Industrial magna-scale vacuo fructum cibum Congelo Dryer ad Industrial Foeze Frigidus Dryer Processus Machina

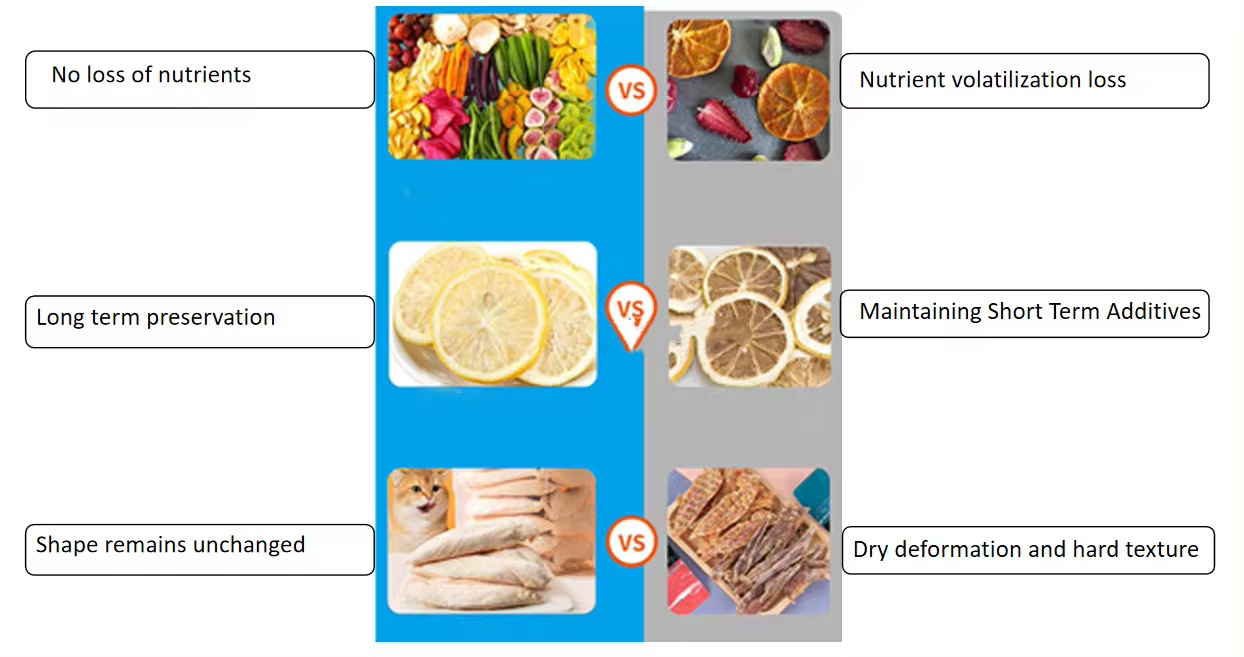

Quid elige vacuo congelat dryer?

Maximizing conservationem coloris, odorem et gustus cibis, ut custodiat naturalem pigmentis legumina immutata et obscurat damnum variis aromaticis substantiis; Dubi siccatio melius servare dapibus continet cibis quam iusto cryopreservation.

Technical parametri:

Exemplar | Hylxfd, CC | Hylxfd-CCC | Hylxfd-D | Hylxfd-DC | Hylxfd-CM | Hylxfd-MCC |

Pascere rate of extraction solution continet XLV% arida res (kg / h) | 474 | 711 | 1185 | 1423 | 1897 | 12845 |

Capacity (kg) | 220 | 330 | 544 | 660 | 872 | 1320 |

XXIV horas output (kg / die) | 5280 | 7920 | 13066 | 15840 | 20928 | 31680 |

Pascere rate of extraction solution continet XXV% arida materia (kg / h) | 313 | 469 | 780 | 937 | 1249 | 1874 |

Capacity (kg) | 81 | 121 | 201 | 241 | 322 | 482 |

XXIV horas output (kg / die) | 1933 | 2900 | 4826 | 5800 | 7728 | 11600 |

XV% arida Rate feed de solution ex solution (kg / h) | 170 | 256 | 427 | 512 | 684 | 1022 |

