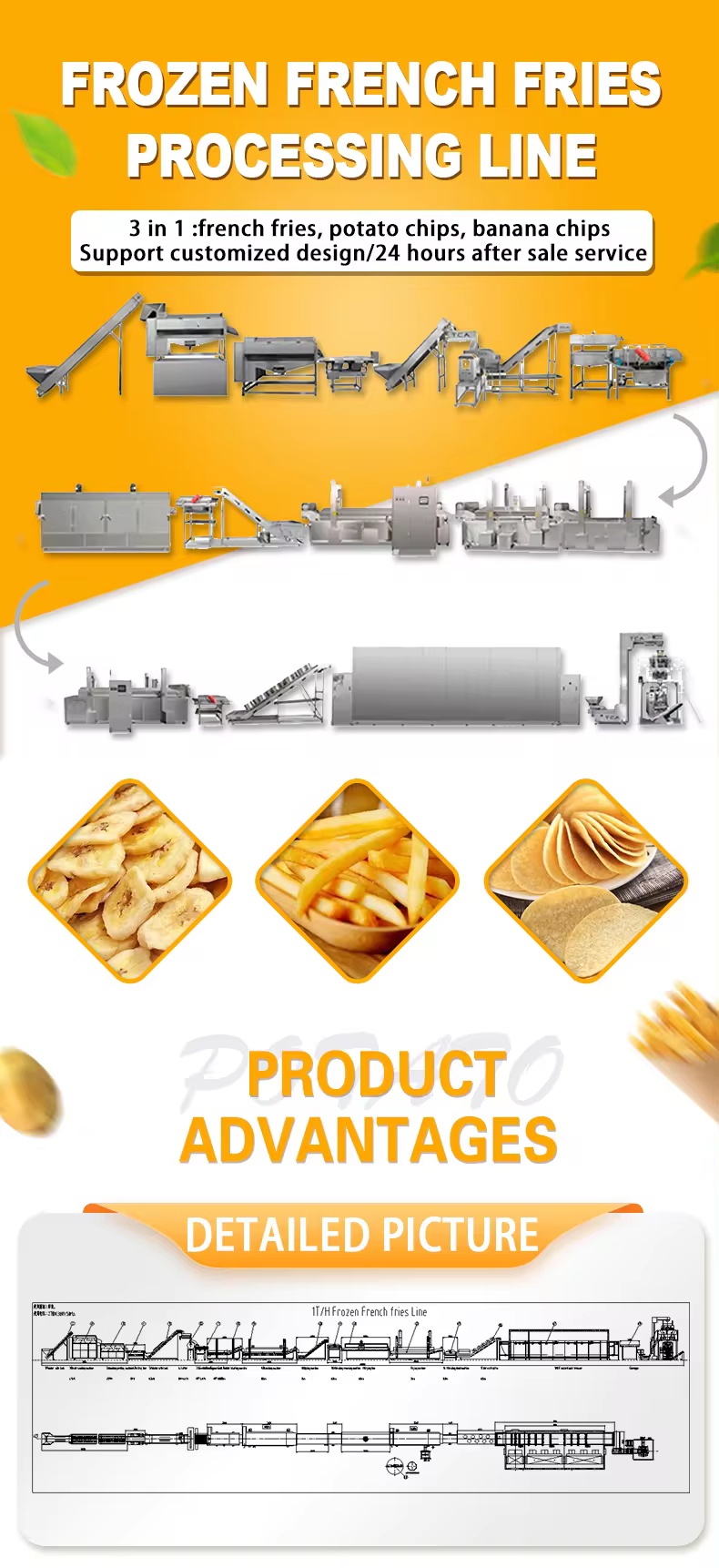

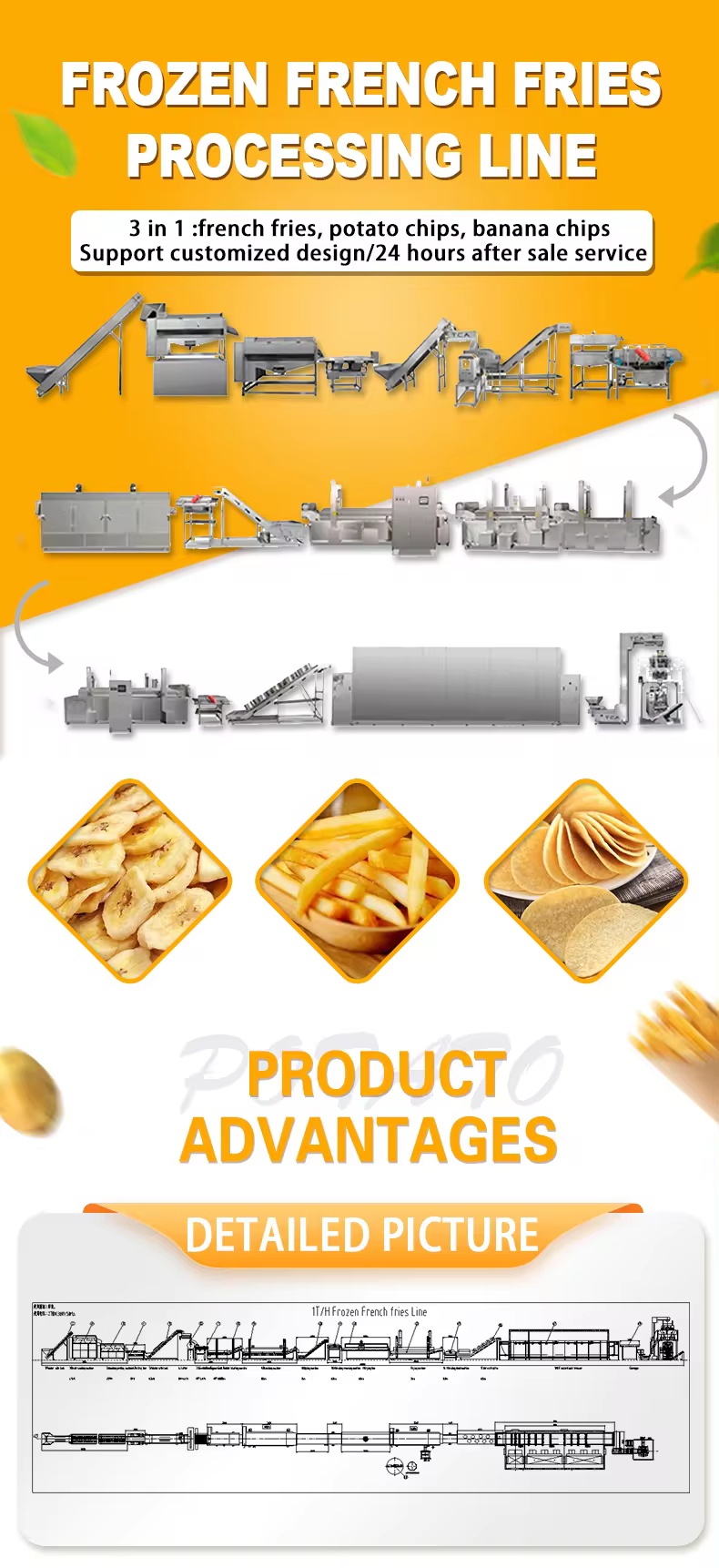

1000kg/h Fully-automatic French Frying Line for Potato Chips

This frying line for potato chips is a device for producing crispy potato chips, and the entire production line is fully automated. The main production process of the French fries line is potato cleaning and peeling, potato slicing, blanching, dehydration, frying, seasoning, and packaging. Each process is produced by professional machines. The output of this production line is 1000kg/h, we have production lines with different outputs according to your demand.

Automatic Potato Chips & Frozen French Fries Processing Line (1000kg/h) - Product Details

1. Product Overview (Key Points)

3-in-1 Multifunctional Capacity: Processes 1000kg/h of finished products, supporting 3 core outputs—frozen French fries, potato chips, and banana chips (no need for separate lines, reducing equipment investment by 40%)

Fully Automatic Integration: Covers 8 key processes for frozen fries & chips—potato washing, peeling, slicing/stick-cutting, bubble washing, blanching, frying, deoiling, and IQF fluidized quick freezing (meets both fresh chip and frozen food demands)

Customization & After-Sales: Supports tailor-made design (e.g., adjusting line length for small factories, adding stick-cutting modules for fries) and 24/7 after-sales service (global response within 1 hour)

Build & Compliance: Entire line constructed with 304 food-grade stainless steel (thickness 2-5mm); meets FDA 21 CFR Part 177.1550, CE, GB 4806.9-2016, and HACCP standards—ideal for both fresh snack supply and frozen food export

