Product Overview

The Dynamic Multi-Layer Mesh Belt Dryer is a highly efficient drying solution designed to handle a wide range of materials in various industries. Utilizing advanced heat pump technology, this dryer optimizes energy consumption and enhances drying efficiency. The dryer features a multi-layer mesh belt system that facilitates consistent and effective drying of materials through a combination of horizontal rotation and vertical hot air flow. This design ensures high heat transfer efficiency, making it an ideal choice for drying material pieces quickly and effectively.

The heat pump dryer operates by transferring heat from the air using a specialized system that increases the energy efficiency of the drying process. With an annual average energy efficiency ratio (EER) of up to 600%, it offers substantial savings on energy consumption, making it an environmentally friendly and cost-effective solution for businesses.

Key Features and Advantages

1. High-Efficiency Heat Pump Technology

The heat pump dryer uses air to transfer heat, achieving an impressive energy efficiency ratio. The heat pump's annual average EER ranges from 300% to 600%, significantly reducing energy consumption and operational costs compared to traditional drying methods.

2. International Brand Compressors

The dryer is equipped with high-quality, internationally recognized compressors, ensuring reliable and long-lasting performance. These compressors optimize the overall system’s efficiency, contributing to stable operations even at high temperatures.

3. Advanced PLC Control System

The dryer is controlled by a PLC control system, which has been independently developed and customized for specific drying requirements. Combined with Swiss-made high-temperature and humidity probes, this system allows for nine stages of control, including heating, cooling, dehumidification, and auxiliary heating. This customization ensures optimal drying conditions based on the material being processed.

4. Customizable Drying Programs

The dryer allows for customized drying programs, making it ideal for different materials. The system can be adjusted to meet the specific requirements of the materials being dried, ensuring maximum drying efficiency and quality.

5. Flexible Design for Different Drying Needs

6. Stable High-Temperature Operation

By using specialized snow seeds and high-temperature heat pump technology, the dryer operates stably even in high-temperature environments, making it suitable for a wide range of industrial applications.

7. Multi-Layer Mesh Belt with Efficient Drying Process

The multi-layer mesh belt ensures efficient material flow through the dryer, allowing hot air to pass vertically through the material. The materials move horizontally in a rotating "S" shaped path, ensuring even drying and high heat transfer efficiency.

Applications

The Dynamic Mesh Belt Dryer with Heat Pump is versatile and can be used in a variety of industries for drying different materials, such as:

Fruits: Apples, grapes, strawberries, peaches, etc.

Vegetables: Sweet potatoes, tomatoes, carrots, green beans, etc.

Nuts: Peanuts, jujube, etc.

Aquatic Products: Fish and seafood.

Livestock and Poultry: Meat drying applications.

Other Materials: For various manufacturing and production processes where drying is required.

