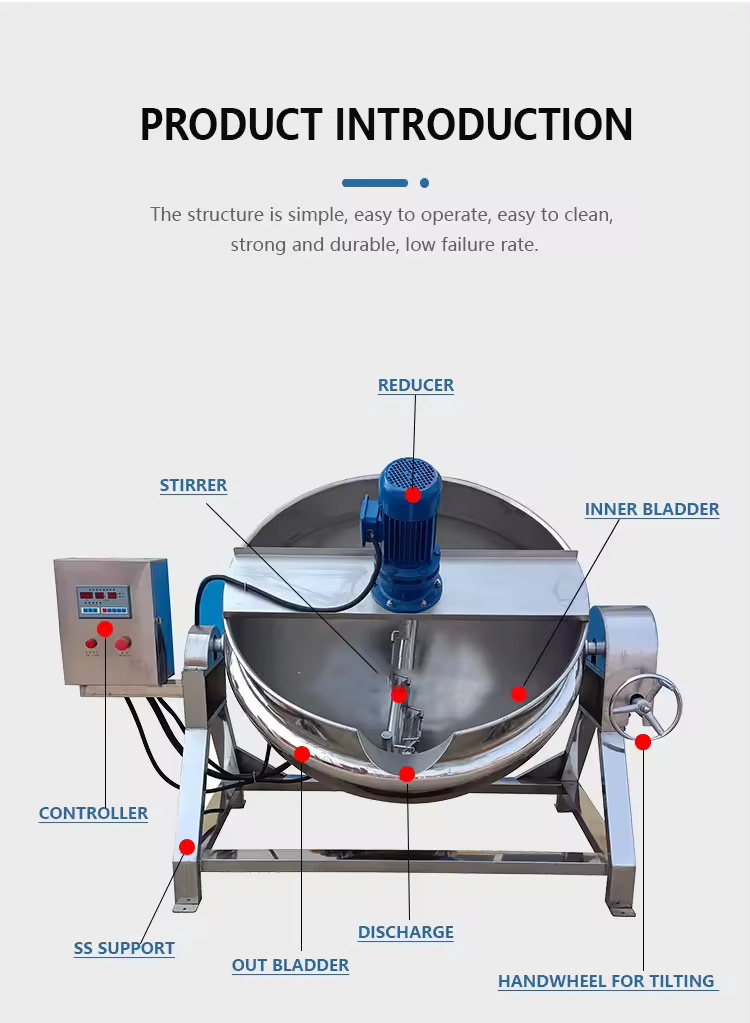

Product Overview

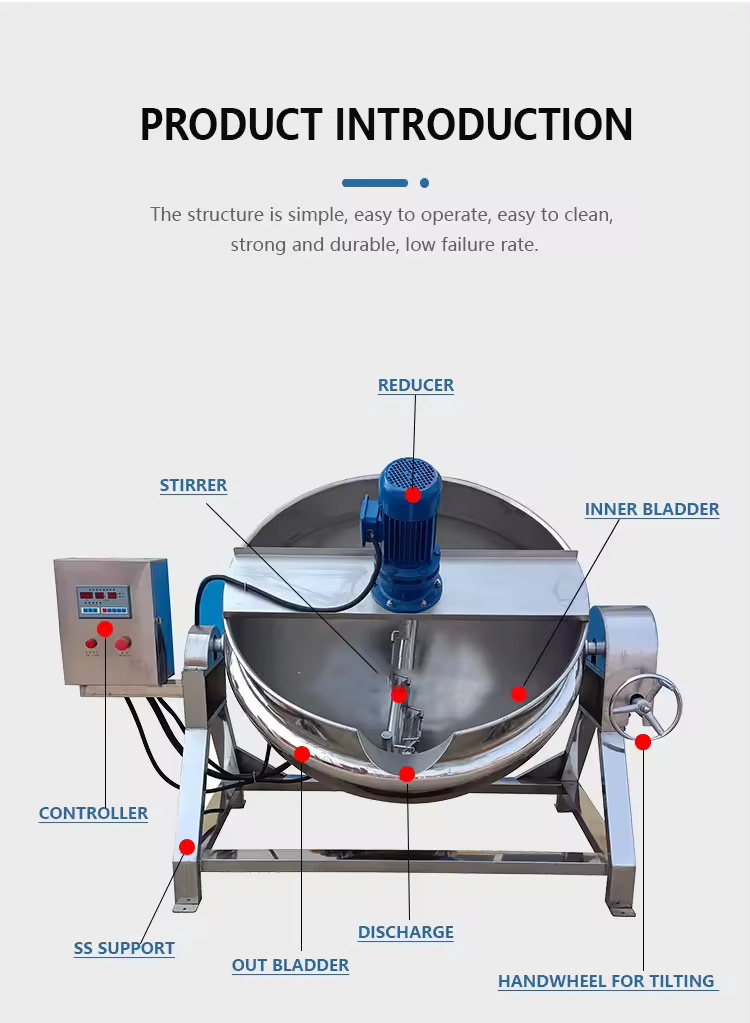

The 100-1000L Tilting Cooking Jacketed Kettle (also called Steam Jacketed Kettle or Electric Jacketed Kettle) is a versatile heating device by HUIYILAI for food processing. It features a double-layer spherical pot body—with a steam-heated interlayer between inner and outer layers—ensuring fast, uniform heating. Made of food-grade SS304, it meets food hygiene standards and comes in fixed, tilting, and stirring styles. The tilting design (up to 90 degrees) enables easy, residue-free discharge, making it essential for large-scale catering and food production.