Core Advantages: Cuts labor costs by 60% (1 operator vs. 10 manual workers), extends frying oil lifespan by 30%, ensures ≤5% variation in product thickness/taste, and enables seamless switch between fries/chips/banana chips in 30 minutes

2. Product Description

For snack factories, frozen food enterprises, and export-oriented suppliers, two critical pain points often limit growth: single-function equipment (needing separate lines for chips and fries) and inefficient pre-frozen processing. A mid-sized frozen food factory might use 2 separate lines—one for French fries, one for chips—tying up $100,000+ in capital and wasting 50% of floor space. A banana chip supplier could struggle with uneven blanching, leading to 20% of products spoiling during freezing. Our 3-in-1 Automatic Potato Chips & Frozen French Fries Processing Line solves these challenges by unifying multiple outputs and optimizing pre-frozen workflows.

Run your hand along the line’s bubble washing tank—you’ll feel the smooth 304 stainless steel interior, with no crevices where starch or pulp can hide. Load 1500kg of raw potatoes into the hopper, tap the 10-inch touchscreen to select "Frozen French Fries" (10mm×10mm sticks, 85℃ blanching, -35℃ IQF freezing), and press "start." The line hums softly (70dB) as potatoes move through each stage: spiral washing/peeling (adjustable speed for different potato varieties), stick-cutting (instead of slicing for chips), dual bubble washing (30-40s each, stripping excess starch to prevent oil clumping), dual blanching (65-90℃ hot water, destroying enzymes to keep fries crisp post-freezing), frying (170℃ for 2 minutes), deoiling (300rpm centrifugal spin), and finally IQF fluidized freezing (-35℃ in 10 minutes, locking in freshness).

