Overview

The Vortex Cleaning Assembly Line optimizes pre-processing for potatoes, cassava, carrots, and ginger, combining high-pressure washing with gentle agitation to remove soil, wax, and surface contaminants. Designed for root vegetable processors, it handles 1-3 tons/h of dirty produce, featuring adjustable cleaning intensity and water recycling to minimize waste.

Features

Dual-Chamber Vortex System:

First Chamber: 500rpm vortex drum with rubber baffles loosens stubborn dirt (clay, sand) from crevices.

Second Chamber: 300rpm polishing drum with food-grade brushes removes residual debris and wax coatings.

High-Efficiency Water Recycling: 90% of washing water reused via a three-stage filtration system (50μm, 20μm, 5μm), reducing freshwater consumption to 0.8m³/ton.

Adjustable Nozzle Array: 360° rotating water jets (100-300kPa pressure) target all produce surfaces, with lower pressure (50kPa) for delicate ginger and higher pressure (250kPa) for dirty cassava.

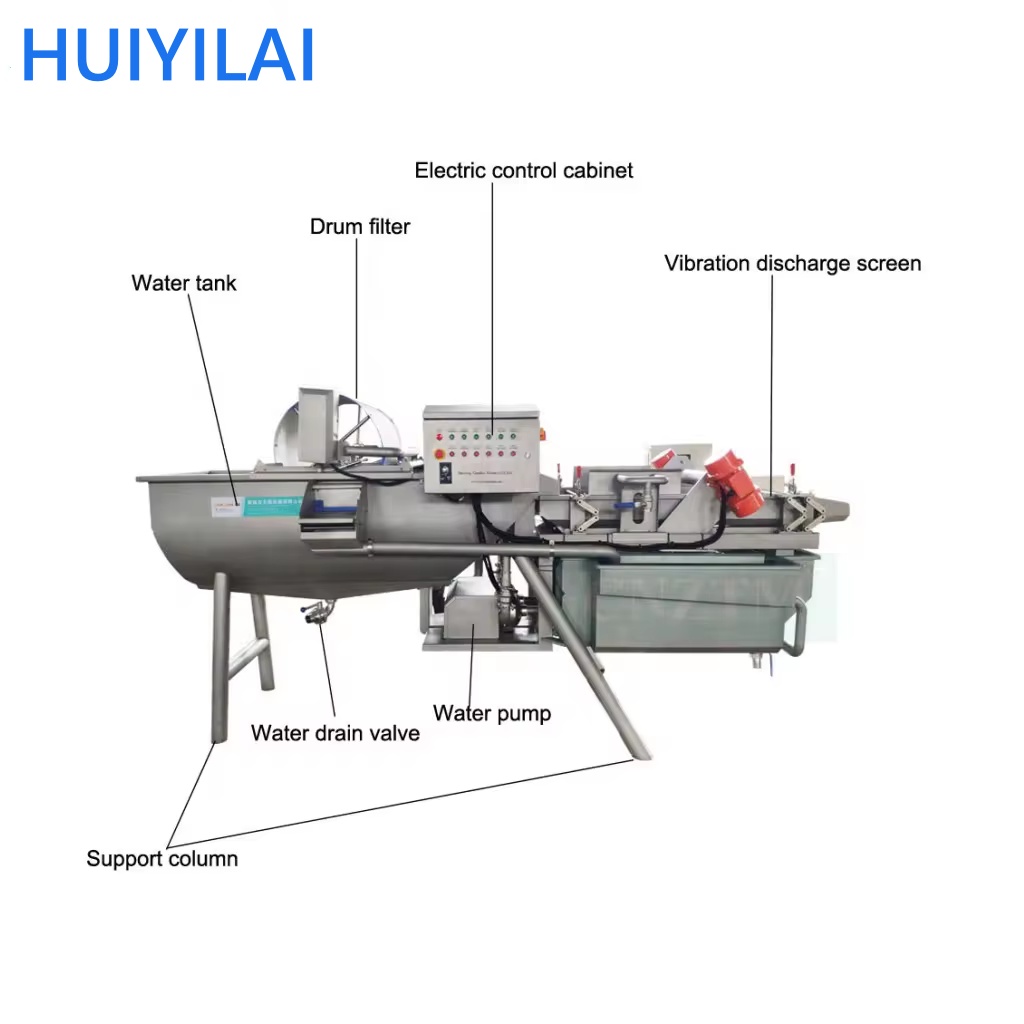

Anti-Compression Design: Spiral conveyor with 50mm spacing prevents bruising, while the inclined drum (15° angle) ensures continuous material flow without jams.

Hygienic Elevation: Stainless steel legs (400mm height) facilitate floor cleaning, with quick-release drain valves for complete water evacuation during CIP.

Application

Potato Processing Plants: Preps tubers for chips, fries, and starch extraction, achieving <0.1% residual soil after cleaning.

Cassava & Yam Factories: Removes tough outer dirt and cyanogenic residues from cassava roots, meeting FAO standards for safe edible processing.

Ginger & Carrot Producers: Gentle cleaning preserves skin integrity for fresh market produce, with optional brush hardness (soft for ginger, medium for carrots).

Organic Farms: Chemical-free cleaning using only water and air agitation, compliant with USDA NOP and EU Organic regulations.

FAQ

Q: Can it clean sprouted potatoes?

A: Yes, the vortex action removes sprouts ≤5mm without damaging the tuber; larger sprouts require pre-trimming.

Q: What is the minimum produce size?

A: Processes items ≥30mm in diameter; smaller roots (e.g., baby carrots) require optional mesh inserts to prevent slippage.

Q: How is water temperature controlled?

A: Integrated heat exchanger maintains washing water at 15-25°C, preventing enzyme activation and preserving produce crispness.