Key Features

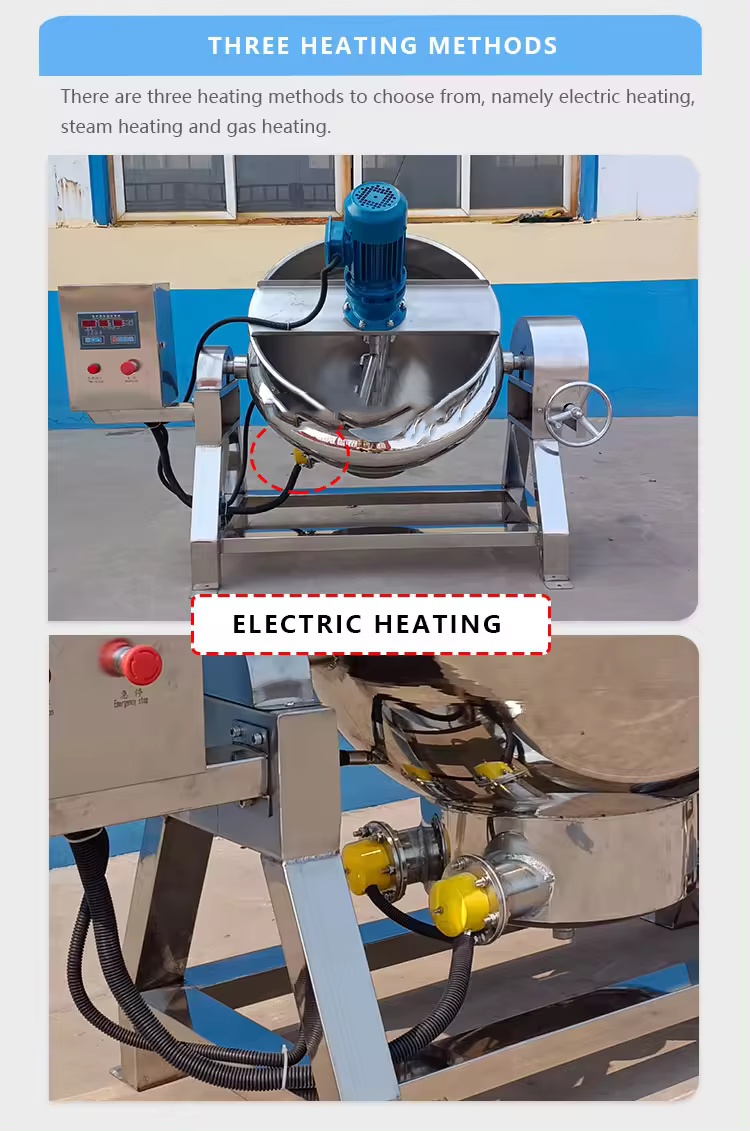

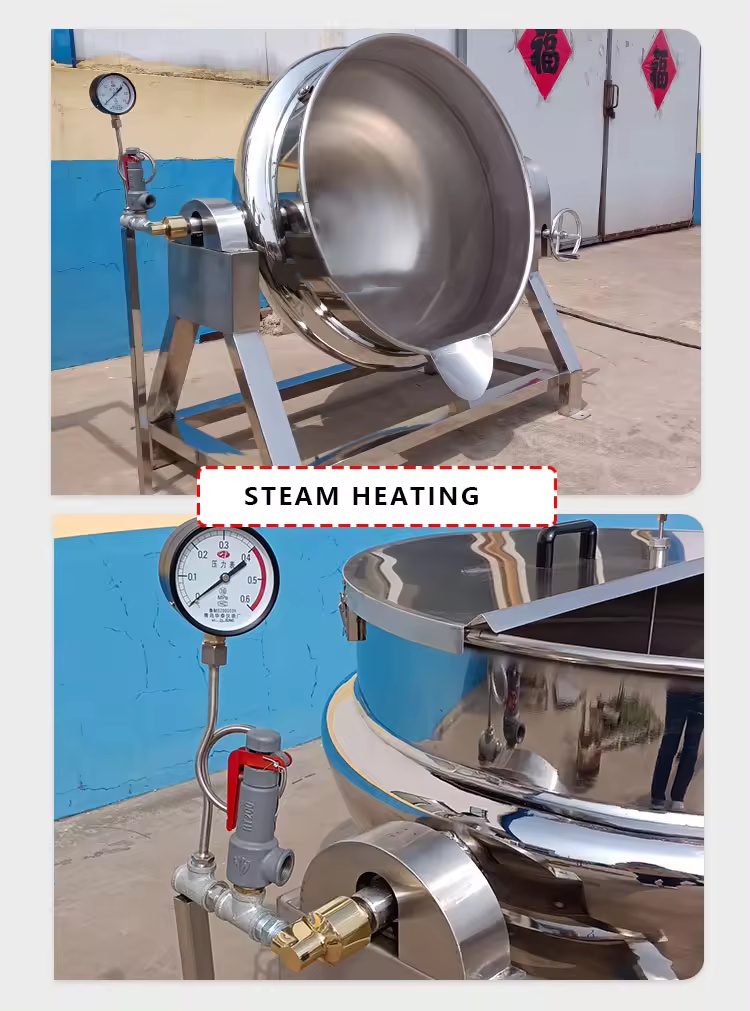

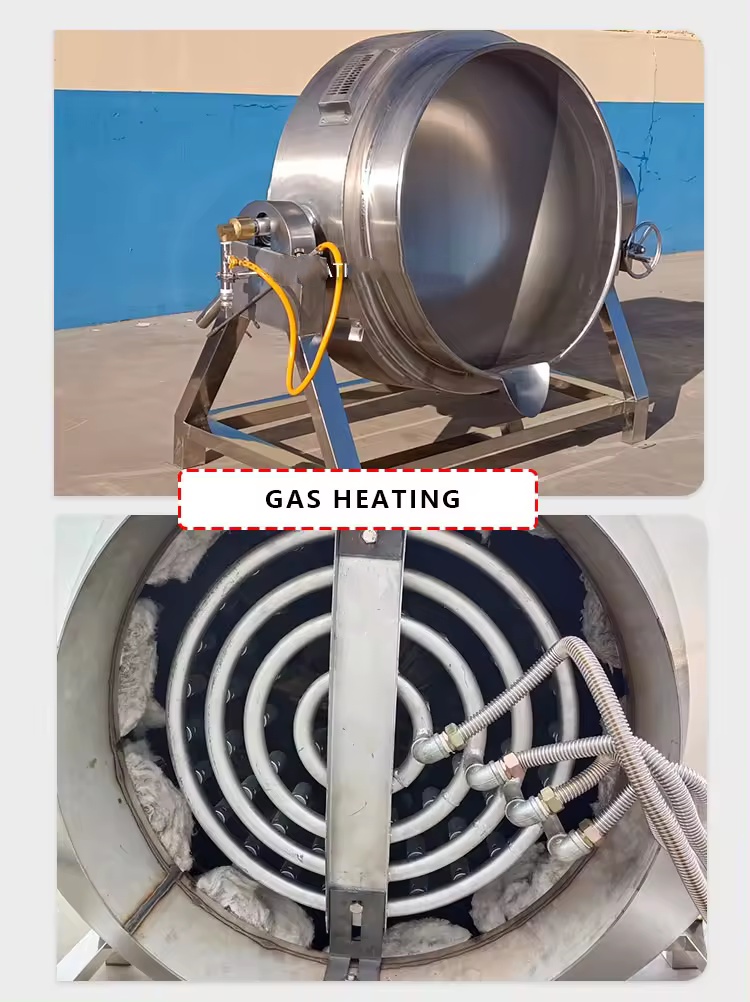