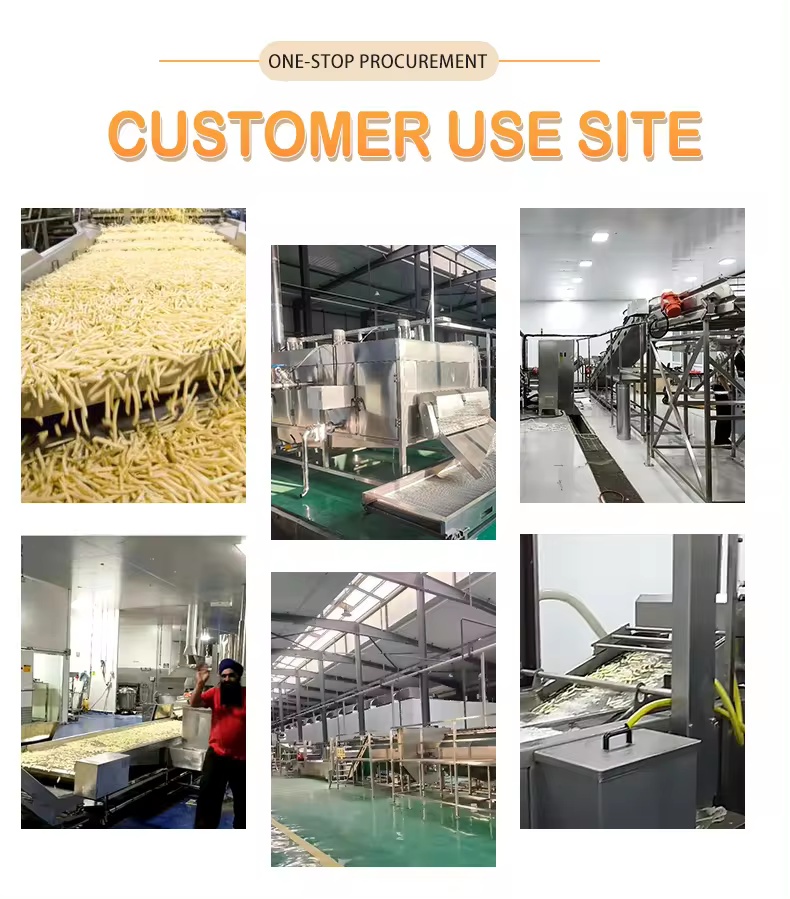

After 45 minutes, the first batch of frozen French fries emerges—golden, uniform, and ready for packaging. A frozen food client in Canada, supplying 500+ supermarkets, reported that this 3-in-1 line replaced 2 old lines, cutting floor space usage by 45% and reducing monthly electricity costs by $3,000. A banana chip supplier in Thailand switched to this line for blanching and freezing, slashing spoilage rates from 20% to 3% and doubling their export volume to Europe.

3. Product Features & Highlights

3.1 3-in-1 Multifunctional Design: One Line, Three Outputs

Unlike single-purpose lines, our design lets you switch between frozen French fries, potato chips, and banana chips with minimal adjustments—saving equipment costs and space:

Frozen French Fries Mode: Swap slicer blades for a 10mm×10mm (adjustable 8-12mm) stick-cutting module; activate dual blanching (65-90℃) and IQF freezing (-35℃) to meet frozen food standards.

Potato Chips Mode: Revert to 1-3mm slicer blades; disable IQF freezing (keep deoiling for fresh chips) and adjust frying time to 1-3 minutes.

Banana Chips Mode: Add a pulp-separating attachment to the washing tank; lower blanching temperature to 65-75℃ (to preserve banana sweetness) and extend freezing time by 2 minutes (bananas have higher moisture content).

Switching between modes takes 30 minutes (blade/attachment replacement + parameter adjustment)—no need for downtime or extra labor. A client in Brazil uses all three modes to supply both fresh chips to local markets and frozen fries/banana chips to export buyers, increasing revenue by 60%.

3.2 Key Equipment Advantages: Precision & Efficiency

Each module in the line is engineered for B2B productivity and quality, with standout features for the 7 core components:

01 Washing Peeling Machine

Adjustable Speed: Spiral vane speed (30-60rpm) and rolls speed (20-40rpm) are touchscreen-adjustable—slower for soft potatoes (to avoid bruising), faster for firm varieties (to save time).

Efficient Filtration: Built-in filter separates potato peel and sand from washing water, recycling 50% of water and reducing sewage discharge.

Spray-Assisted Peeling: A 80-bar spraying device rinses potatoes during peeling, ensuring 98% peel removal (no manual touch-ups needed).

02 Potato Chips Slicer

Smooth Cutting: 12 stainless steel blades (replaceable) cut with 0.1mm precision, resulting in smooth chip surfaces (no jagged edges that trap oil).

Fast & Labor-Saving: Cuts 1500kg of peeled potatoes per hour—3x faster than manual slicing—and is easy to disassemble for cleaning (10 minutes to wipe blades and housing).

