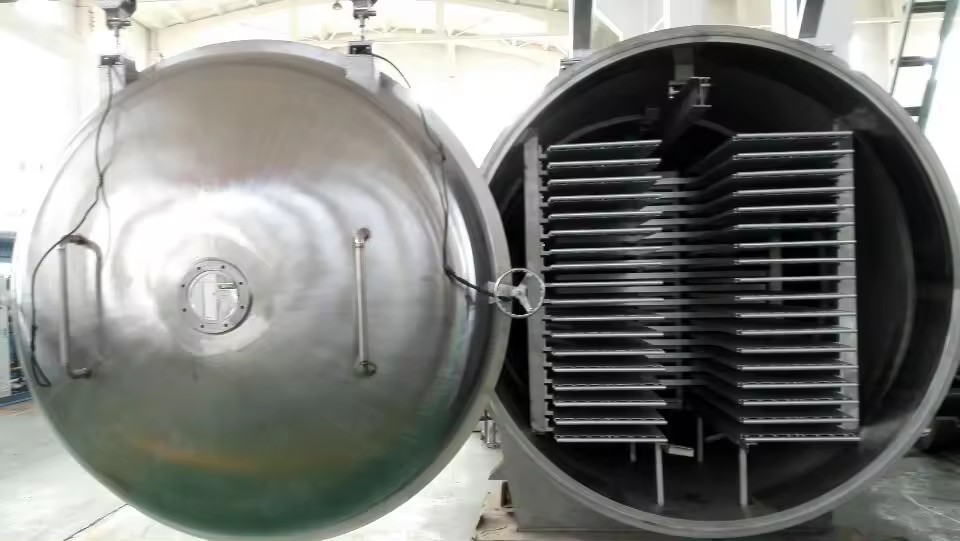

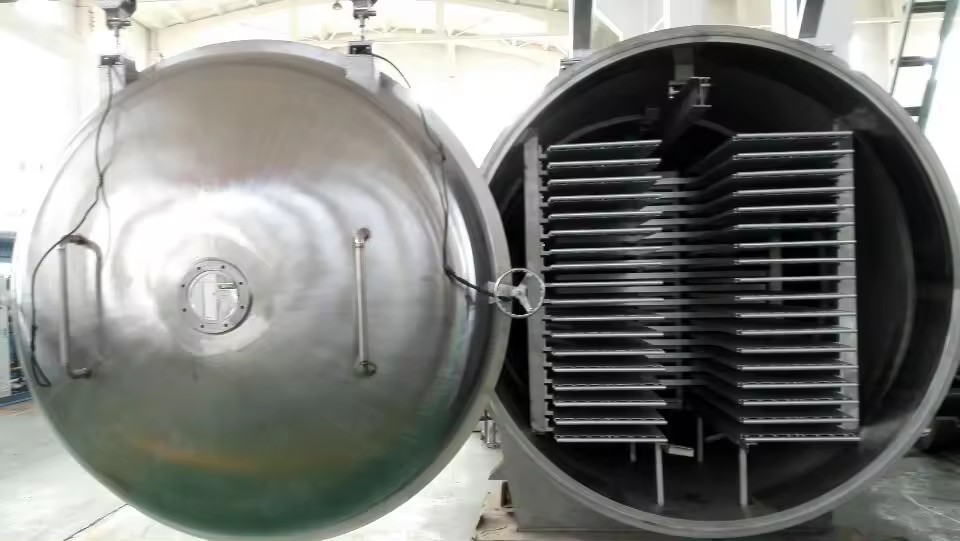

High-Vacuum Drying Chamber: Stainless steel chamber (316L) with horizontal shelves (heated to +70°C) and vertical condenser ( -80°C), achieving drying rates of 15-25kg/h (water removal).

Energy Recovery Technology: Recycles 60% of waste heat from the condenser to pre-heat incoming air, reducing electricity consumption by 30% compared to standard models.

Sanitary Design: All contact surfaces polished to Ra≤0.8μm, with CIP/SIP capabilities (steam sterilization up to 135°C) for pharmaceutical-grade hygiene.

Remote Monitoring: IoT-enabled HMI allows real-time tracking of pressure, temperature, and moisture content via smartphone/PC, with automatic alarms for process deviations.

Application

Food Ingredients: Produces premium freeze-dried fruits (strawberries, mangoes), vegetables (spinach, mushrooms), and herbs for use in snacks, soups, and dietary supplements.

Medical & Aerospace: Processes biological samples, pharmaceuticals, and astronaut food requiring long-term stability without refrigeration.

Pet Food: Creates high-protein treats (freeze-dried chicken, liver) with natural flavor retention, appealing to health-conscious pet owners.

Emergency Rations: Ideal for military and disaster relief supplies, providing lightweight, nutrient-dense meals with 2+ year shelf life.

FAQ

Q: What is the typical drying time for a full load?

A: 24-48 hours depending on product type and moisture content (e.g., 36 hours for strawberries, initial moisture 90% to final 2%).

Q: Can liquid products (e.g., soups) be freeze-dried?

A: Yes, using tray inserts for pre-freezing liquids into blocks before drying, with optional milling systems for powdered end products.

Q: How often does the vacuum pump oil need change?

A: Recommended every 1000 operating hours or quarterly, with oil level sensors prompting maintenance alerts.

Model | HYLXFD-200 | HYLXFD-300 | HYLXFD-500 | HYLXFD-600 | HYLXFD-900 | HYLXFD-1200 |

Feed rate of extraction solution containing 45% dry matter (kg/h) | 474 | 711 | 1185 | 1423 | 1897 | 12845 |

Capacity(kg) | 220 | 330 | 544 | 660 | 872 | 1320 |

24 hours output (kg/day) | 5280 | 7920 | 13066 | 15840 | 20928 | 31680 |

Feed rate of extraction solution containing 25% dry matter (kg/h) | 313 | 469 | 780 | 937 | 1249 | 1874 |

Capacity(kg) | 81 | 121 | 201 | 241 | 322 | 482 |

24 hours output (kg/day) | 1933 | 2900 | 4826 | 5800 | 7728 | 11600 |

Feed rate of extraction solution containing 15% dry matter (kg/h) | 170 | 256 | 427 | 512 | 684 | 1022 |

Capacity(kg) | 26 | 40 | 65 | 79 | 105 | 158 |

24 hours output (kg/day) | 632 | 948 | 1573 | 1896 | 2520 | 3792 |

Freezing temperature | -30℃~-60℃(Can design) |

Condenser temperature | -50℃~-80℃(Can design) |

Heating way | Silicone oil ,Electric heating |

Vacuum degree | ≥1Pa |

Remark: Here also Can produce vacuum freeze-drying machines ranging from 5kg to 3000kg according to customer requirements |