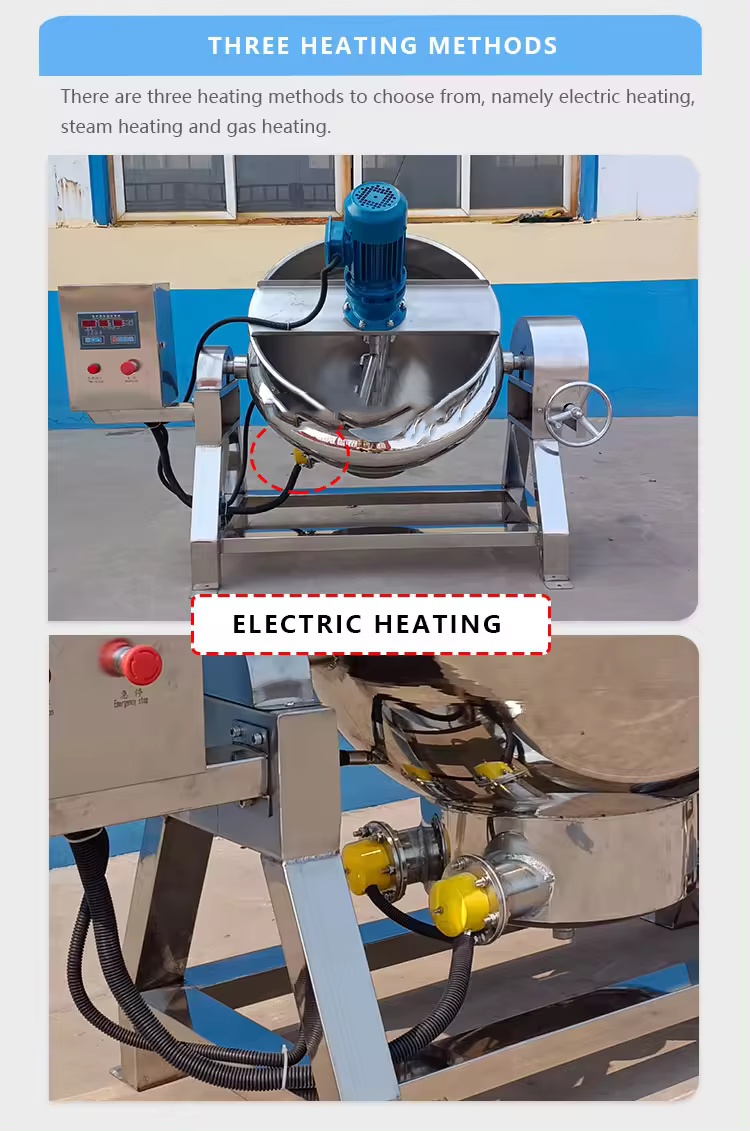

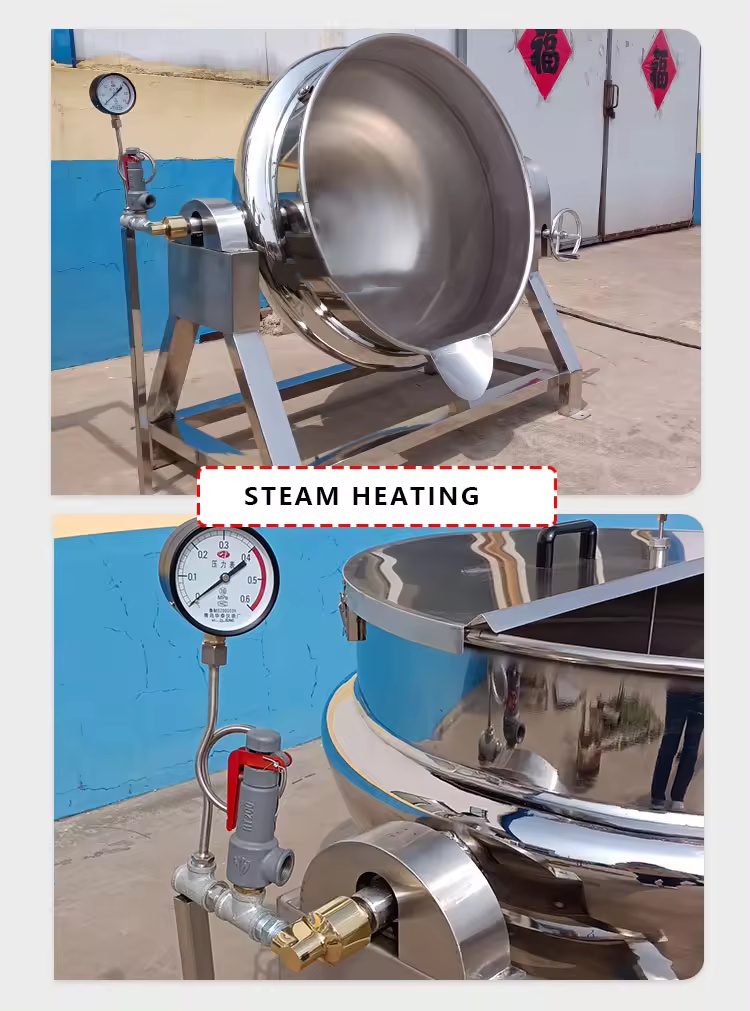

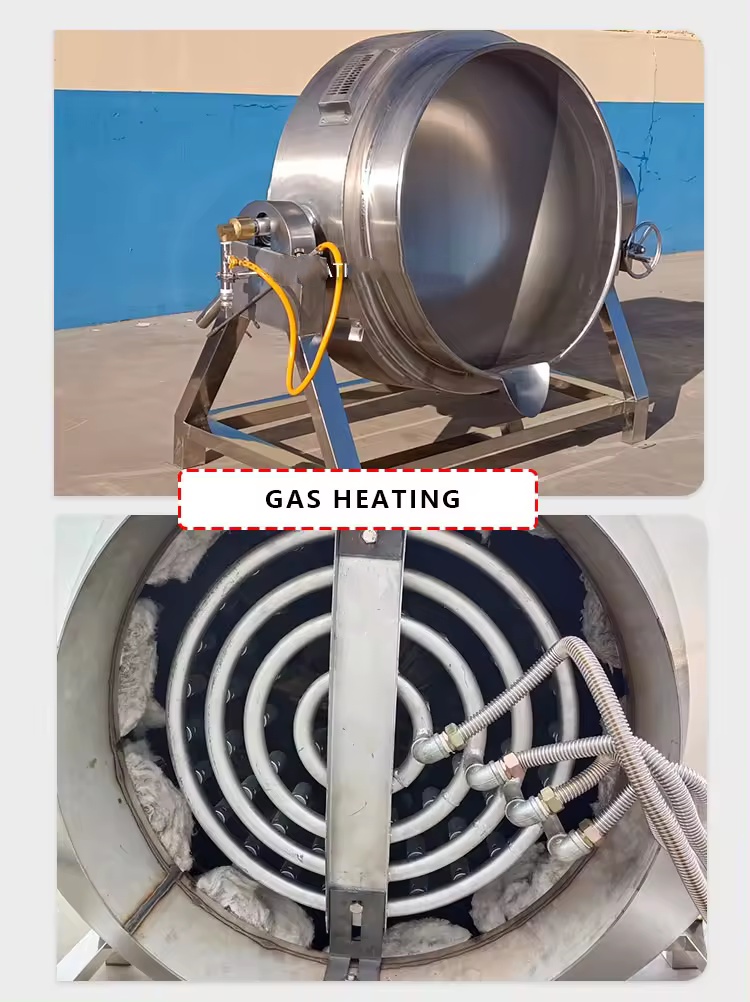

Multiple Heating Options

Supports electric heating, steam heating, and gas heating. Customers can choose based on on-site energy supply (e.g., steam heating for factories with boilers, electric heating for small canteens).