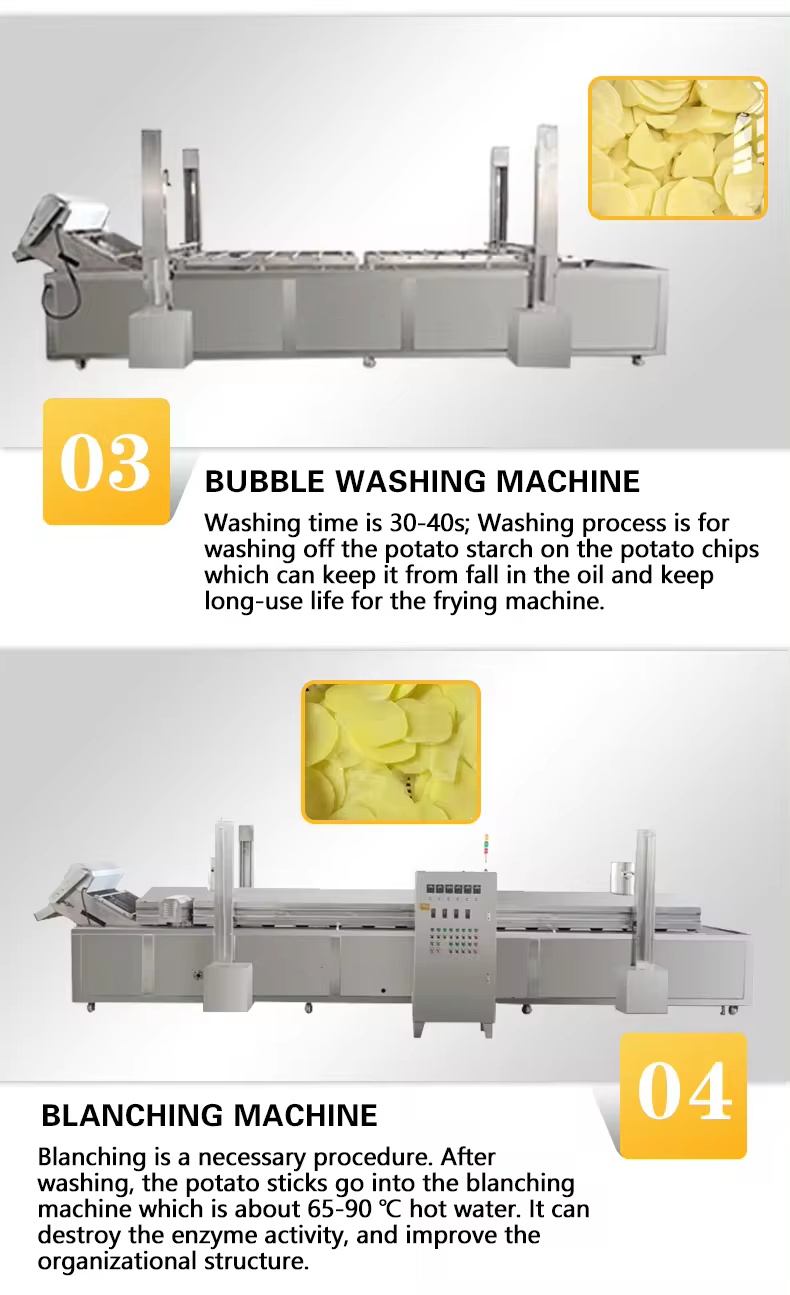

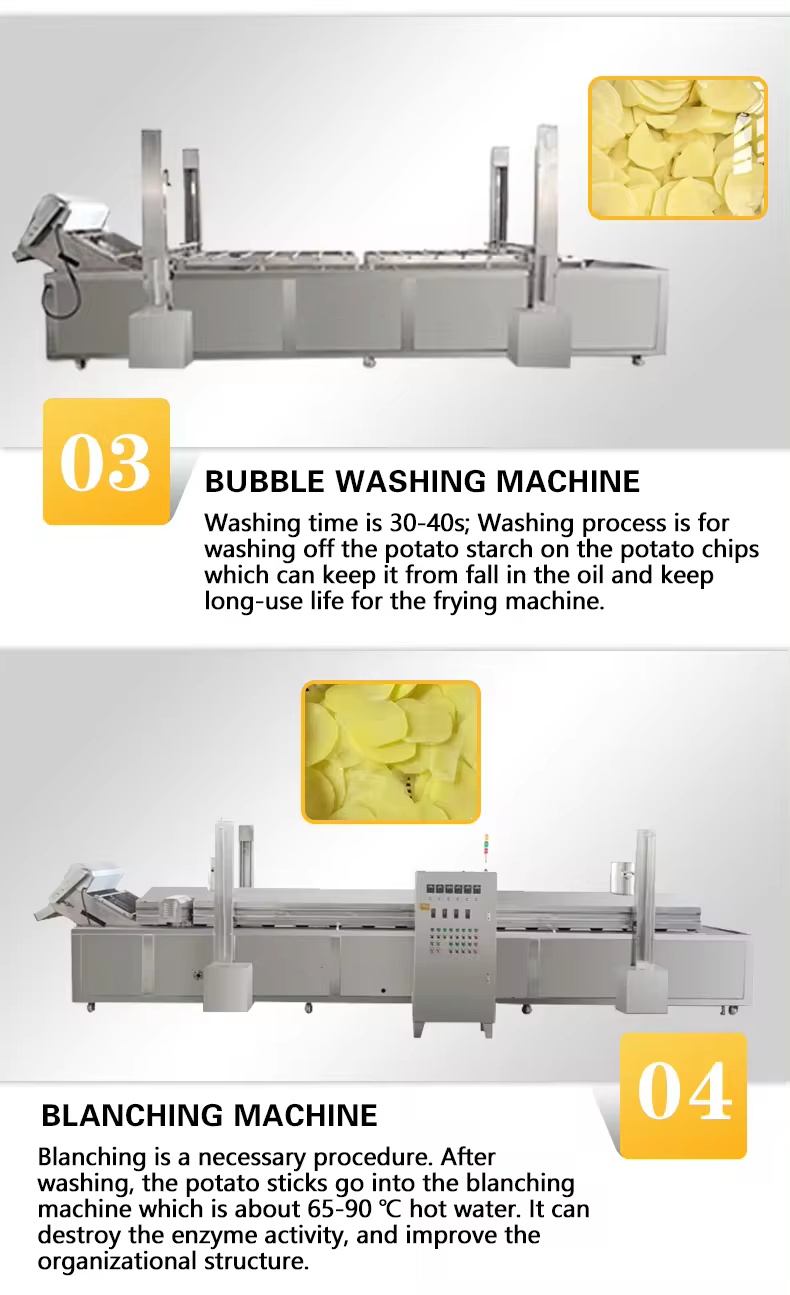

03 & 05 Bubble Washing Machine (Dual-Stage)

30-40s Washing Cycle: Each machine runs for 30-40 seconds, using high-pressure bubbles to scrub off starch from chips/sticks. The first wash removes 70% of surface starch; the second eliminates remaining residue—critical for preventing chips from sticking together in the fryer and extending oil lifespan by 30%.

Stainless Steel Mesh Belt: Conveys products gently (no scraping) and is corrosion-resistant, with a 5-year service life.