Capacity (kg) | 26 | 40 | 65 | 79 | 105 | 158 |

XXIV horas output (kg / die) | 632 | 948 | 1573 | 1896 | 2520 | 3792 |

Frigore temperatus | -30 ℃ ~ -60 ℃ (potest consilio) |

Condenser temperatus | -50 ℃ ~ -80 ℃ (potest consilio) |

Calefactio | Silicone oleum, electrica calefactio |

Vacuum gradu | ≥1pa |

Nark: Hic etiam potest producere vacuum Frigidus-siccatio machinis vndanging a 5kg ad 3000KG secundum Customer Requirements |

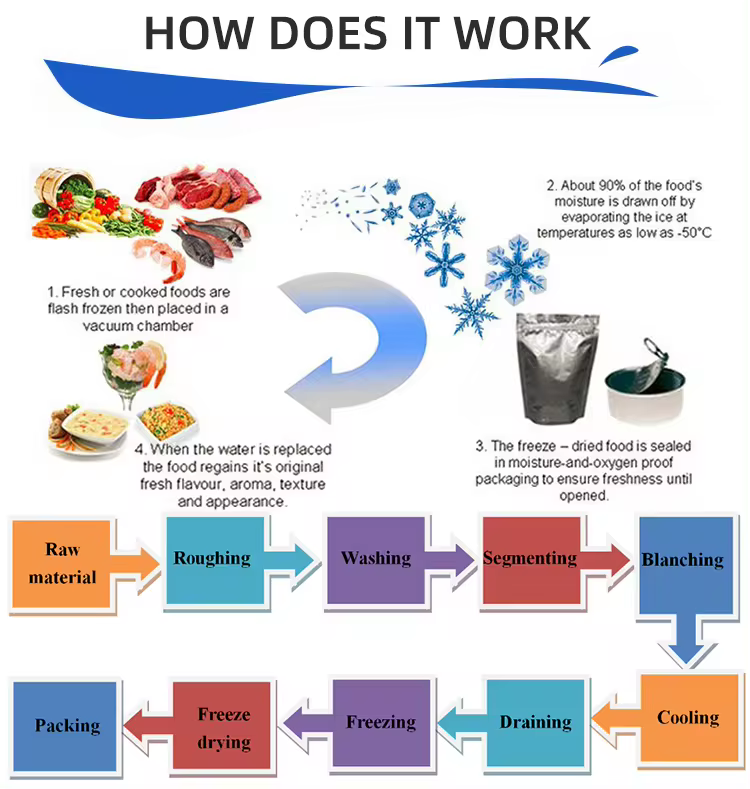

Equipment characteres:

Continua frigore-siccatio cibum habet princeps cedat et continua processui unius rudis materiae est praecipue utile cibum productio. Et apparatu non solum facit totam productio continua et efficient, sed etiam faciliorem imperium in frigore effigilibus subvolite processus et condiciones, simplifying operationes et administratione. Et continua productio elimintis downtime et loading et unloading tempus batch productio, salvet processibus ut aer fractionis, glacies liquescens, refrigerationem, secundarium calefacit, refrigerationem, et re vacuoing, et habet princeps productionem efficientiam. Comparari cum batch productio cum eadem productio facultatem, in installed potestatem potest reduci per XXI% ad XXX%, ad supporting refrigerationem facultatem potest reduci per CDIX% per circuitum XXV%.