Efficient Uniform Heating

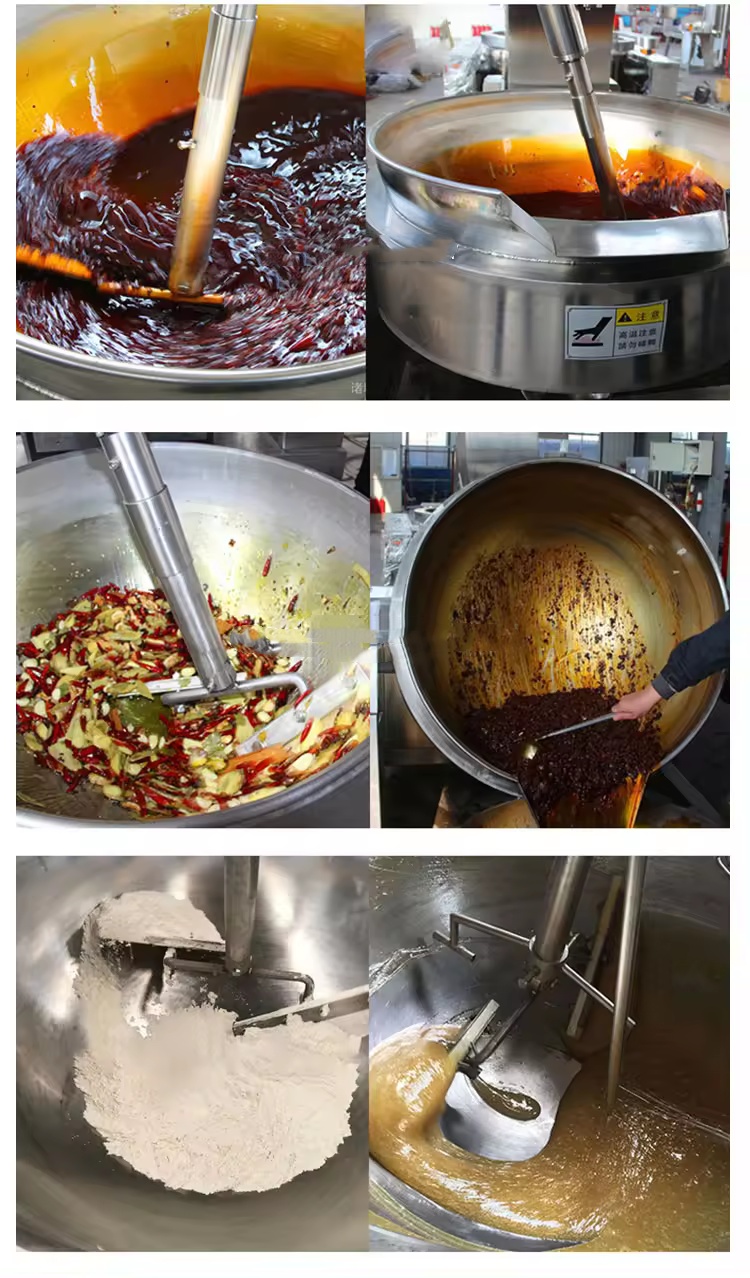

The double-layer spherical structure maximizes heating area (up to 2.3 m² for large models), ensuring fast boiling and no local overheating—ideal for both liquids (sauces) and solids (stewed meat).

90-Degree Tilting Discharge

The pot body tilts freely to 90 degrees, allowing complete discharge of materials without residue, reducing waste and simplifying post-use cleaning.

Optional PTFE Stirrer

Comes with an optional PTFE stirrer (high-temperature resistant) that mixes ingredients during heating—perfect for thick sauces, jams, or porridge.