04 & 06 Blanching Machine (Dual-Stage)

Necessary Enzyme Destruction: 65-90℃ hot water (adjustable via PID control) destroys polyphenol oxidase (prevents browning) and amylase (improves chip/fry texture). For frozen fries, blanching at 85℃ for 2 minutes ensures crispness after thawing.

Improved Organizational Structure: Blanching softens potato cell walls, making fries/chips absorb seasoning more evenly and freeze/thaw without breaking.

07 IQF Fluidized Quick Freezer

Instant Freezing: Inner temperature reaches -35℃ (maintained via a 15kW refrigeration system), freezing products in 10-15 minutes—faster than traditional freezers (which take 30+ minutes). This "quick freeze" locks in moisture and nutrients, keeping fries crisp for 12 months in storage.

Low Energy Consumption: Cold consumption is around 131,580 kcal (153W), 20% lower than standard IQF freezers—saving $200+/month in electricity for 12-hour daily operation.

3.3 Customized Design & 24/7 After-Sales

We understand B2B needs vary—our line supports full customization:

Capacity Adjustment: Scale output to 500kg/h (small factories) or 1500kg/h (large enterprises) by adding/removing frying tanks or freezing zones.

Space Optimization: Shorten the line from 15m to 12m for factories with limited floor space (by overlapping the blanching and washing modules).

Localized Adaptations: Add voltage converters for 220V markets (e.g., US), or oil-type compatibility (palm oil for Southeast Asia, soybean oil for Europe).

Our 24/7 after-sales service complements customization: a client in Nigeria had a sudden IQF freezer failure during peak frozen fry season—our technician responded via video call within 1 hour, guided on-site staff to replace a faulty sensor, and restored operation in 2 hours (avoiding $15,000 in lost sales).

4. Application Scenarios

The line’s 3-in-1 design and frozen processing capability make it ideal for 3 key B2B scenarios:

4.1 Frozen Food Enterprises

Enterprises supplying frozen French fries to fast-food chains (e.g., McDonald’s, KFC) or supermarkets rely on consistent freezing and long shelf life. The line’s IQF freezer (-35℃) ensures fries meet "12-month frozen storage" standards, while dual blanching prevents browning. A client in the UK supplies 100+ KFC locations, using the line to produce 12,000kg of frozen fries daily—with zero complaints about texture or taste.

4.2 Multi-Product Snack Factories

Factories needing to diversify outputs (fresh chips + frozen fries + banana chips) use the 3-in-1 mode to reduce costs. A factory in India uses daytime hours for fresh chips (local markets) and nighttime for frozen fries/banana chips (export), maximizing line usage and revenue. The line’s adjustable parameters let them tailor each product to buyer needs—thin chips for India, thick fries for the Middle East, sweet banana chips for Europe.

4.3 Export-Oriented Suppliers

Suppliers exporting to EU/US frozen food markets need compliance and traceability. The line’s 304 stainless steel build and IQF freezing meet EU food safety standards (EC No. 853/2004), while the PLC logs all freezing temperatures and blanching times for audit reports. A Chinese supplier passed a US FDA inspection on the first try, thanks to the line’s documentation and hygiene design—doubling their frozen fry exports to the US.

5. Working Principle

The line’s efficiency comes from seamless integration of 8 processes, optimized for both fresh and frozen products:

-

Washing & Peeling Stage:

Raw potatoes enter the washing peeling machine. Spiral vanes (30-60rpm) and rolls (20-40rpm) scrub and peel potatoes, while a spray device rinses away peel residue. A filter separates peel/sand from water, recycling it to the tank.

-

Cutting Stage:

For French fries: A stick-cutting module (8-12mm adjustable) cuts potatoes into uniform sticks.

For potato chips: The slicer (1-3mm) produces thin slices.

For banana chips: A pulp-separating attachment first removes banana pulp, then the slicer cuts into 2mm slices.

-

First Bubble Washing Stage:

The 03 Bubble Washing Machine runs for 30-40s, using bubbles to remove 70% of surface starch from cuts—preventing oil clumping in frying.

-

First Blanching Stage:

The 04 Blanching Machine uses 65-90℃ hot water to destroy enzymes (prevents browning) and soften cell walls. For fries, temperature is set to 85℃; for banana chips, 65-75℃.

-

Second Bubble Washing Stage:

The 05 Bubble Washing Machine completes a second 30-40s wash, eliminating remaining starch—critical for extending oil life and ensuring even frying.

-

Second Blanching Stage:

The 06 Blanching Machine repeats the process at the same temperature, reinforcing enzyme destruction and texture improvement (no softening from over-blanching).

-

Frying & Deoiling Stage:

A PID-controlled fryer (160-180℃) cooks products for 1-3 minutes. A centrifugal deoiler (300rpm) then reduces oil content to ≤8% (fresh chips) or ≤10% (frozen fries—higher oil content prevents freezer burn).

-

IQF Freezing Stage (Frozen Modes Only):

The 07 IQF Fluidized Quick Freezer lowers temperature to -35℃, freezing products in 10-15 minutes. A fluidized air system ensures each fry/chip freezes individually (no clumping), ready for packaging.