I. De continua frigida-siccatio calefacit modum adoptat calor recuperatio refrigerationem calefactio apparatu ad redigendum boiler investment et

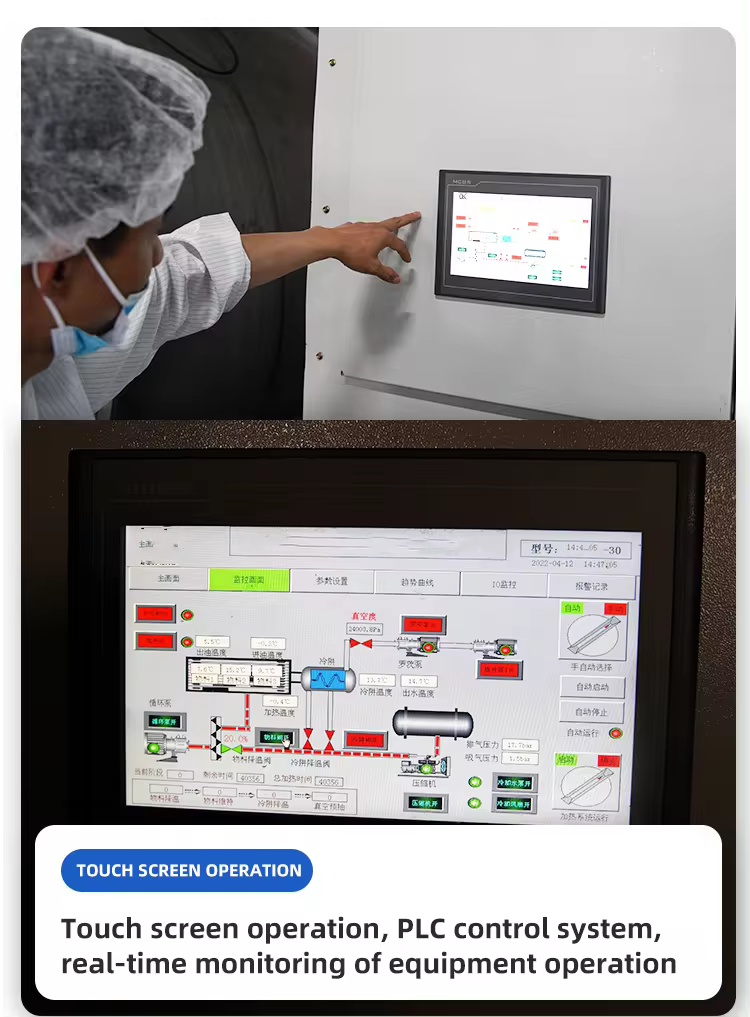

Ratio adoptat plena automation, quod est simplex et ieiunium.

II. Refrigeration systema adoptat unum apparatus dual scaena, cum magna refrigerationem facultatem et humilis initus potentia. Refrigeration

Capacitas potest esse automatically secundum ad onus.

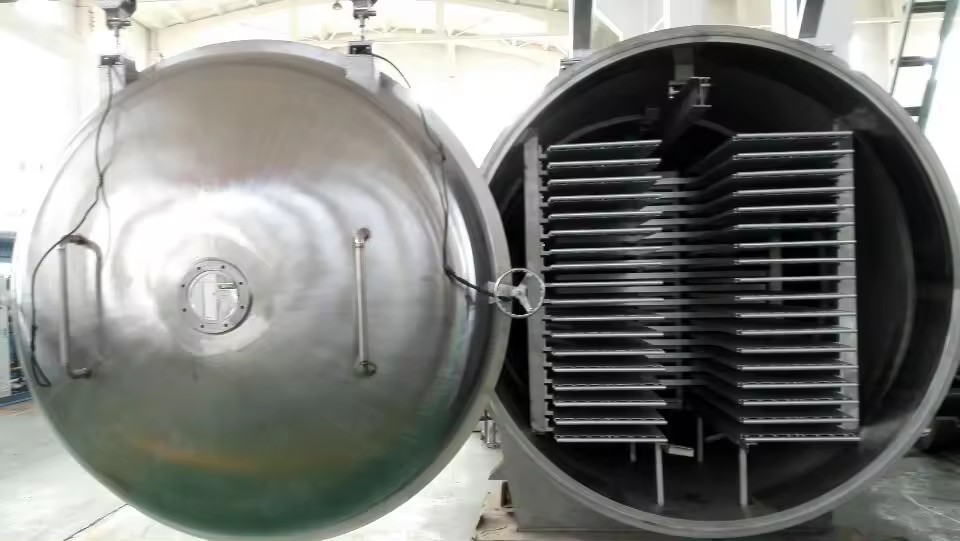

III. Continua productio rectangulum aut circularis CELLA structuram, cum solatio vacuo comis ad utrumque terminos. Pelagus CELLA

instructum est track ambulans ratio, multa calefactio temperatus vincula et automatic temperatus imperium system, quod can

verius iudicatur gradu de materia siccatio.