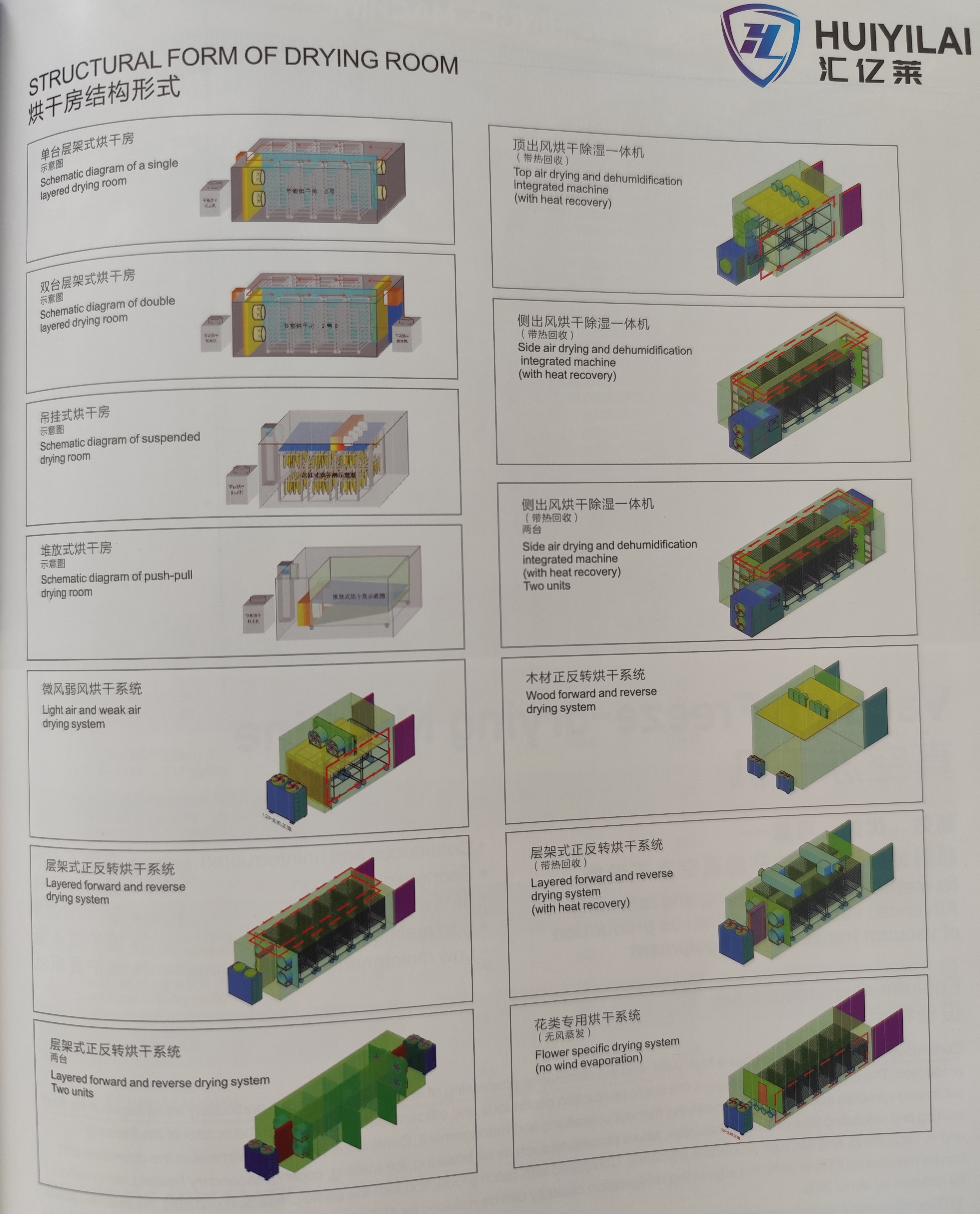

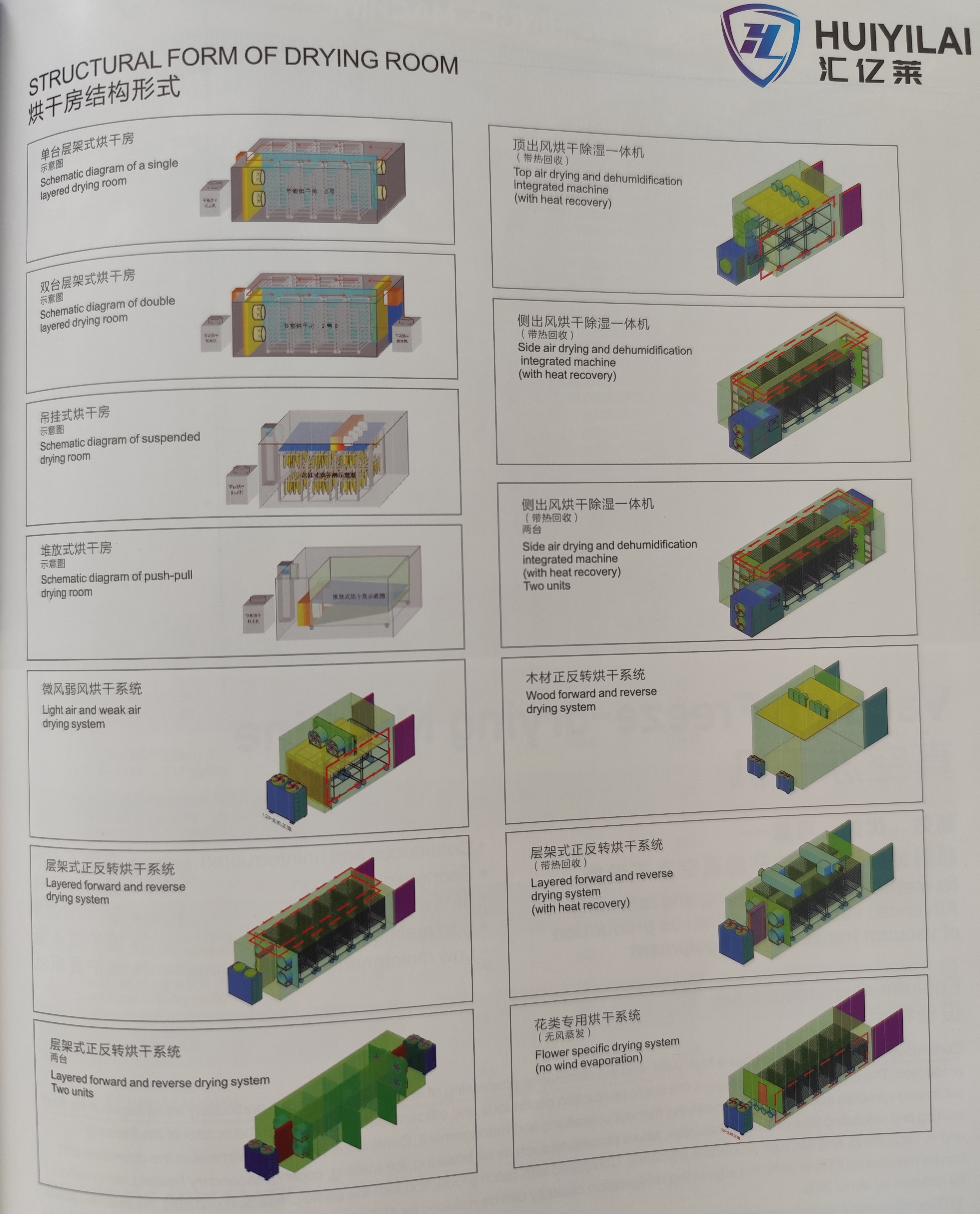

Different Structural Form of Drying Room according to different customer drying demand:

We support different dryer structure for different customer demand timly and professional.

Energy Efficiency & Environmental Benefits

The dryer’s heat pump technology sets it apart from traditional drying methods, offering the following benefits:

High energy efficiency: The dryer’s energy efficiency ratio (EER) can be as high as 600%, reducing energy costs and making it an eco-friendly solution for businesses.

Cost-effective operation: With low energy consumption and minimal waste, the dryer reduces operating costs, contributing to significant savings over time.

Environmentally friendly: The advanced heat pump technology ensures that the system uses air as the primary medium for heat transfer, making it a greener alternative to conventional dryers.

Why Choose the Dynamic Mesh Belt Dryer?

Superior Energy Efficiency: Save up to 60% on energy costs with high-efficiency heat pump technology.

Customizable Drying Programs: Tailor the drying process to suit different materials and applications.

Reliable Performance: Featuring top-brand compressors and PLC controls, the dryer offers consistent, long-term performance.

Versatile Applications: Perfect for a wide range of materials, from fruits and vegetables to meat and seafood.

Cost Savings: Achieve significant savings on operational costs, reducing both energy consumption and oil use.

Conclusion

The Dynamic Multi-Layer Mesh Belt Dryer with Heat Pump Technology is the perfect solution for businesses looking to optimize their drying processes while reducing energy consumption and operational costs. With its advanced heat pump technology, customizable drying programs, and versatile applications, this dryer ensures superior drying efficiency, making it a reliable and cost-effective choice for industries worldwide. If you’re looking for a high-performance dryer that is energy-efficient, customizable, and environmentally friendly, this is the ideal solution for you.