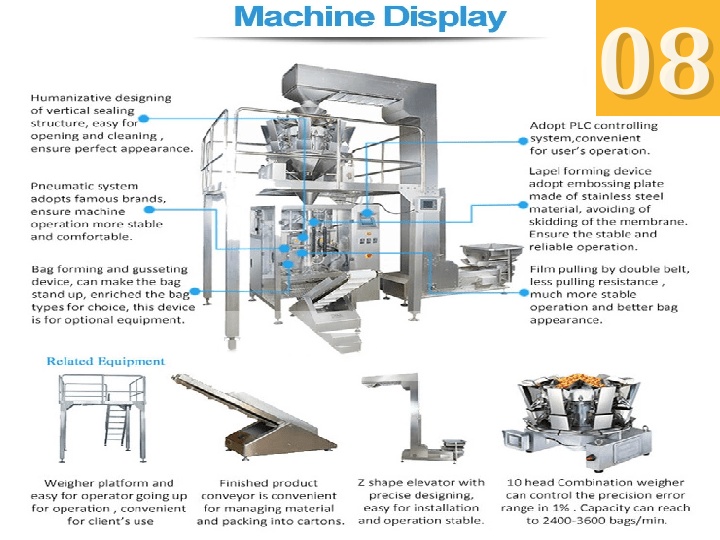

6. Operation Process

Step 1: Pre-Operation Setup (10 Minutes)

Select Mode: Tap the touchscreen to choose "Frozen French Fries," "Potato Chips," or "Banana Chips"—the line auto-adjusts parameters (e.g., cuts, temperature, freezing) or prompts for attachment replacement (e.g., stick-cutting module for fries).

Check Equipment: Verify water level in washing/peeling machines, oil level in the fryer, and refrigerant level in the IQF freezer. Inspect blades/rolls for wear (replace if needed).

Calibrate Sensors: Ensure blanching temperature (±0.5℃) and IQF temperature (±1℃) are accurate—use a standard thermometer to confirm.

Step 2: Load & Start (2 Minutes)

Load raw materials into the hopper (1500kg/h max for potatoes; 1200kg/h for bananas).

Press "start"—the line runs automatically, with real-time data (temperature, output, time remaining) displayed on the screen. Alerts (e.g., low water, blade blockage) appear with solutions (e.g., "Refill washing tank" or "Clear slicer jam").

Step 3: Monitor & Switch Modes (As Needed)

For multi-shift production, switch modes after a batch ends: turn off the line, replace blades/attachments (e.g., slicer to stick-cutting), adjust parameters via the touchscreen, and restart.

Step 4: Post-Production Cleaning (20 Minutes)

Press "clean"—the line drains oil/water, rinses all modules with high-pressure water, and heats the fryer to 200℃ for 10 minutes (sanitization).

Disassemble the slicer, bubble washing mesh belts, and IQF freezer’s air filter for deep cleaning (use neutral detergent—avoid steel wool).

Export production data (batch logs, temperature records) via USB for audits.

7. Maintenance & Care

Daily Maintenance (20 Minutes/Shift)

Clean All Modules: Rinse the washing peeling machine’s filter (remove peel/sand), wipe slicer blades (remove starch), and drain the fryer’s oil (filter and reuse if clean).

Check IQF Freezer: Remove frost from the freezer’s inner walls (use a plastic scraper—no metal tools) to maintain -35℃ efficiency.

Inspect Belts: Ensure bubble washing machine mesh belts are tight (adjust tension if loose) to prevent product jams.

Weekly Maintenance (1 Hour)

Replace Filters: Swap the washing machine’s water filter and fryer’s oil filter—clogged filters reduce efficiency by 25%.

Lubricate Moving Parts: Apply food-grade grease to spiral vanes, slicer gears, and conveyor bearings (10g per point) to prevent rust.

Calibrate IQF Freezer: Use a cryogenic thermometer to verify the freezer’s inner temperature—adjust refrigerant if it deviates from -35℃ by ±2℃.

Monthly Maintenance (2 Hours)

Inspect Blades & Rollers: Replace slicer blades (after 50 hours of use) and washing peeling machine rolls (after 100 hours) to ensure clean cuts/peeling.

Test Blanching PID: Run a test batch at 80℃—confirm the blanching machine maintains temperature within ±0.5℃ (inaccurate temps cause uneven texture).

Check IQF Refrigerant: Top up refrigerant (R404A) if levels are low—low refrigerant increases energy consumption by 30%.

Annual Overhaul

8. Why Choose Us?

8.1 Multifunctional Expertise & Customization

We’ve specialized in food processing lines for 15 years, with a 18-person R&D team that developed the 3-in-1 design to solve B2B "single-line limitation" pain points. We hold 12 patents for this line, including "Dual-Stage Blanching for Frozen Fries" (CN202321876543.2) and "IQF Fluidized Freezer Energy-Saving Design" (CN202321876544.7).

Customization is our strength: a client in a small Thai factory needed a 12m line (instead of 15m) to fit their space—we overlapped the blanching and washing modules, maintaining 1000kg/h output without sacrificing quality.

8.2 Rigorous Quality Control

Every line undergoes 5 rounds of testing:

Material Test: 304 stainless steel parts are soaked in 5% salt water for 24 hours (no rust allowed).

Function Test: Run all 3 modes (fries/chips/banana chips) for 8 hours—output must be 1000kg/h ±5%, IQF temperature -35℃ ±1℃.

Safety Test: Simulate 15 error scenarios (e.g., IQF overheating, fryer oil leak) to ensure automatic shutdown.

Hygiene Test: Swab all food-contact parts after cleaning—microbial count <10 CFU/g.

Freeze-Thaw Test: Freeze fries for 12 months, then thaw—texture must remain crisp (no sogginess).

8.3 24/7 Global After-Sales

1-Hour Response: Our team answers calls/emails 24/7—even on holidays. A client in Australia had a blanching machine failure at 2 AM; we guided them to replace a sensor via video call, restoring production in 1.5 hours.

Fast Spare Parts: We stock 2000+ parts (slicer blades, IQF sensors, washing filters) in 12 global warehouses—most arrive in 24-48 hours.