Technical Specifications

Model | Volume(L) | | | | | Dimension (MM) | Weight(KG) |

HYL50 | 50 | | | | | 1050*800*950 | 90 |

HYL100

| 100 | | | | | 1150*900*950 | 105 |

HYL200

| 200 | | | | | 1250*1100*950 | 135 |

HYL300

| 300 | | | | | 1350*1100*1100 | 155 |

HYL400

| 400 | | | | | 1450*1200*1100 | 190 |

HYL500 | 500 | | | | | 1550*1300*1200 | 255 |

HYL600 | 600 | | | | | 1650*1400*1200 | 370 |

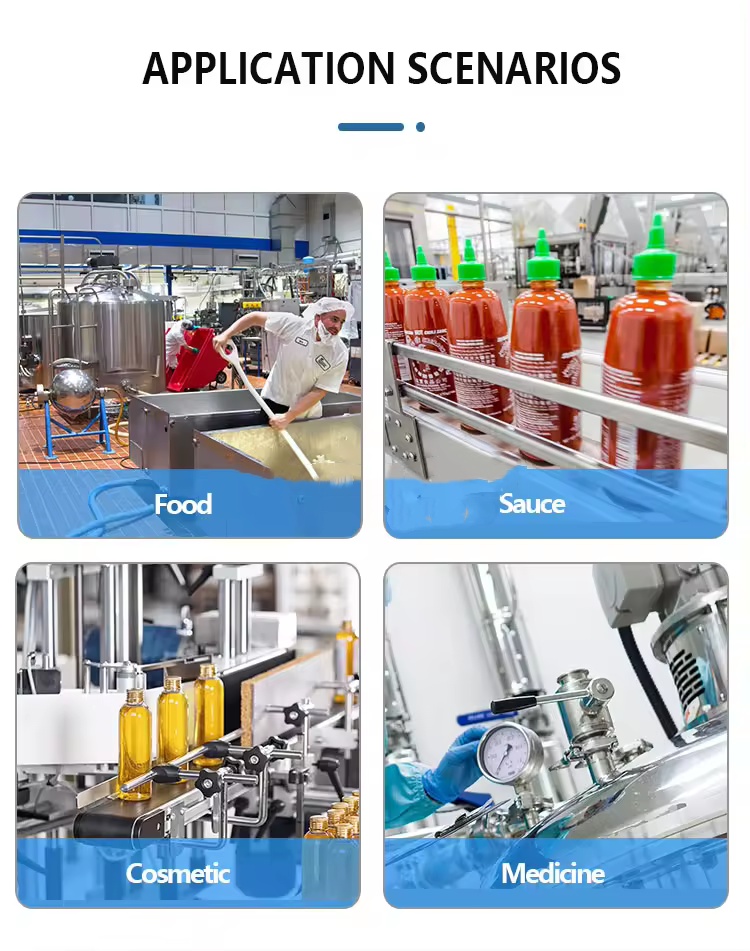

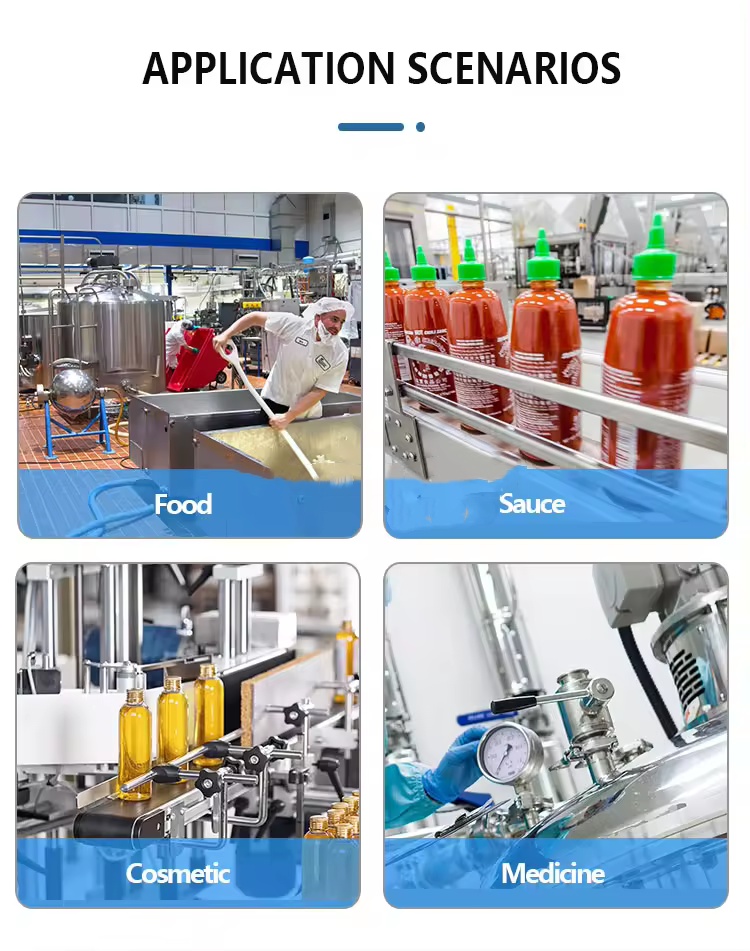

Application Areas

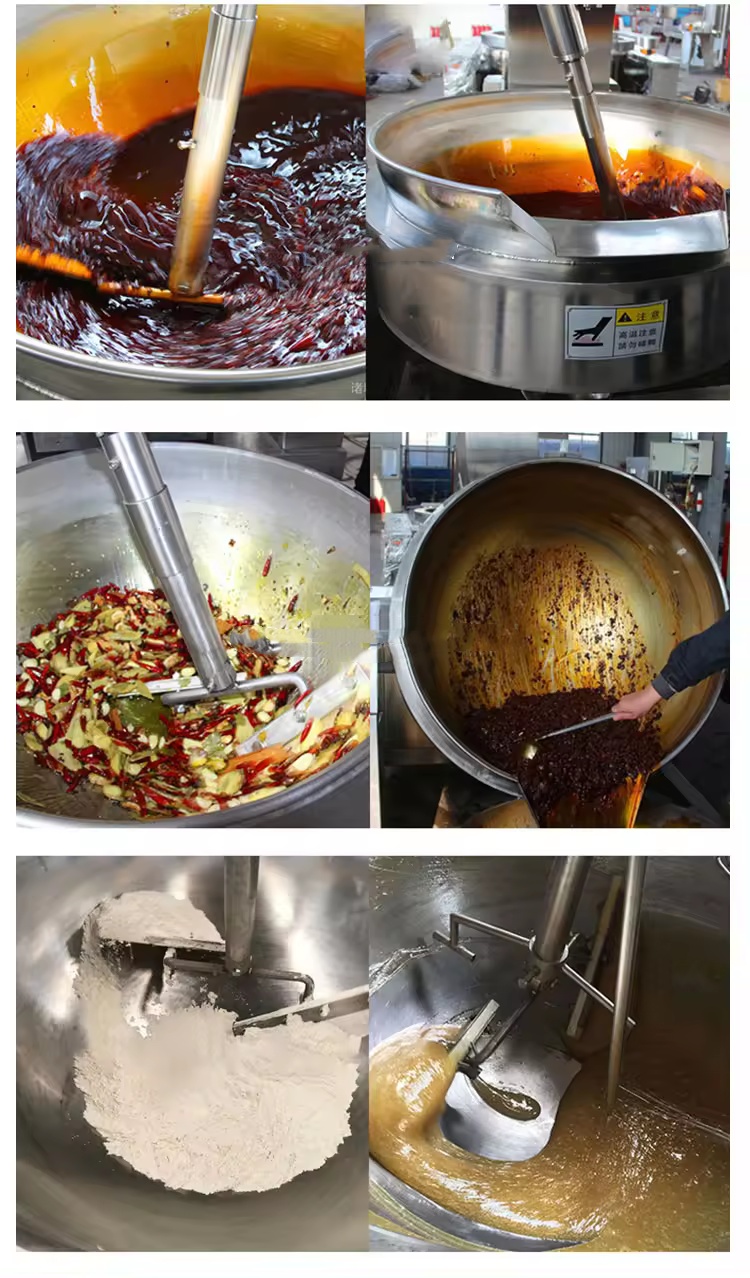

Food Processing Plants

Used for sauce processing (tomato sauce, chili sauce), canning (meat/fruit cans), and jam production—uniform heating ensures consistent product quality.

Large Canteens & Restaurants

Cooks large batches of soup, stewed meat, or porridge, saving 50% of time compared to traditional stoves and meeting the needs of 100+ people.

Bakery & Confectionery

Melts butter, chocolate, or sugar syrup at precise temperatures (±2℃), preventing burning and preserving the texture of pastries.

Pharmaceutical & Cosmetic Sectors

Heats small batches of liquid raw materials (e.g., herbal extracts for cosmetics) while adhering to hygiene standards.

Operation & Safety

Easy Operation Steps

Add ingredients to the pot and close the lid (if needed);

Select heating method and set temperature via the centralized controller;

Start heating—activate the stirrer (if equipped) for mixing;

After cooking, use the discharge handwheel to tilt the pot and pour out materials.

Safety Guarantees

Pressure control valve for steam heating to prevent overpressure;

Heat-resistant handle on the tilting mechanism to avoid burns;

Grounding protection for electrical components to prevent leakage.

Customization Support

HUIYILAI provides flexible customization:

Customizable volume (over 1000L for large factories);

Custom stirrer types (anchor stirrers for thick sauces, propeller stirrers for liquids);

Combined heating methods (e.g., electric + steam) for backup energy;

Optional non-stick inner coating for easier cleaning.