4. Continuous production adopts multiple external cold trap devices and built-in ones, and is equipped with automatic ice melting and cooling.The ice melting and cooling are carried out step by step according to the production situation, and the cold load can be intelligently controlled according to the refrigeration load.

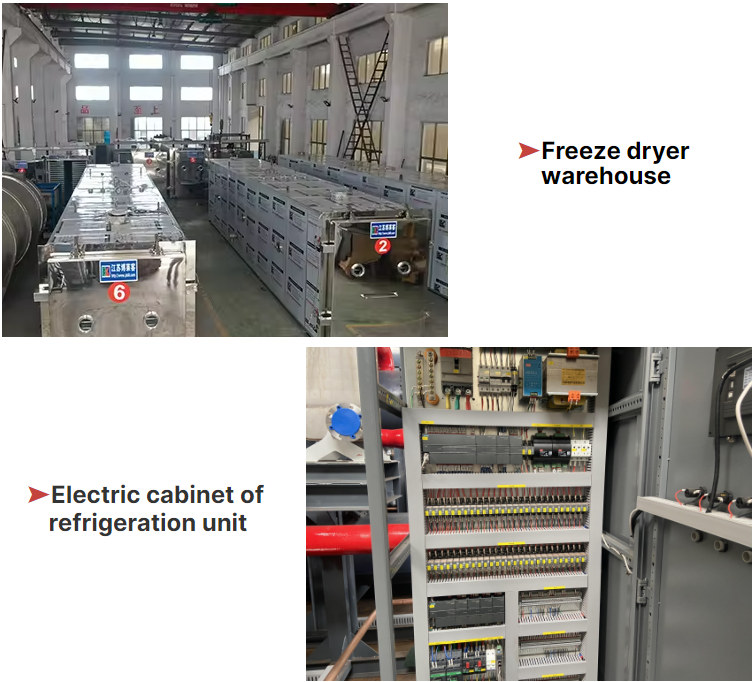

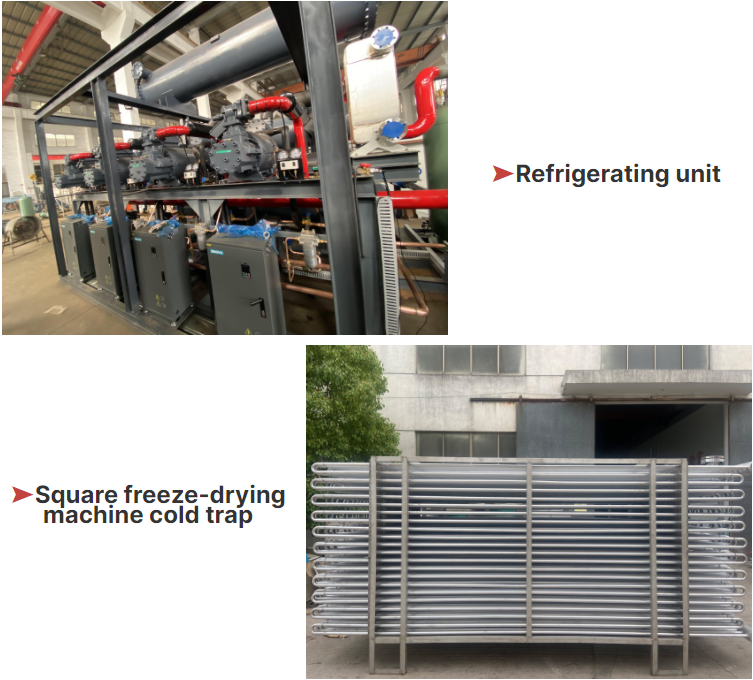

Machina Details:

Customer Site ollam:

Receperint tuum inquisitionis!