On-Site Support: For major issues, technicians arrive within 72 hours (12 service centers worldwide). A client in Kenya needed IQF freezer maintenance—our technician flew in, serviced the unit, and trained staff for free.

9. FAQ

Q1: Can the line handle other root vegetables (e.g., sweet potatoes, carrots) for fries?

A1: Yes—we offer a "root vegetable kit" (custom attachment) that adjusts the washing peeling machine’s roll speed (slower for sweet potatoes, which have thinner skins) and blanching temperature (75-85℃ for sweet potatoes to preserve color). The stick-cutting module can also be resized to 8mm×8mm for smaller carrot fries.

Q2: How much space does the line need, and can it be customized for smaller factories?

A2: Standard size is 15m (L) × 3m (W) × 2.5m (H). For smaller factories, we can shorten it to 12m (by overlapping blanching/washing) or 10m (reducing fryer tank size to 600L, output 800kg/h). We provide a 2D floor plan to fit your space.

Q3: What’s the IQF freezer’s power consumption and refrigerant type?

A3: The IQF freezer uses 15kW power (cold consumption ~131,580 kcal) and R404A refrigerant (environmentally friendly, compliant with EU F-Gas regulations). For 12-hour daily use, it costs ~$15/day in electricity (varies by region).

Q4: How long does it take to install the line, and do you provide training?

A4: Installation takes 3-5 days (2 technicians). We train 5 operators for free: 2 hours of theory (parameter setting, safety) + 8 hours of hands-on practice (mode switching, cleaning). We also provide a video training library for new staff.

The nutrients contained in potatoes are very comprehensive. In addition to high carbohydrates, there are also various nutrients such as protein, vitamin C, vitamin BI, carotene, etc. The protein of potatoes is special, and the calories per 100 grams of potatoes are only equivalent to 1/2 of eggs and milk of the same quality. Potatoes can be used as both vegetables and staple food. The biggest advantage of potatoes is that they can still maintain their original flavor after being processed into food.

This 1000kg/h Fully-automatic French Frying Line for Potato Chips mainly include followings product process:

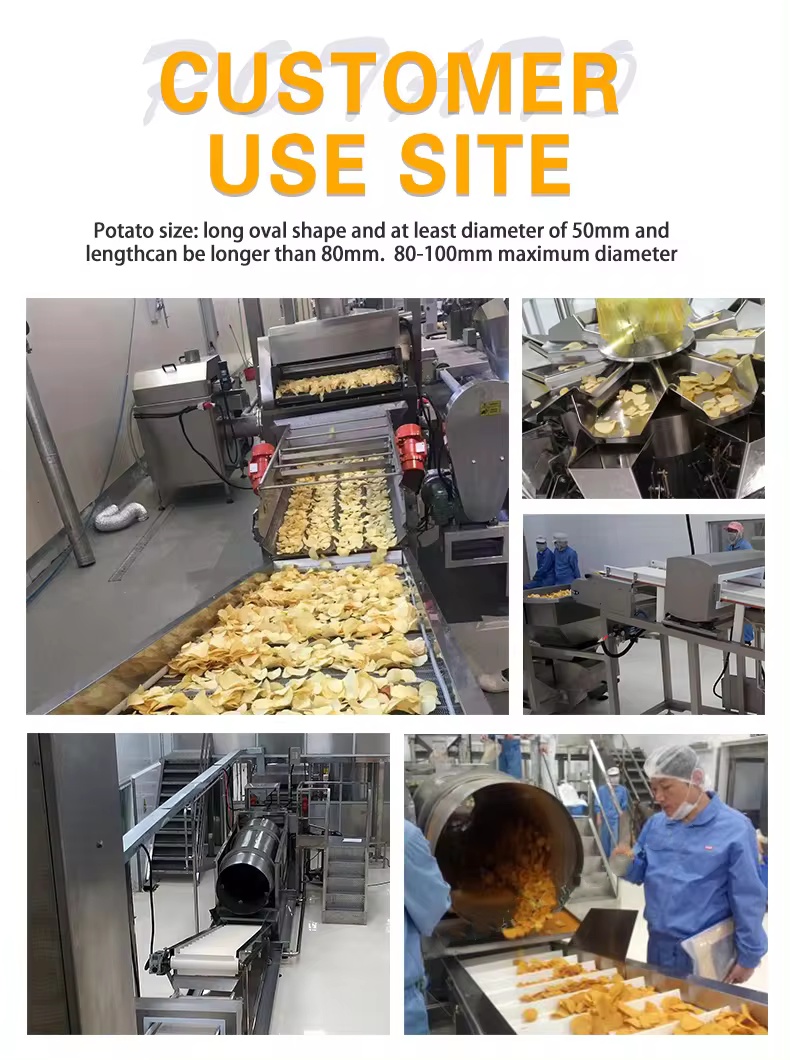

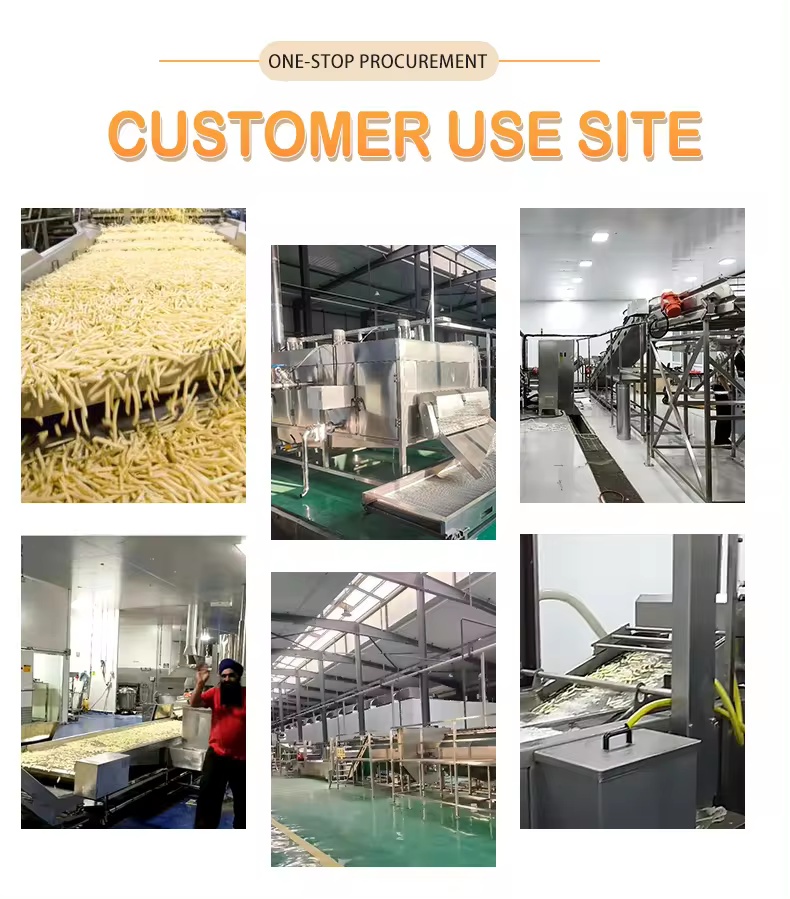

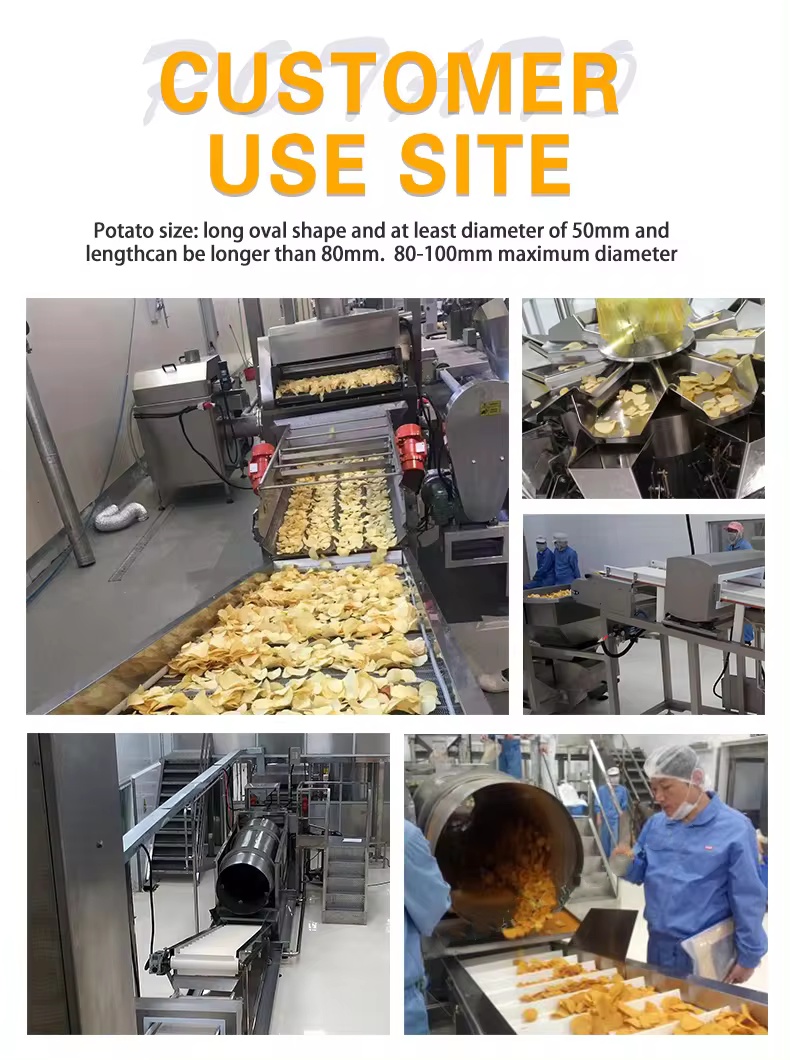

Customer pot Show:

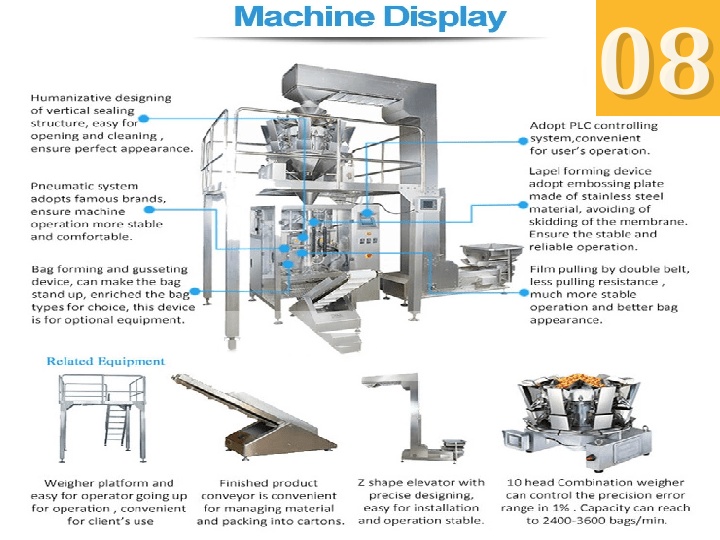

Packaging & Shipping: